Electric power fitting applied to overhead line

A technology for power fittings and overhead lines, which is used in overhead installation, electrical components, cable installation, etc., can solve problems such as damage at the connection between cables and fittings, lack of buffer unloading force, short-circuiting of adjacent cables, etc., to reduce power failures , Improve the scope of application and prevent the effect of cable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

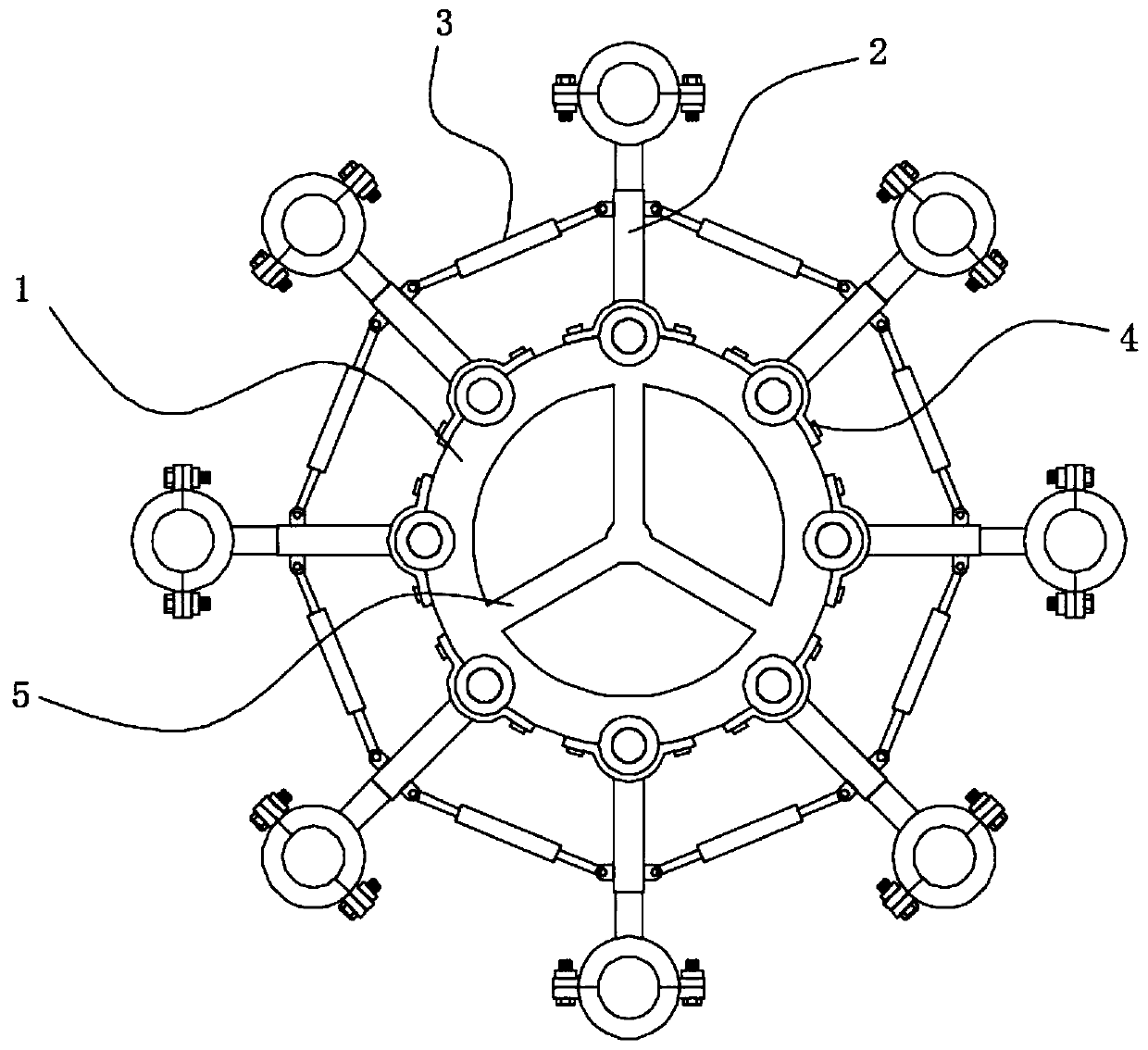

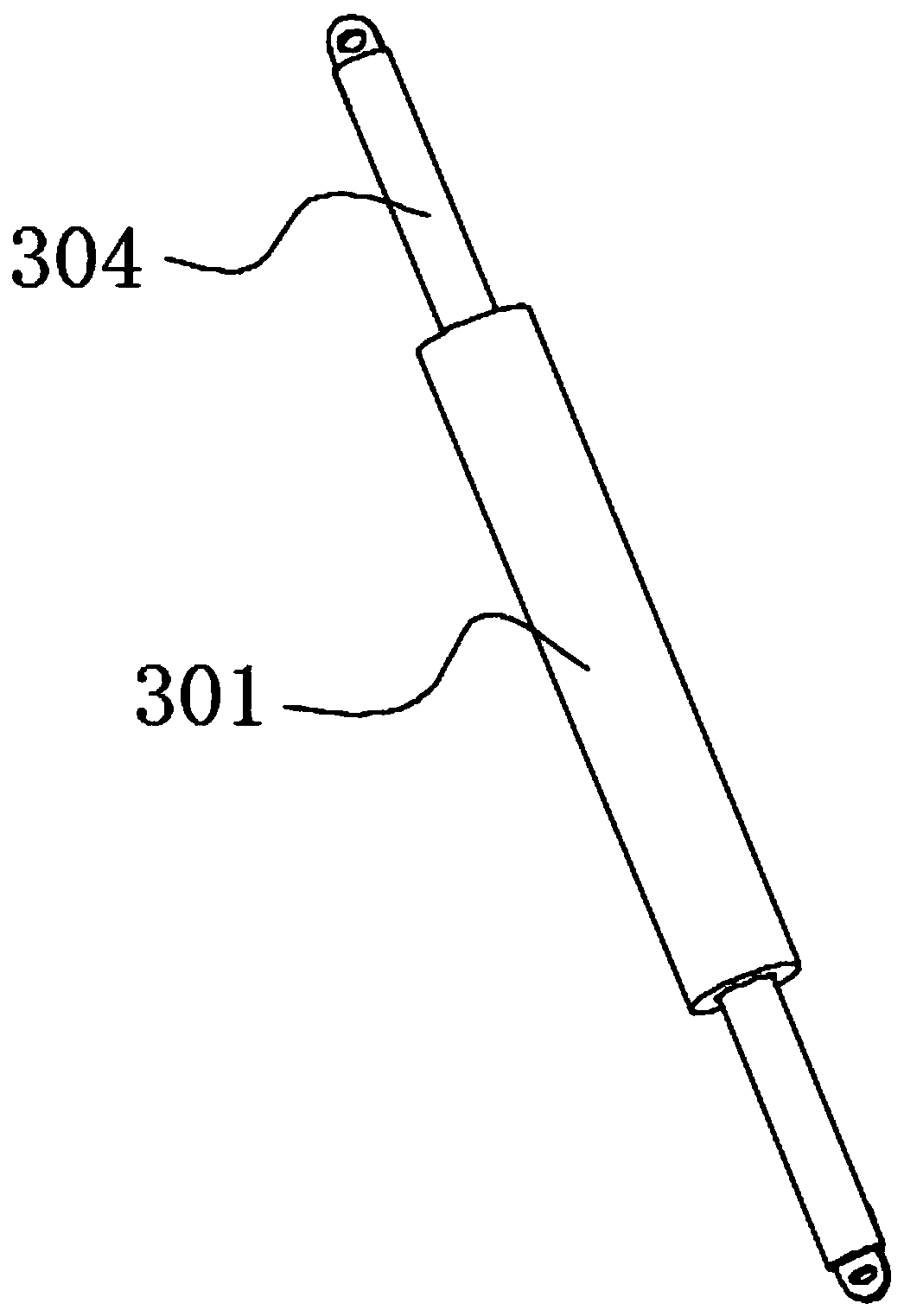

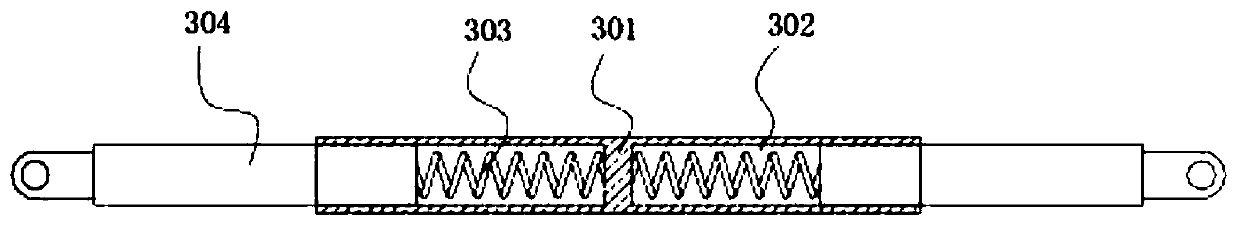

[0058] refer to Figure 1-10 , including a support ring body 1, a rotating support assembly 2 and an interval buffer assembly 3, a reinforcing support frame 5 is fixedly arranged in the middle of the support ring body 1, and an interval buffer assembly 3 is installed between two rotation support assemblies 2 through rotation pins , the interval buffer assembly 3 separates the adjacent rotating support assemblies 2 and performs windproof buffering and unloading force through elastic expansion and contraction.

[0059] The rotating support assembly 2 includes a rotating base, an elastic telescopic pole 201 and a holding hoop, the rotating base is rotatably mounted on the side wall of the support ring body 1, the holding hoop is fixedly arranged on the upper end of the elastic telescopic pole 201, and the rotating base is provided with a Screw hole 3 207 is arranged, and the lower end of elastic telescopic pole 201 is fixedly provided with bolt 205, and the lower end of elastic t...

Embodiment 2

[0068] refer to Figure 1-11 In this embodiment, the structural design of the support ring body 1 and the spacer buffer assembly 3 is the same as that of the first embodiment, except that the structure of the rotating support assembly 2 is different. In this embodiment, the rotating base includes a rotating shaft 206 and fixed ends at both ends. The connected limiting disc 208 and the rotating shaft 206 are rotatably mounted on the side wall of the supporting ring body 1 . In this embodiment, when the rotating support assembly 2 is assembled, the rotating shaft 206 is directly placed in the semi-arc rotating groove 101, and the locking member 4 is locked in the semi-arc through the screw through the first screw hole 102 and the second screw hole 405. At the position of the circular rotation groove 101, the semi-arc-shaped limiting groove 404 on the locking member 4 and the semi-arc-shaped rotating groove 101 on the support ring body 1 together form a complete annular limiting ...

Embodiment 3

[0070] refer to Figure 1-5 , 12 and 13, the structural design of the space buffer assembly 3 in this embodiment is the same as that of the rotating support assembly 2 in Embodiment 1, the difference is that the structure of the support ring 1 in this embodiment is different, in this embodiment, The outer wall of the supporting ring body 1 is equidistantly provided with integral rotating rings 103 , and the outer wall of the rotating ring 103 is provided with an arc-shaped notch 104 , and the rotating shaft 206 rotates in the arc-shaped notch 104 .

[0071] In this embodiment, the rotating shaft 206 is passed through the rotating ring 103, and then the bolt 205 at the lower end of the elastic telescopic strut 201 is passed through the arc-shaped notch 104 and screwed into the screw hole 3 207 on the rotating shaft 206, and at the same time the bolt is The perforation 209 on the 205 is located on the same straight line as the channel 211, and then the stop bar 212 is passed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com