Failure prediction system and failure prediction method

A fault prediction and fault technology, applied in prediction, non-redundancy-based fault handling, error detection/correction, etc., can solve problems such as deterioration of prediction accuracy, and achieve the effect of improving symptom detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

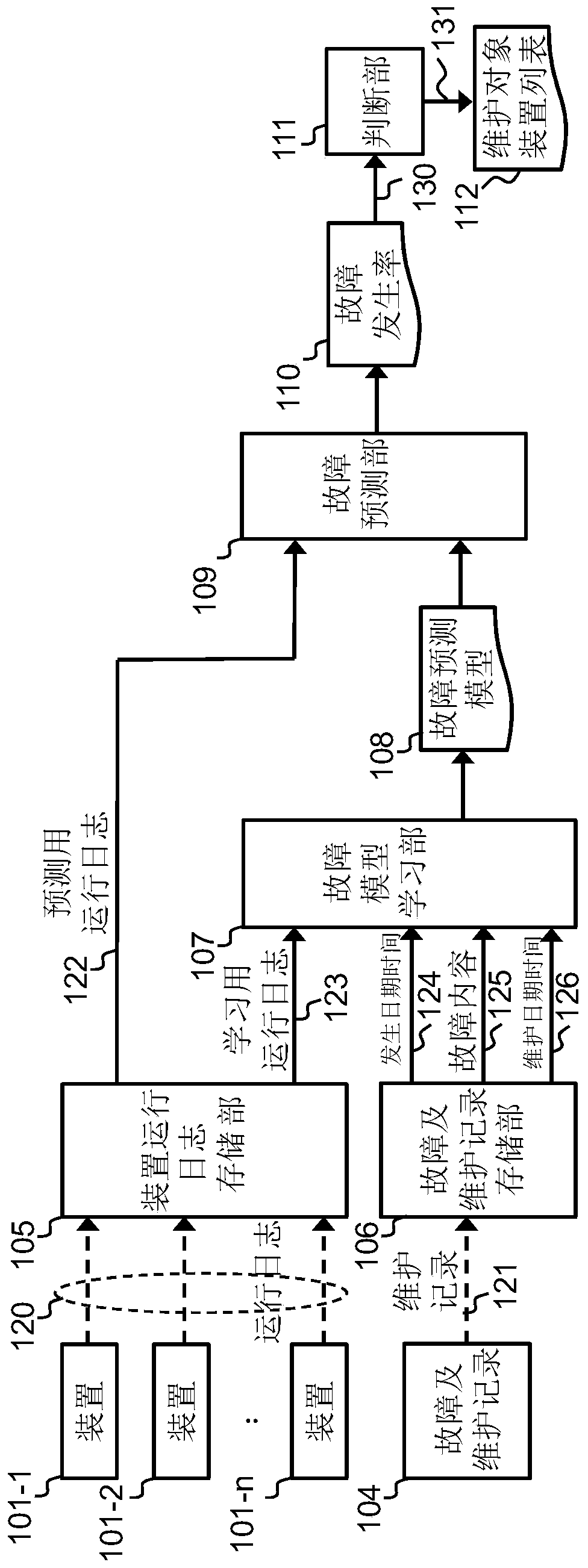

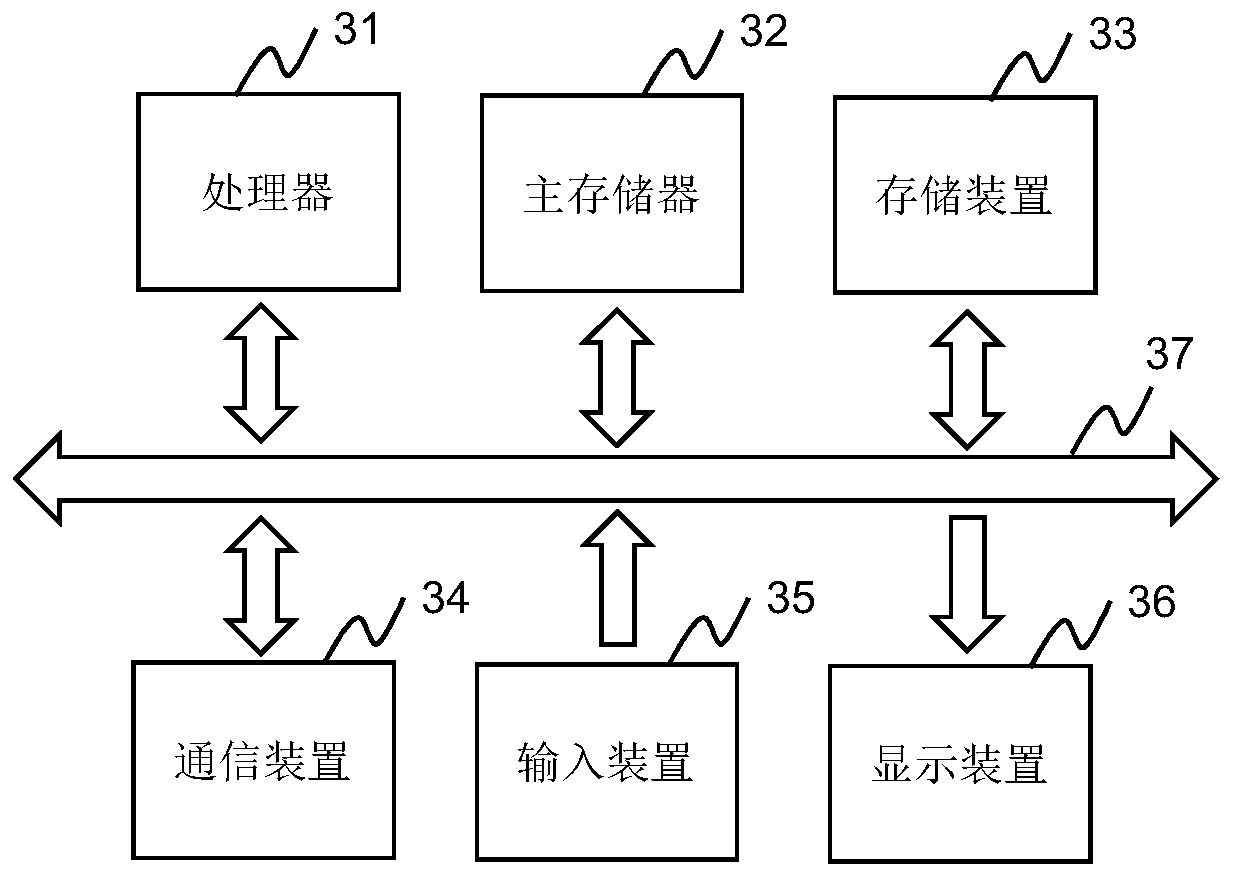

[0036] figure 1 It is a block diagram of the failure prediction system of this embodiment. figure 2 is the realization figure 1 A diagram of the hardware structure used in the fault prediction system shown.

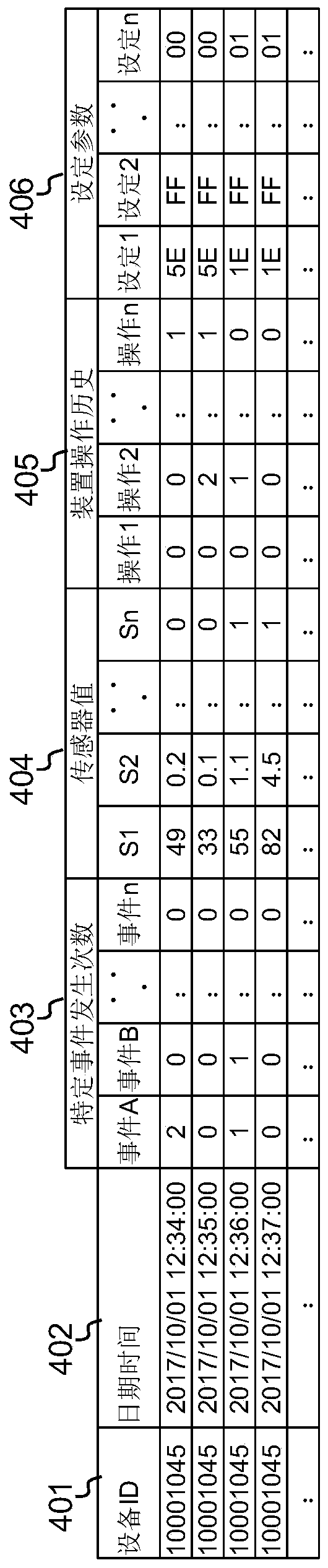

[0037] This method is as figure 1 As shown, machine learning is performed on the operation logs 120 collected from a plurality of devices 101-1 to 101-n as prediction target devices and the failure maintenance records 104 of the plurality of devices 101-1 to 101-n to generate a failure prediction The model includes a device log recording unit 105 , a failure maintenance record storage unit 106 , a failure model learning unit 107 , a failure prediction unit 109 and a judgment unit 111 . And, by inputting the generated failure prediction model into the device operation log, the occurrence rate of failure is predicted and the threshold value judgment is performed, thereby judging the failure risk of the devices 101-1 to 101-n.

[0038] The fault prediction system consti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com