Loading and unloading device used for automatic wharf container

A technology of automated docks and loading and unloading devices, applied in storage devices, safety devices, loading/unloading, etc., can solve problems such as safety hazards, container fixing, container dumping, etc., to prevent safety hazards, prevent sliding and falling, and prevent shaking and dumping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

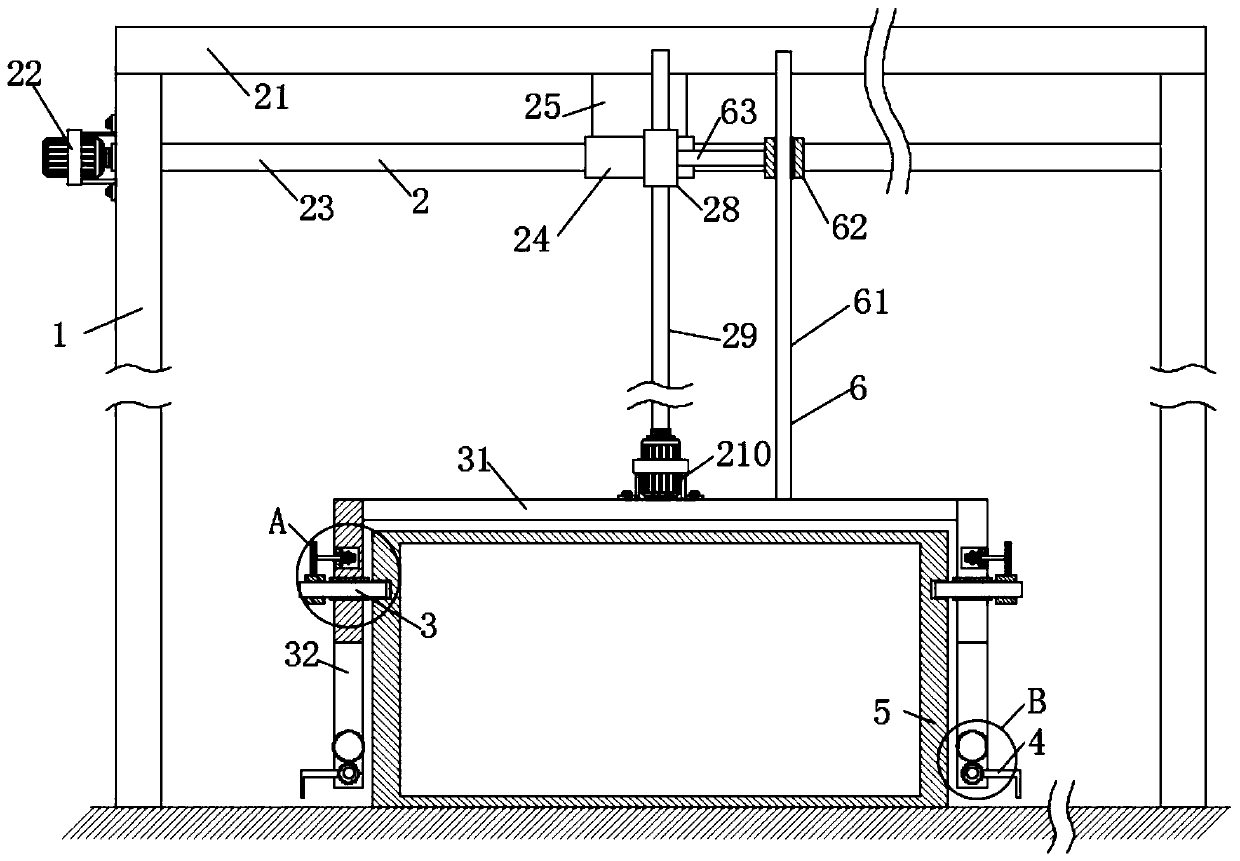

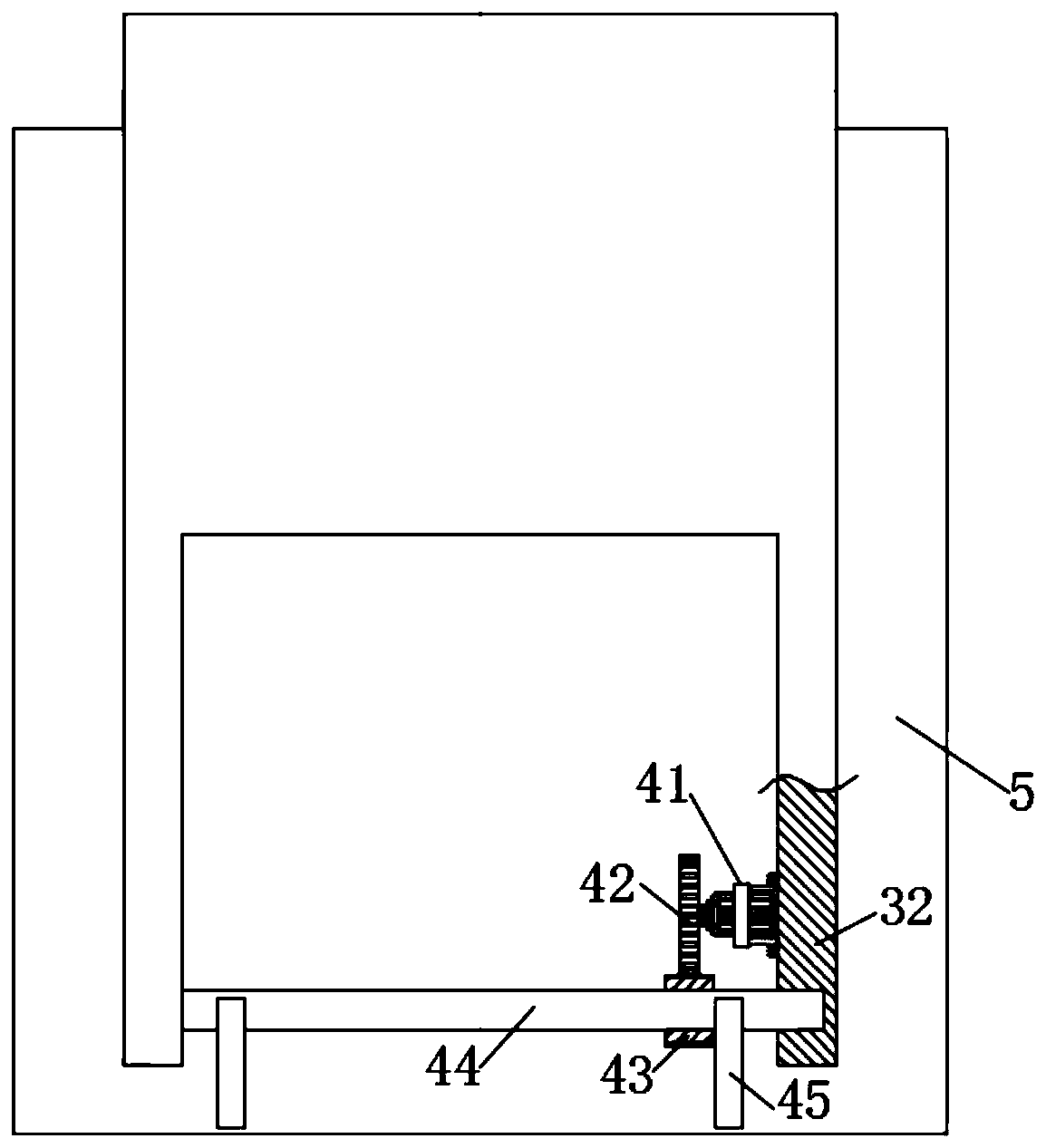

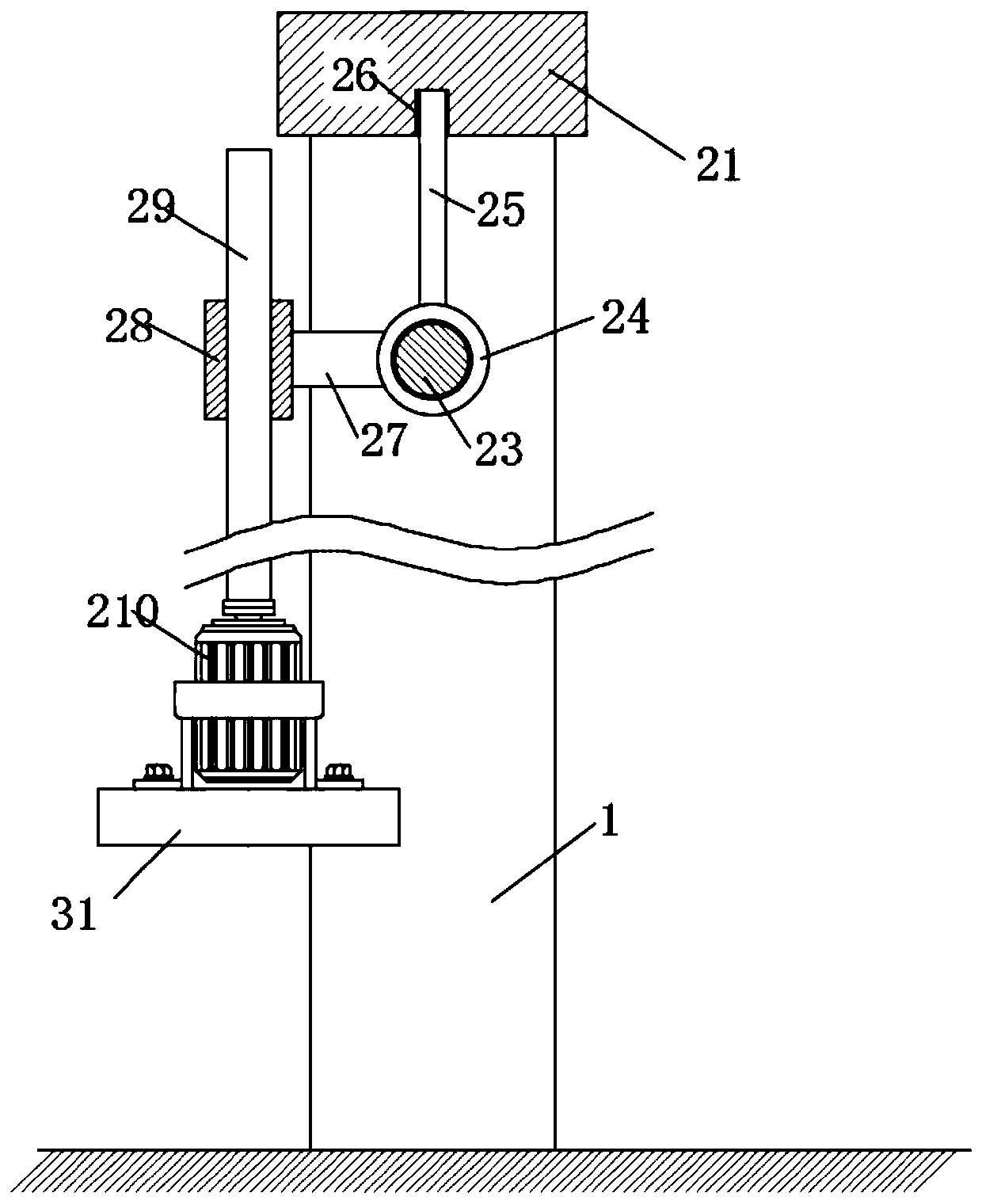

[0024] Example: such as Figure 1-5 As shown, the present invention is a loading and unloading device for automated terminal containers, including support columns 1, the top of the two support columns 1 is equipped with the same handling mechanism 2, the lower end of the handling mechanism 2 is equipped with a fixing mechanism 3, the fixing mechanism 3 A container 5 is arranged inside the container, and a stabilizing mechanism 4 is installed at the lower end of the fixing mechanism 3 .

[0025] The transport mechanism 2 comprises a top plate 21, a first motor 22, a first threaded rod 23, a first threaded cylinder 24, a clamping plate 25, a chute 26, a connecting plate 27, a second threaded cylinder 28, a second threaded rod 29, a second Motor 210, both sides of the lower surface of the top plate 21 are respectively fixedly connected to the tops of the two support columns 1, one side of the outer wall of the support column 1 is fixedly connected with the first motor 22, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com