Intelligent dustbin

A trash can and garbage technology, applied in the direction of trash cans, garbage collection, household appliances, etc., can solve the problems of reduced work efficiency, poor user experience, effective feedback of internal capacity, etc., to improve detection accuracy and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

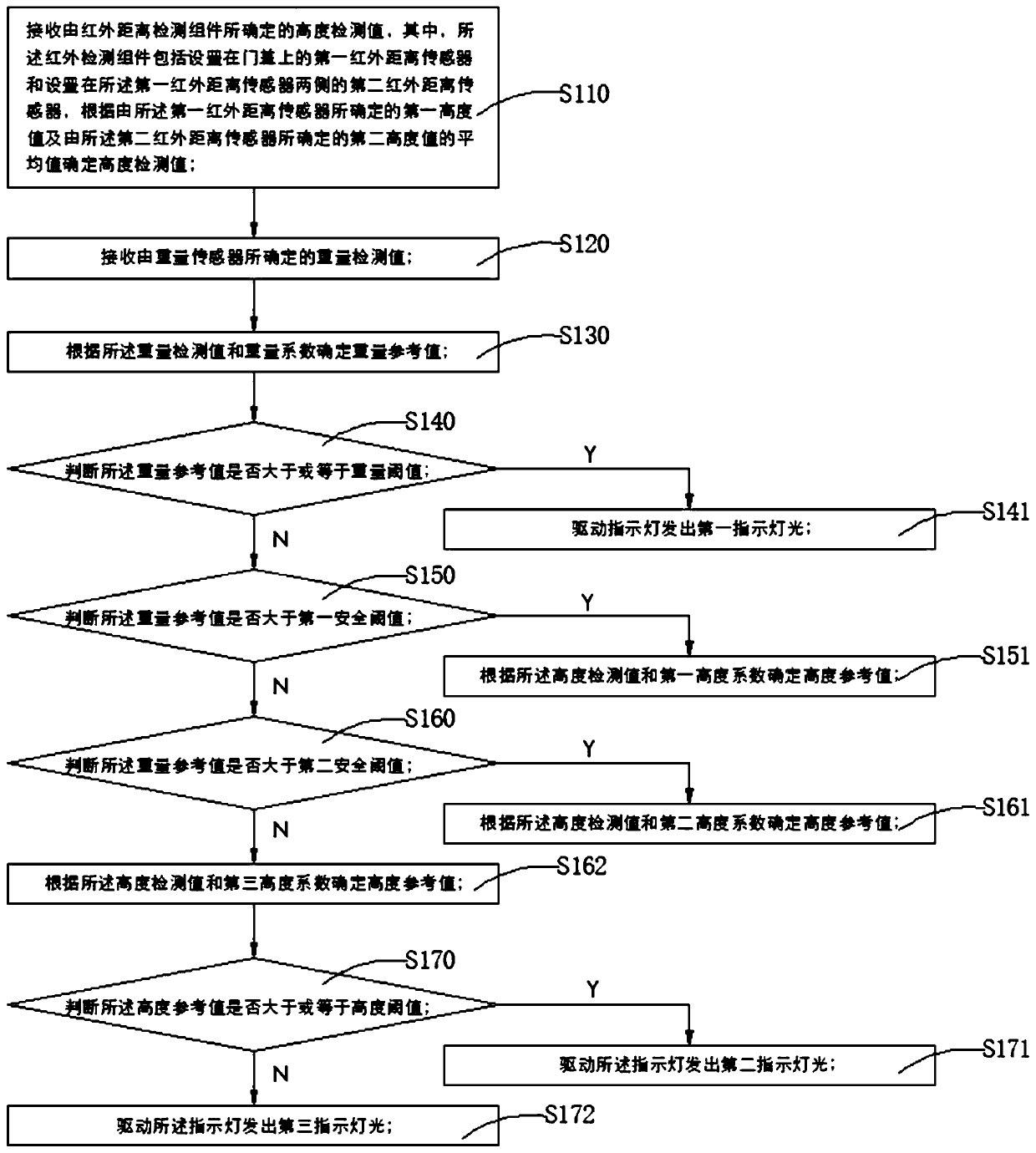

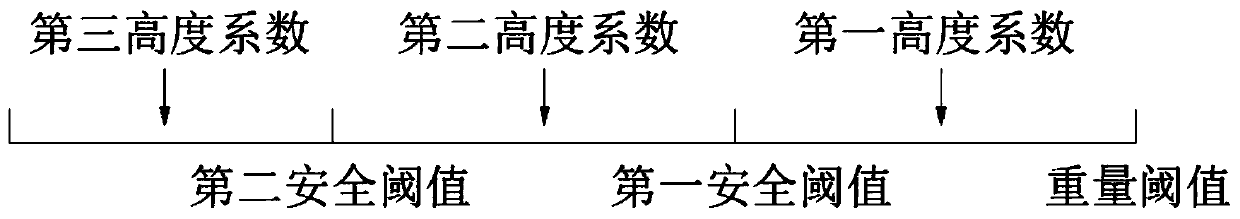

[0029] Please refer to Figures 1 and 2, the application of the present invention provides a garbage disposal control method for smart trash cans, which includes:

[0030] S110: Receive the height detection value determined by the infrared distance detection component, the infrared detection component includes a first infrared distance sensor 31 arranged on the door cover 20 and a second infrared distance sensor 32 arranged on both sides of the first infrared distance sensor 31 , determine the height detection value according to the average value of the first height value determined by the first infrared distance sensor 31 and the second height value determined by the second infrared distance sensor 32 .

[0031] Wherein, the first infrared sensor and the second infrared sensor are respectively used to detect the vertical height distance from the top of the garbage in the trash can to the first infrared sensor and the second infrared sensor. Specifically, the first infrared sen...

Embodiment 2

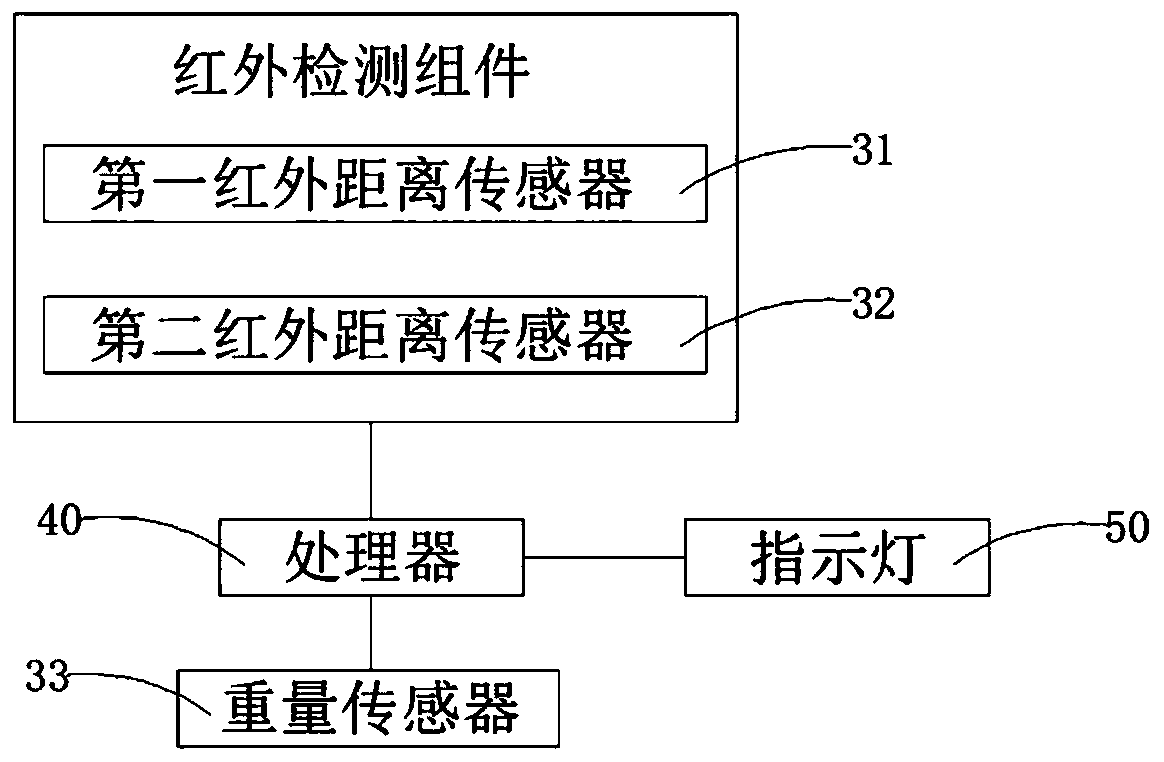

[0051] Please refer to figure 2 and 3 As shown, the application of the present invention is also a trash can, which includes: a bucket body 10 , a door cover 20 , an infrared detection component, a weight sensor 33 , a processor 40 and an indicator light 50 .

[0052] The door cover 20 is hingedly connected with the barrel body 10, and the infrared detection assembly is arranged on the door cover 20. The infrared detection assembly includes a first infrared distance sensor 31 and a second infrared distance sensor 32, and the second infrared distance sensor 32 is arranged at the first infrared distance sensor. On both sides of the sensor 31 , the processor 40 determines the height detection value according to the average value of the first height value determined by the first infrared distance sensor 31 and the second height value determined by the second infrared distance sensor 32 .

[0053] The weight sensor 33 is arranged at the bottom of the bucket body 10, and the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com