Self-propelled door-shaped automatic spraying maintenance device

A technology of automatic spraying and spraying devices, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult control of maintenance quality, poor construction convenience, low material utilization rate, etc., to achieve guaranteed time, flexible use, and raw materials The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0019] The problem to be solved by the present invention is to provide a self-propelled door type that can solve the disadvantages of difficult maintenance, difficult control of maintenance quality, large manual workload, poor construction convenience, poor maintenance effect, and low material utilization rate in the maintenance construction of prefabricated beams. Automatic sprinkler maintenance device.

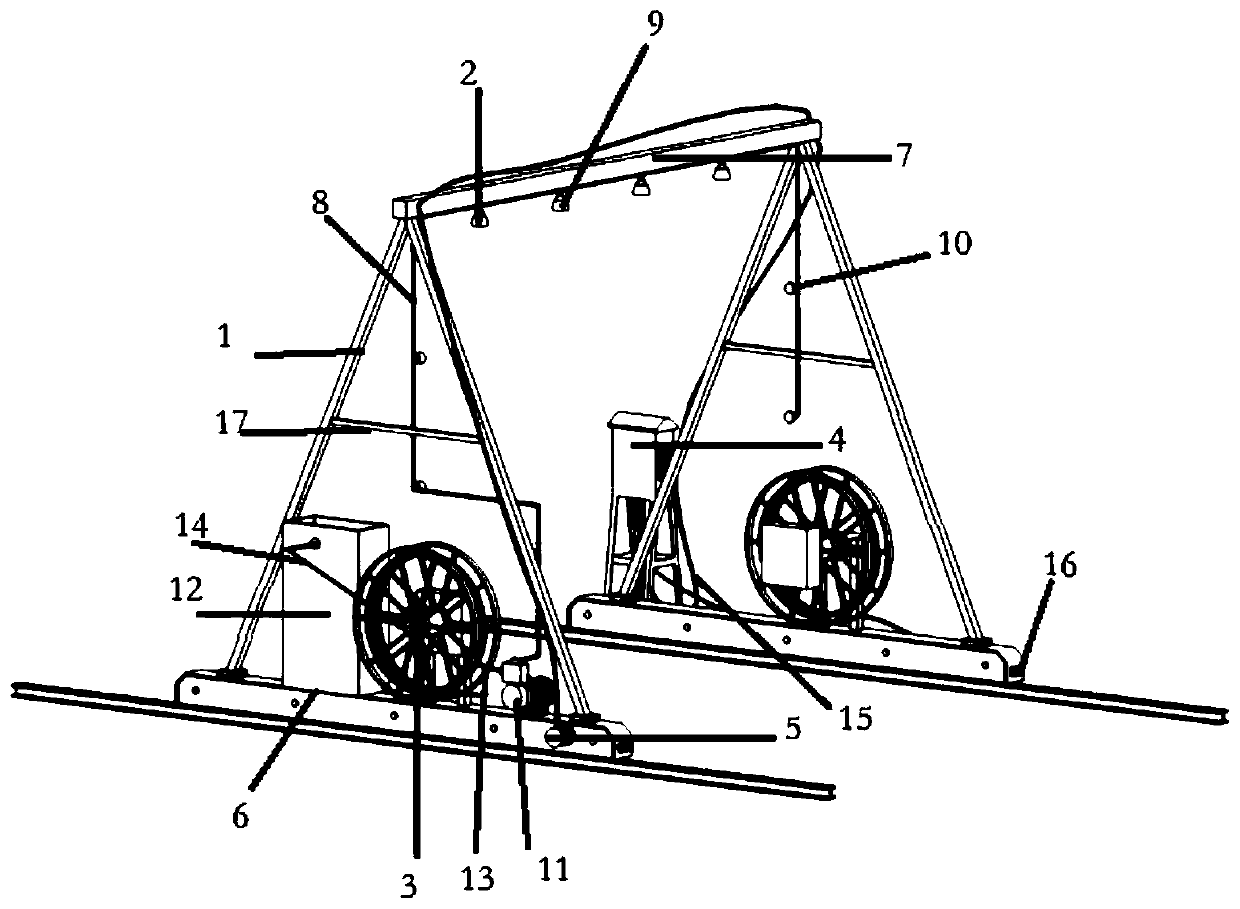

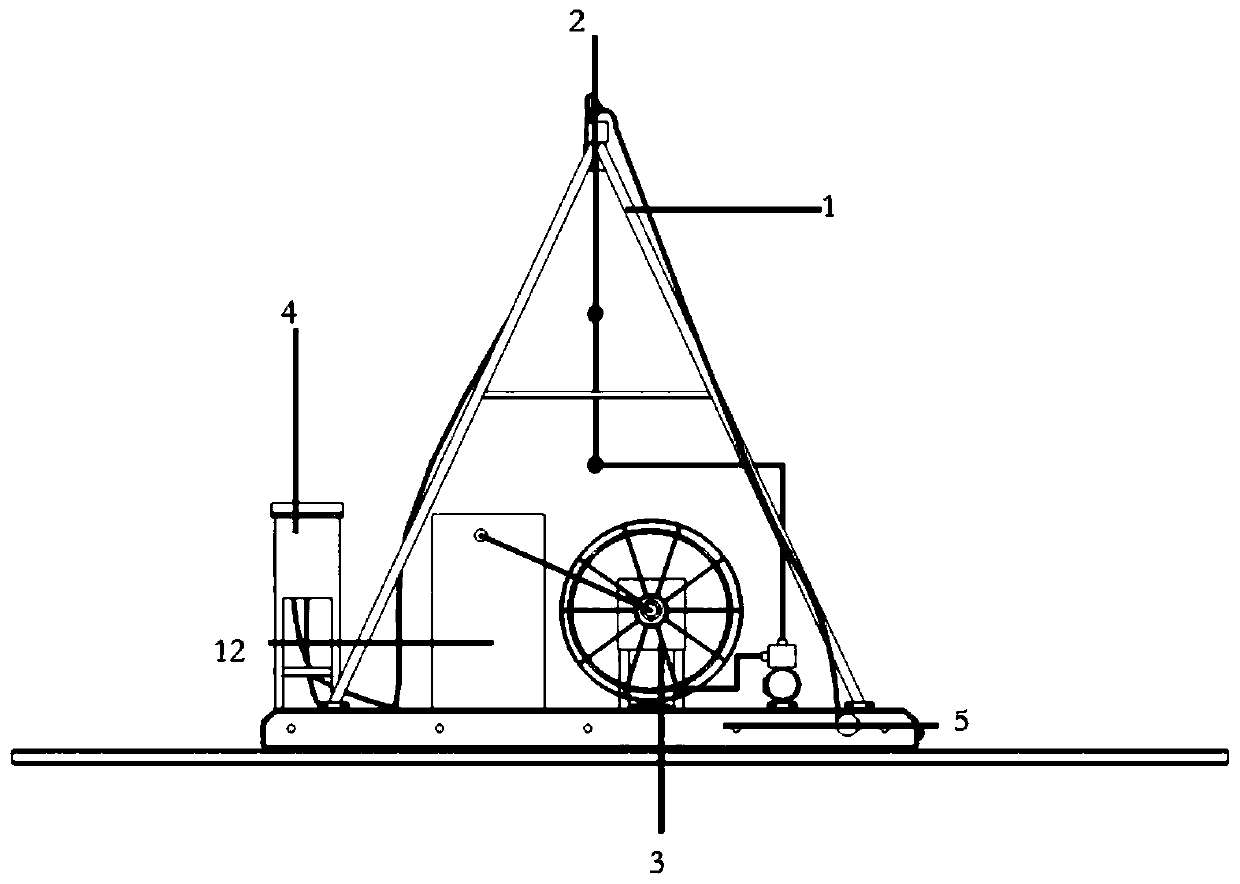

[0020] Such as figure 1 , figure 2 As shown, in order to ensure stable work and high work efficiency during use, the present invention relates to a self-propelled door-type automatic spray maintenance device, including: a fixed frame 1, a spray device 2, and a retractable device 3 , circuit control box 4, mobile device 5;

[0021] The fixed frame 1 is triangular; the mobile device 5 is provided with a base 6; the lower end of the fixed frame 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com