A method for adjusting an ultrasonic probe

A technology of ultrasonic probe and adjustment method, which is applied in ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, material analysis using sonic/ultrasonic/infrasonic wave, etc. simple issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

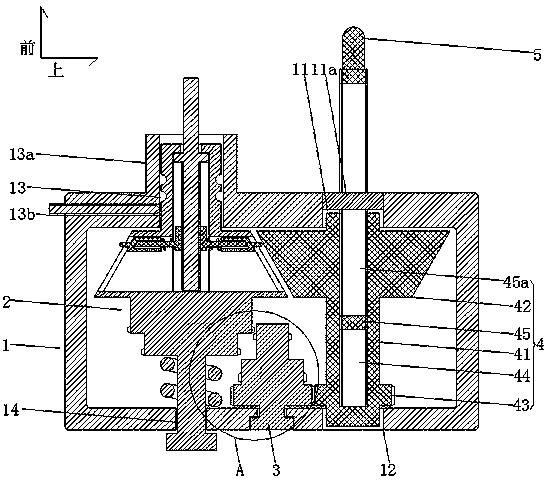

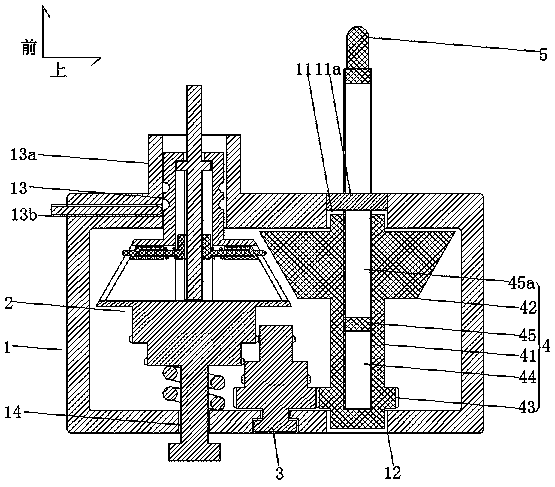

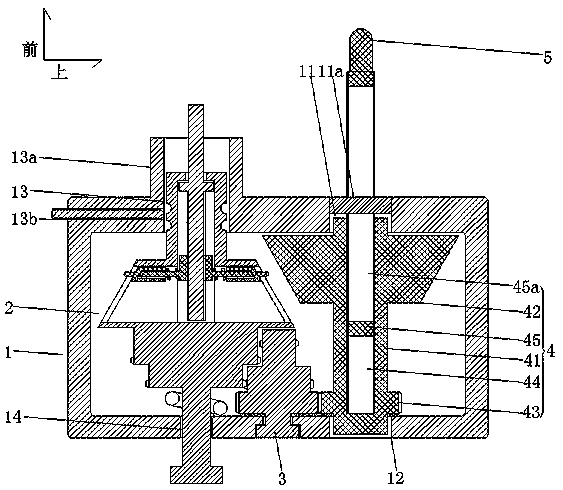

[0070] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0071] An ultrasonic probe adjustment method, using an ultrasonic probe handheld bracket for adjustment, the ultrasonic probe handheld bracket includes a handheld housing 1, an active element 2, a transmission element 3, a driven element 4, and an ultrasonic probe 5;

[0072] The handheld housing 1 is a hollow handheld housing, and the handheld housing 1 includes:

[0073] The front output hole 11 is located above the front end of the hand-held housing 1, and a limit cross bar 11a is arranged inside it;

[0074] The rear output hole 12 is located at the rear end surface of the hand-held housing 1 corresponding to the front output hole 11;

[0075] The front input hole 13 is located below the front end of the hand-held housing 1, the front end of the front input hole 13 is formed with an annular protective sleeve 13a, and the lower end of the hand-held housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com