Preparation process of zanthoxylum armatum marinating oil

A manufacturing process and a technology of pepper brine oil, which is applied in the field of manufacturing technology of vine pepper brine oil, can solve the problems of poor taste of brine products, poor taste of brine, and reduced aroma, and achieves rich aroma, rich and mellow taste, and simple processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

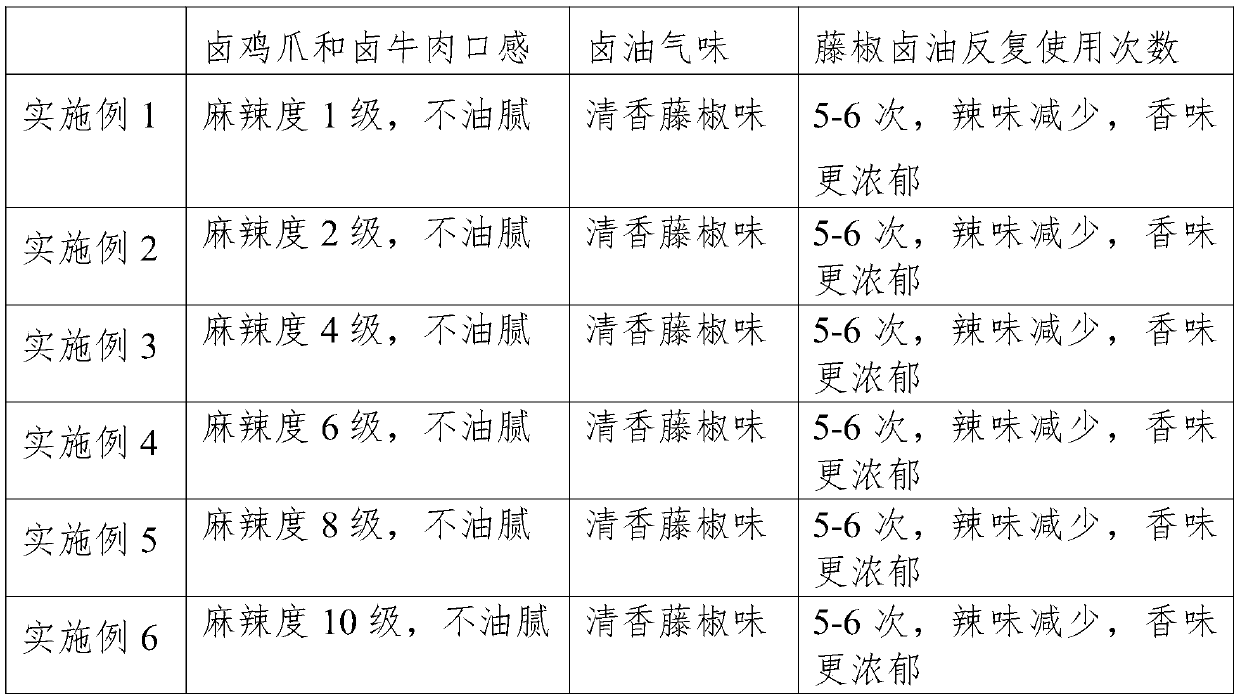

Examples

Embodiment 2

[0035] A kind of manufacturing process of rattan pepper bittern oil of this embodiment, comprises the following steps:

[0036] S1. First, add rapeseed oil to the oil pan and heat it. When it is heated to 123°C, add ginger, garlic, onion, green onion, glutinous rice cake pepper, Pixian watercress, spices, dried rattan pepper, and seasoning in turn for frying; Steps to join:

[0037] Add ginger and fry for 3 minutes;

[0038] Then add garlic and continue frying for 1min;

[0039] Add onions and scallions and fry for 3 minutes;

[0040] Then add glutinous rice cake chili and fry for 1.2 hours;

[0041] After the deep-frying time of glutinous rice cake chili is up, then add Pixian Douban and deep-fry for 25 minutes;

[0042] After the frying time of Pixian Douban is up, add spices and fry for 27 minutes;

[0043] After the spice frying time is up, add dried rattan pepper and seasonings and continue frying for 15 minutes;

[0044] S2. Then filter out the raw material slag in...

Embodiment 3

[0048] A kind of manufacturing process of rattan pepper bittern oil of this embodiment, comprises the following steps:

[0049] S1. First, add rapeseed oil to the oil pan and heat it. When it is heated to 125°C, add ginger, garlic, onion, green onion, glutinous rice cake pepper, Pixian watercress, spices, dried rattan pepper, and seasoning in turn for frying; Steps to join:

[0050] Add ginger and fry for 3 minutes;

[0051] Then add garlic and continue frying for 1min;

[0052] Add onions and scallions and fry for 3 minutes;

[0053] Then add glutinous rice cake chili and fry for 1.5 hours;

[0054]After the deep-frying time of glutinous rice cake chili is up, then add Pixian Douban and deep-fry for 30 minutes;

[0055] After the frying time of Pixian Douban is up, add spices and fry for 30 minutes;

[0056] After the spice frying time is up, add dried rattan pepper and seasonings and continue frying for 15 minutes;

[0057] S2. Then filter out the raw material slag in ...

Embodiment 4

[0061] A kind of manufacturing process of rattan pepper bittern oil of this embodiment, comprises the following steps:

[0062] S1. First, add rapeseed oil into the oil pan and heat it. When it is heated to 121°C, add ginger, garlic, onion, green onion, glutinous rice cake pepper, Pixian watercress, spices, dried rattan pepper, and seasoning in turn for frying; Steps to join:

[0063] Add ginger and fry for 3 minutes;

[0064] Then add garlic and continue frying for 1 minute;

[0065] Add onions and scallions and fry for 3 minutes;

[0066] Then add glutinous rice cake chili and fry for 1.1h;

[0067] After the deep-frying time of glutinous rice cake chili is up, then add Pixian Douban and deep-fry for 22 minutes;

[0068] After the frying time of Pixian Douban is up, add spices and fry for 26 minutes;

[0069] After the spice frying time is up, add dried rattan pepper and seasonings and continue frying for 15 minutes;

[0070] S2. Then filter out the raw material slag i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com