Gluing equipment for bonding auto parts

An auto parts and bonding technology, applied in the field of gluing, can solve the problems of inaccurate gluing position, lower gluing quality, and affect the use effect, etc., and achieve the effect of accurate gluing position, convenient vertical adjustment, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

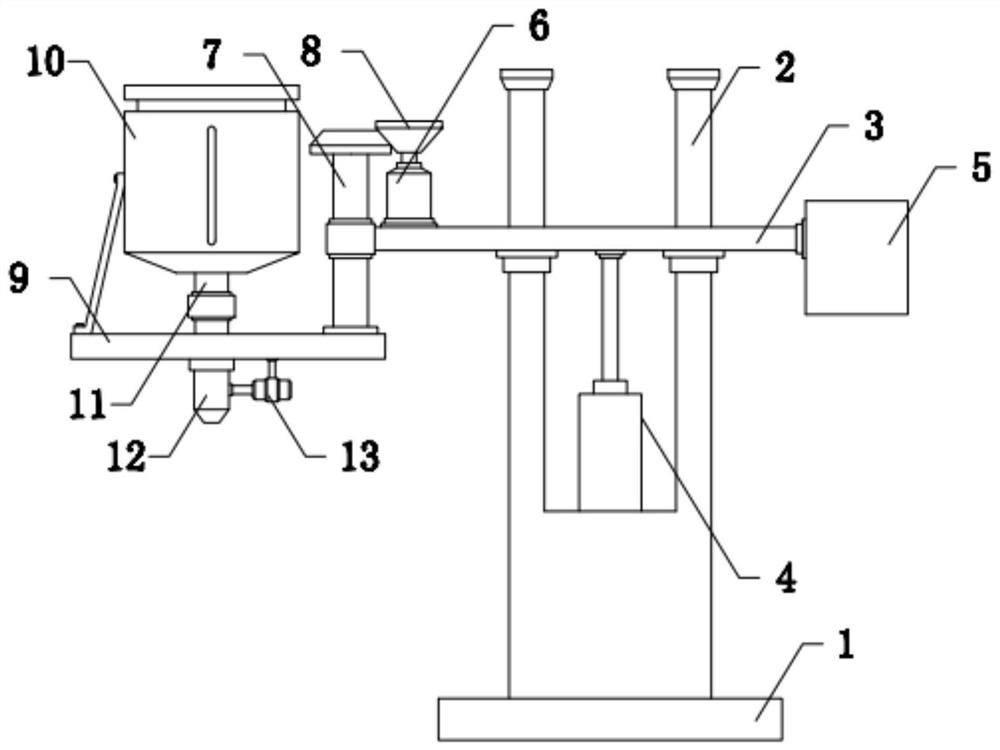

[0022] see Figure 1-2 , the present invention provides a technical solution: a kind of gluing equipment for auto parts bonding, comprising a base 1, the upper end of the base 1 is connected with a slide bar 2, and the upper side of the outer wall of the slide bar 2 is sleeved with an upper support plate 3, The middle part of the upper surface of the base 1 is provided with a lifting cylinder 4, and the top end of the telescopic rod of the lifting cylinder 4 is connected to the lower surface of the upper support plate 3;

[0023] The lifting cylinder 4 is used as the power mechanism for the longitudinal movement of the upper support plate 3. The lifting cylinder 4 drives the upper support plate 3 to rise or fall. 3 play a supporting role;

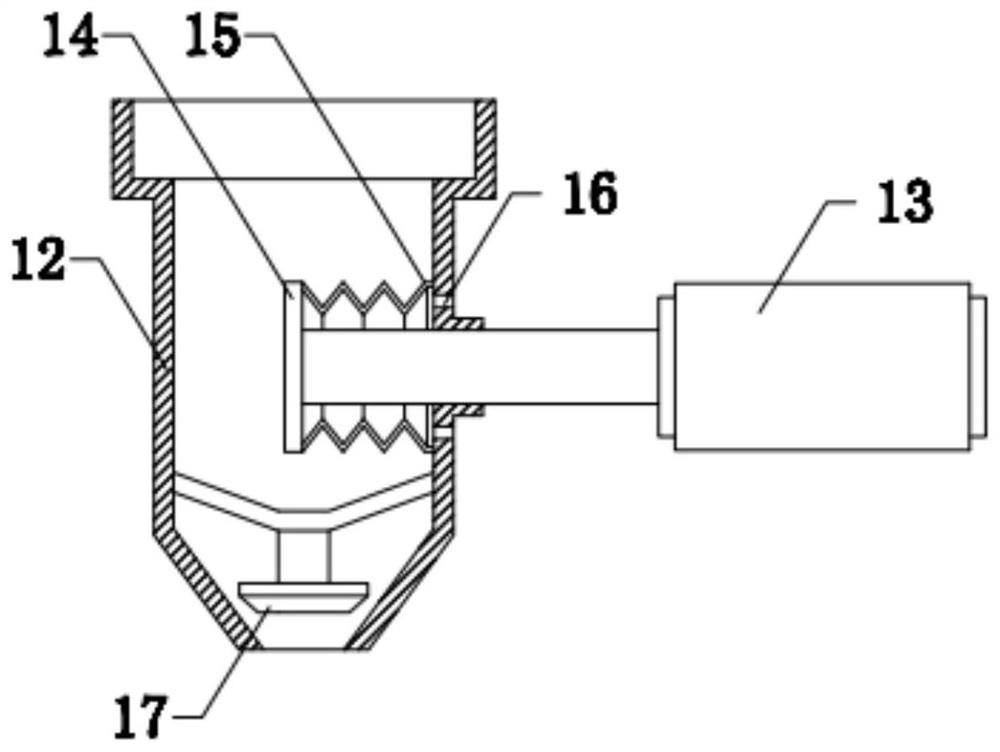

[0024] The left end of the upper surface of the upper support plate 3 is equipped with a driving motor 6 through the motor base, and the left end of the upper support plate 3 is connected with a rotating shaft 7 through a bearing, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com