O-ring continuous supply device

A technology of O-shaped sealing ring and supply device, which is applied in assembly machines, metal processing equipment, metal processing, etc., and can solve problems such as deformation, only women with slender fingers are competent, and operators' fingers are worn out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

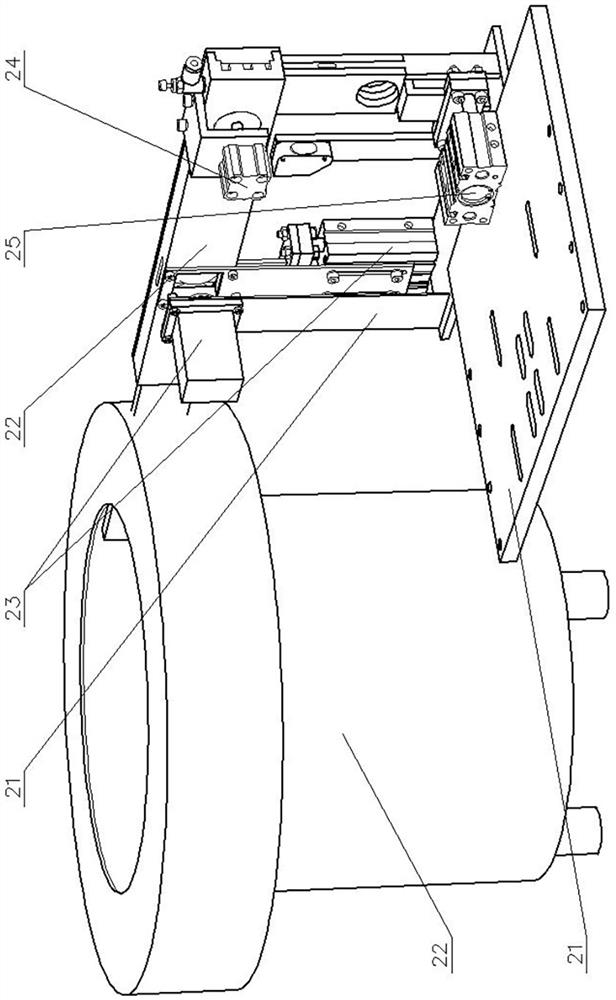

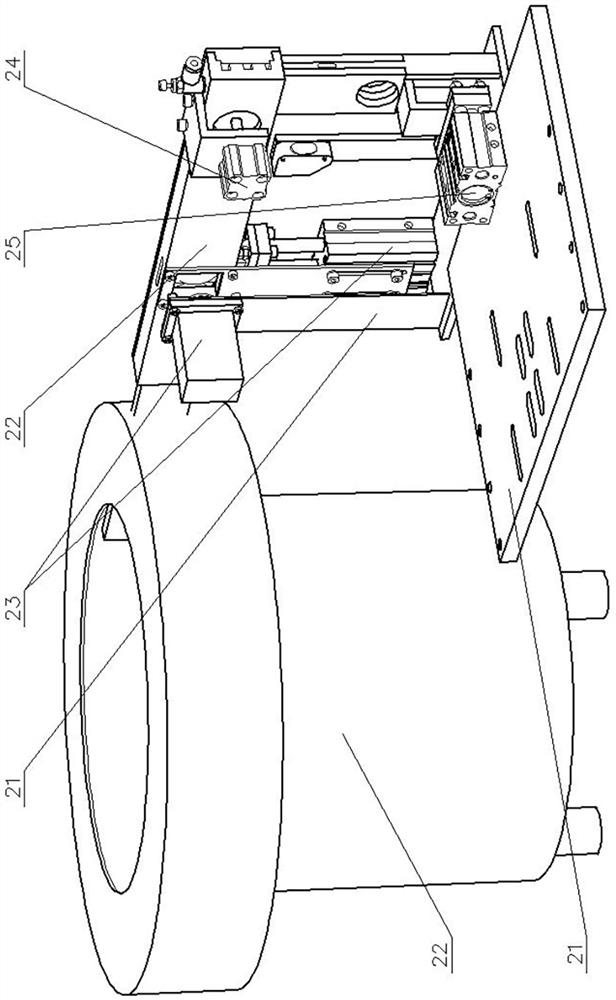

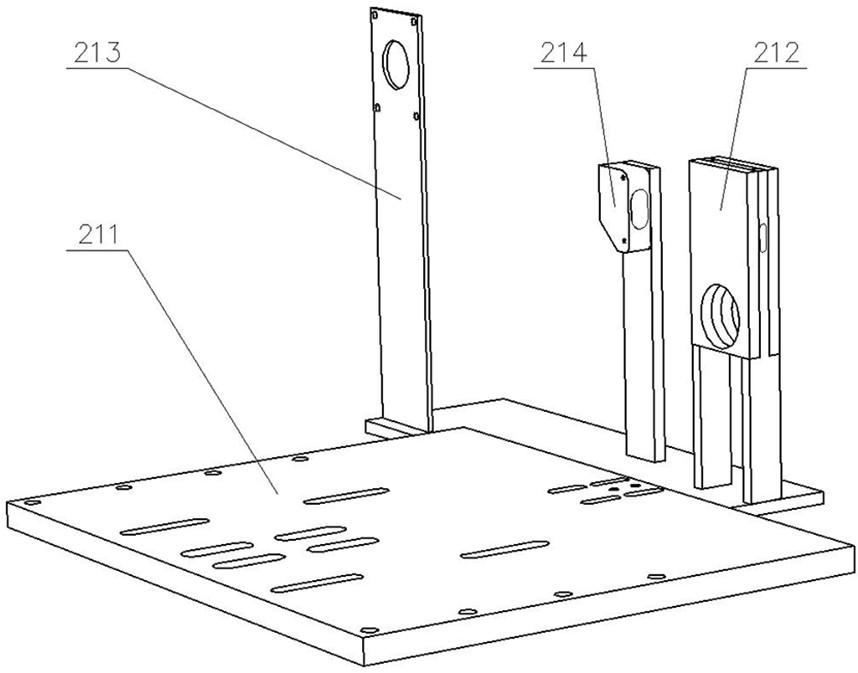

[0023] 2. O-ring continuous supply device 21, supply rack 211, partition 212, vertical channel 213, camera leg 214, photoelectric switch 22, feeding device 221, feeding tray 222, transverse channel 223, compressed air connector 224 , window 23, sorting device 231, sorting cylinder 232, sorting plate 233, camera 24, clamping cylinder 241, clamping cylinder body 242, clamping rod 243, pressure plate 25, bracket cylinder 251, bracket cylinder body 252, bracket bar 253, supporting plate.

[0024] exist Figure 1-Figure 7 In the shown embodiment: the dividing plate 211 arranged horizontally in the supply rack of the O-ring continuous supply device 2 is in the shape of a rectangular flat plate, and the vertical channel 212 in the shape of a rectangular flat plate is along the center of the section perpendicular to the length direction along the vertical channel 212. The length direction is provided with a through hole with a rectangular cross-section, and the long side of the recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com