Switching circuit for controlling clutch and brake of loom and working method of switching circuit

A switching circuit, clutch control technology, applied in general control systems, looms, program control and other directions, can solve the problems affecting the quality of weaving, can not be disconnected in time, slow starting speed, etc., to improve the efficiency of weaving, improve weaving. The effect of cloth quality and fast startup speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

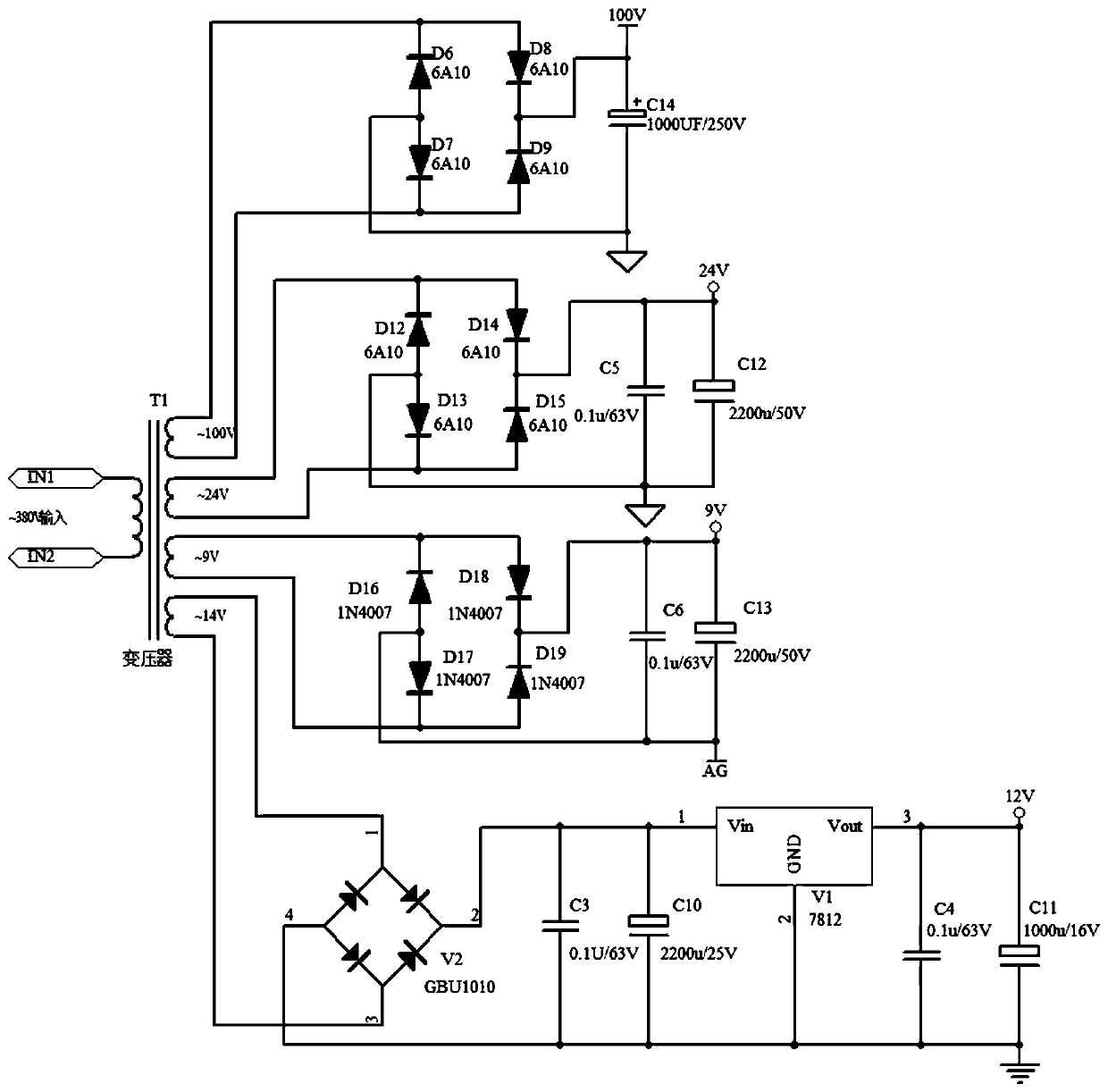

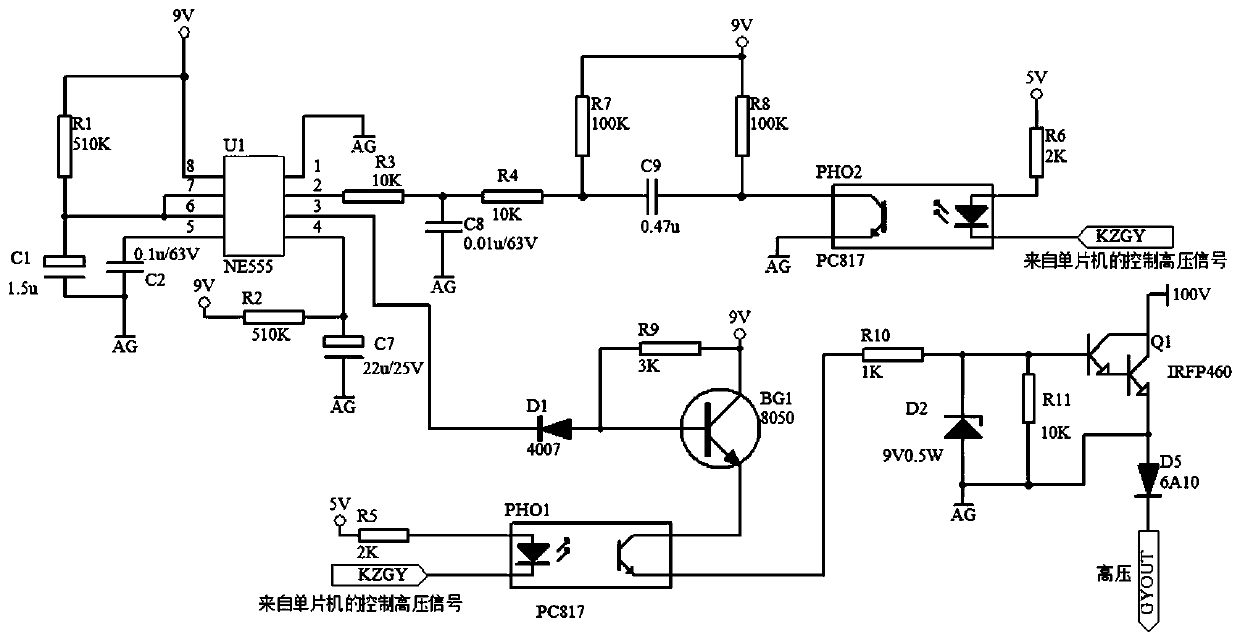

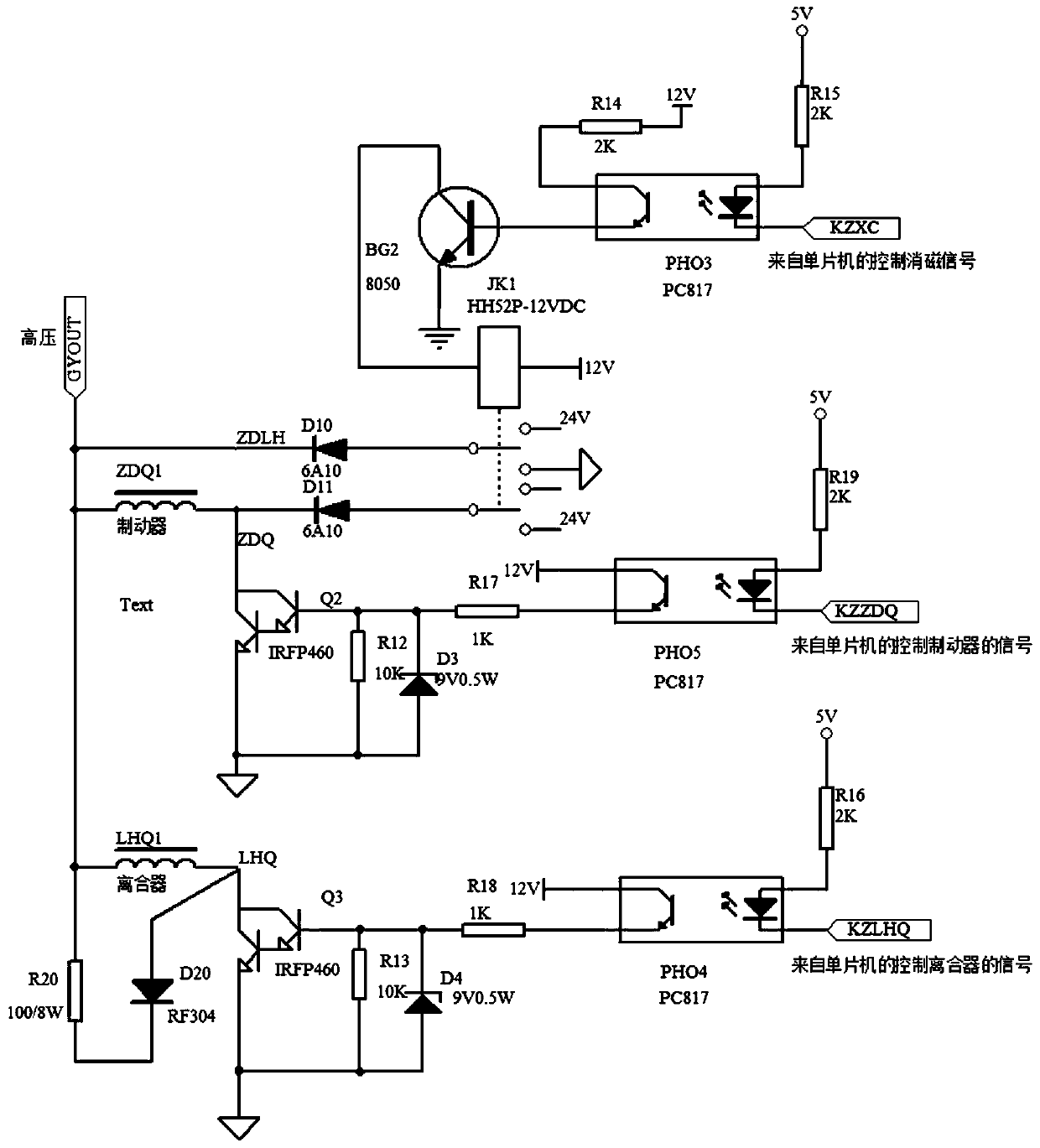

[0036] like figure 1 , figure 2 and image 3 As shown, a switching circuit for controlling the clutch and brake of the loom includes a power supply circuit, a high-voltage control circuit, a brake clutch control circuit and a single-chip microcomputer.

[0037] The power supply circuit includes a transformer, a plurality of rectification circuits, a plurality of filter circuits and a voltage stabilizing circuit; the primary winding end of the transformer is 380V alternating current, and the secondary winding end is respectively 100V alternating current, 24V alternating current, 9V alternating current, and 14V alternating current The multiple rectification circuits and filter circuits are respectively used to rectify and filter DC 100V, 24V, 9V and 12V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com