Apparatus and method for heating a device for exhaust gas after-treatment

A technology of exhaust post-treatment and heating method, which is applied in the direction of electric control of exhaust treatment device, diagnostic device of exhaust treatment device, exhaust device, etc., and can solve the problems of undisclosed targeted improvement of equipment and methods , to achieve the effect of reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

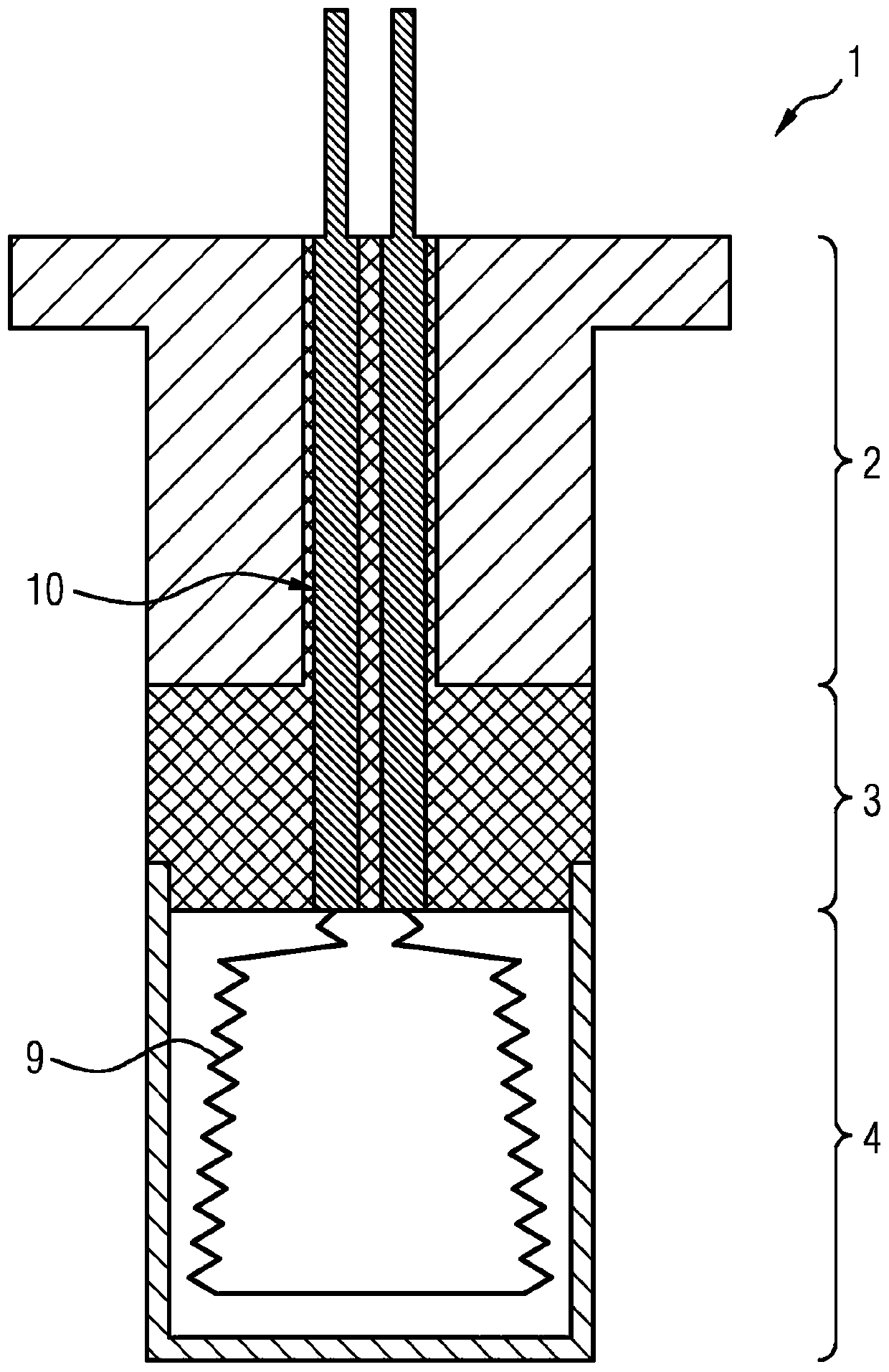

[0036] figure 1 A schematic sectional illustration through the heating element 1 is shown. The heating element 1 is divided into three zones. The "cold" end 2 forms the installation area of the heating element 1 . Via this region 2 the heating element 1 can be fastened to the shell of the honeycomb body and thus positioned in the hollow of the honeycomb body.

[0037] Below this zone, zone 3 represents the insulation zone, which creates thermal insulation between the heating zone 4 (to be described below) and the installation zone 2 . The heating zone 4 can also be referred to as a heating zone.

[0038] The entire heating element 1 is of pin-shaped design and can preferably be inserted into the honeycomb body in the radial direction. The insulating region 3 reduces the heat released by the heating element 1 towards the installation region 2 , so that at the same time the heat loss to the installation region 2 and thus to the outside of the honeycomb body is also reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com