Heat insulation cover of kitchen range

A technology for heat shields and cookers, which is applied in the directions of household stoves, household heating, heating fuels, etc., can solve the problems such as the temperature rise of the first panel, the inability to replenish secondary air in time, and the low efficiency of the cooker, so as to improve the combustion efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

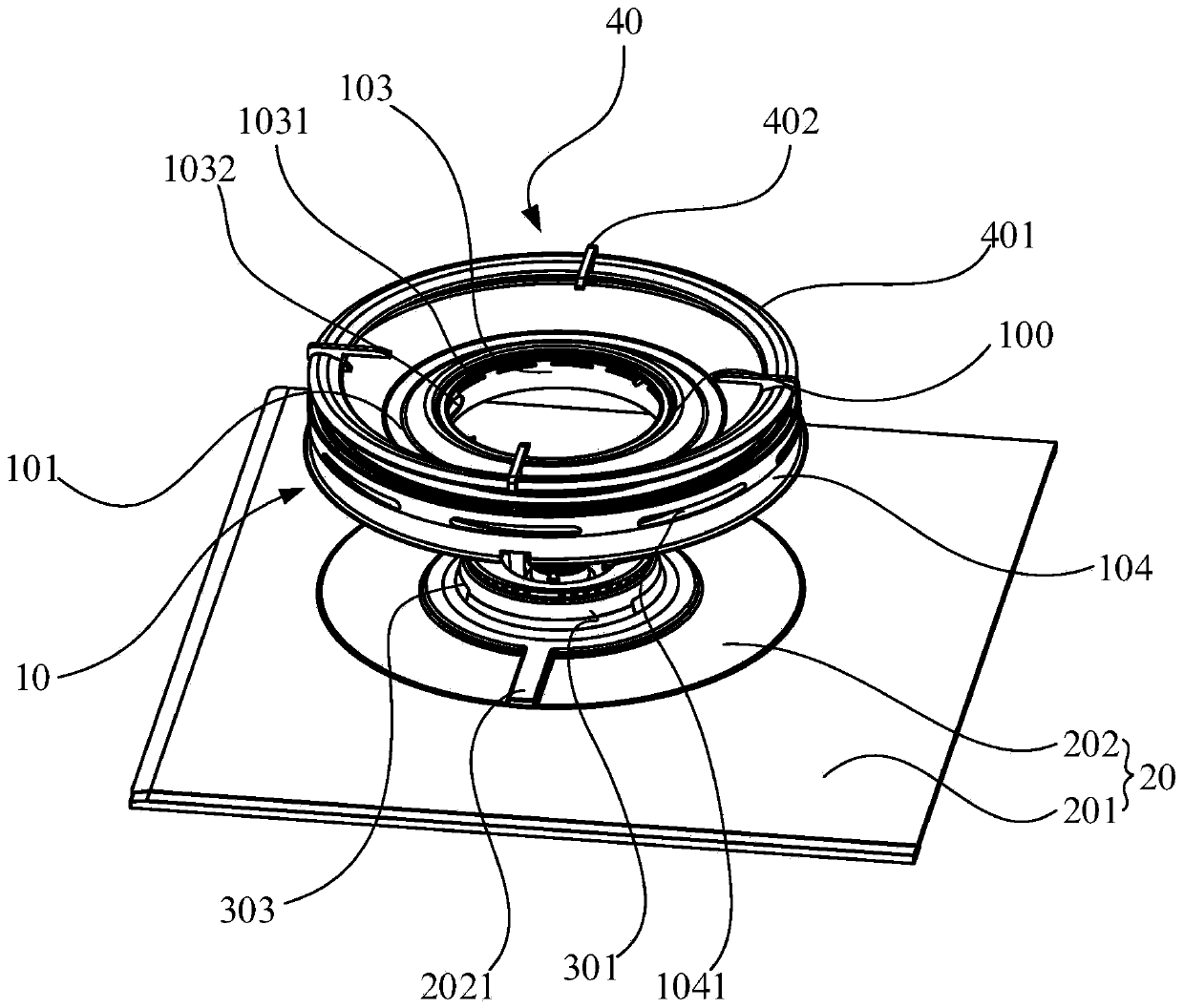

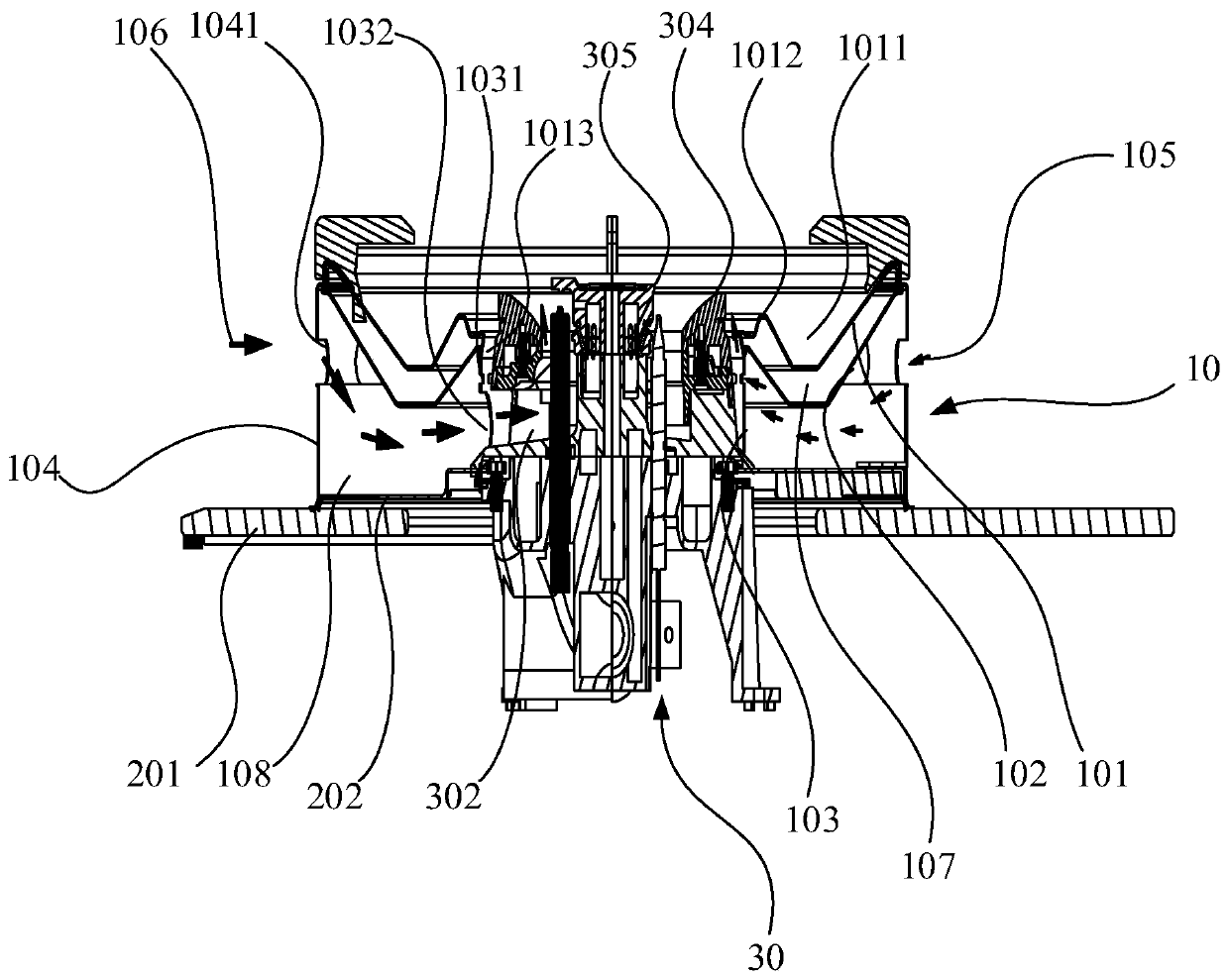

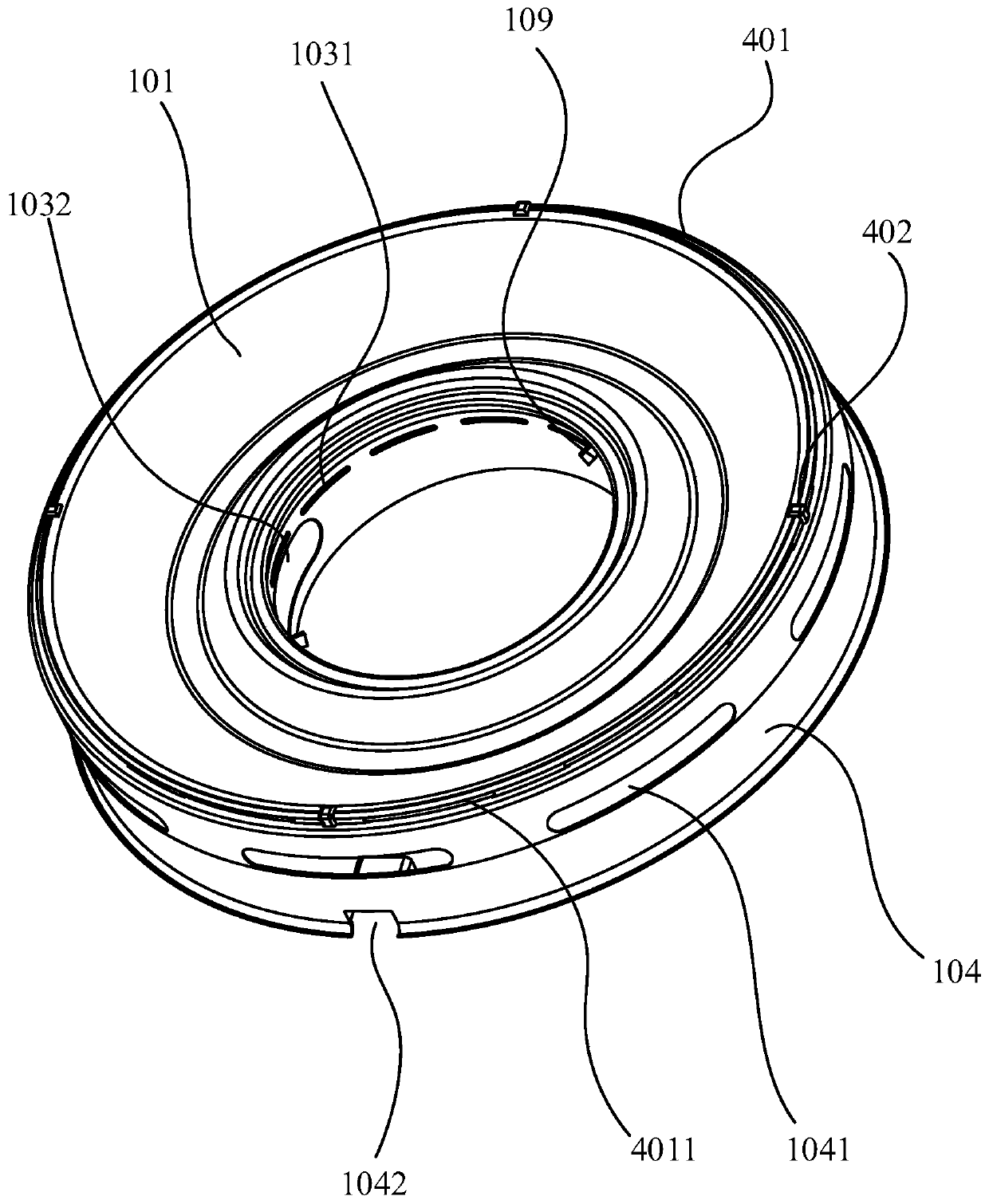

[0089] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a heat shield for a cooker, which includes a heat shield body 10 , and the heat shield body 10 is ring-shaped as a whole. The heat shield body 10 is sleeved on the outside of the burner 30, and the heat shield body 10 and the burner 30 are arranged at intervals, so that the contact between the heat shield and the burner 30 can be avoided, and the heat generated by the burner 30 can be prevented from directly acting on the heat shield. Place on heat cover. The bottom of the heat shield body 10 is detachably connected to the panel 20. The heat shield body 10 includes a first passage 105 and a second passage 106. The first passage 105 passes through the gap ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap