Fingerprint chip module preparation method, fingerprint chip module and electronic device

A fingerprint chip and module technology, applied in circuits, electrical components, electrical solid-state devices, etc., can solve the problems of complex structural design of finished products, increased cost and production difficulty, and reduced product yield, etc., to achieve simple structure and improved yield. , the effect of increasing the conductive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

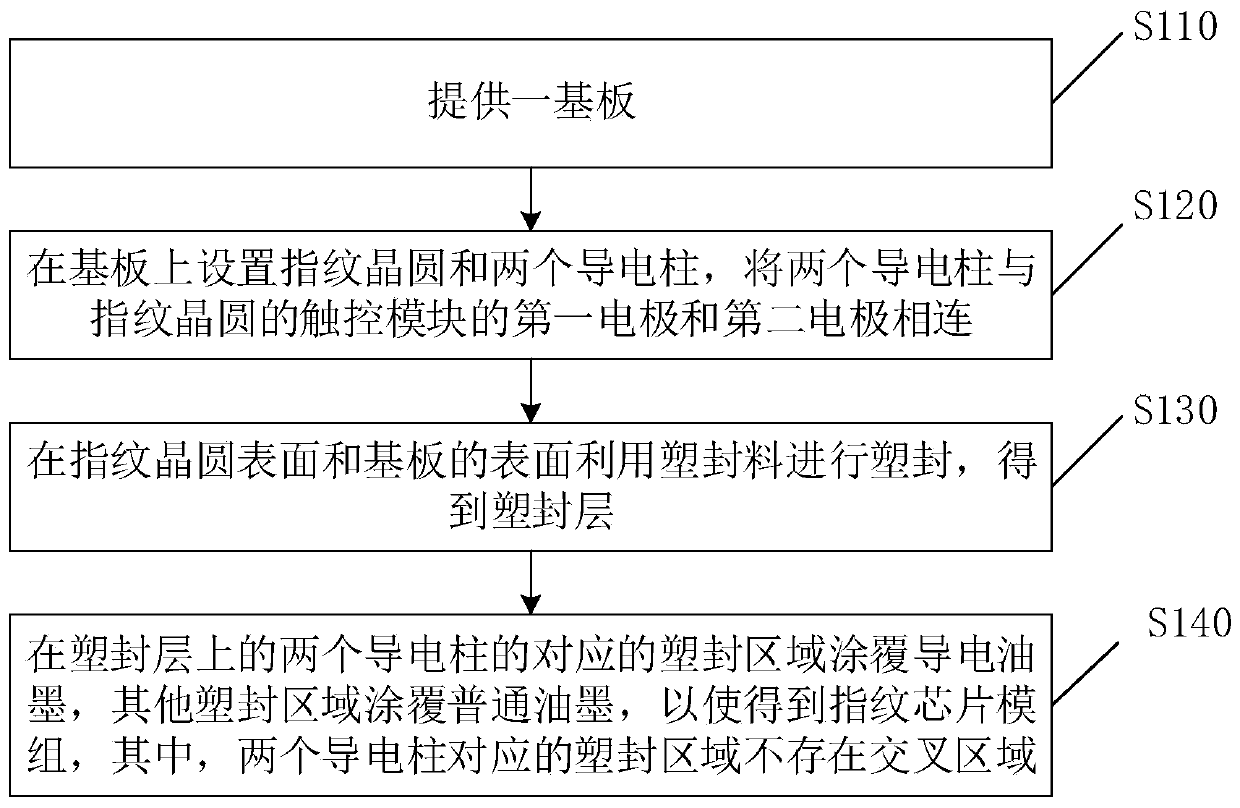

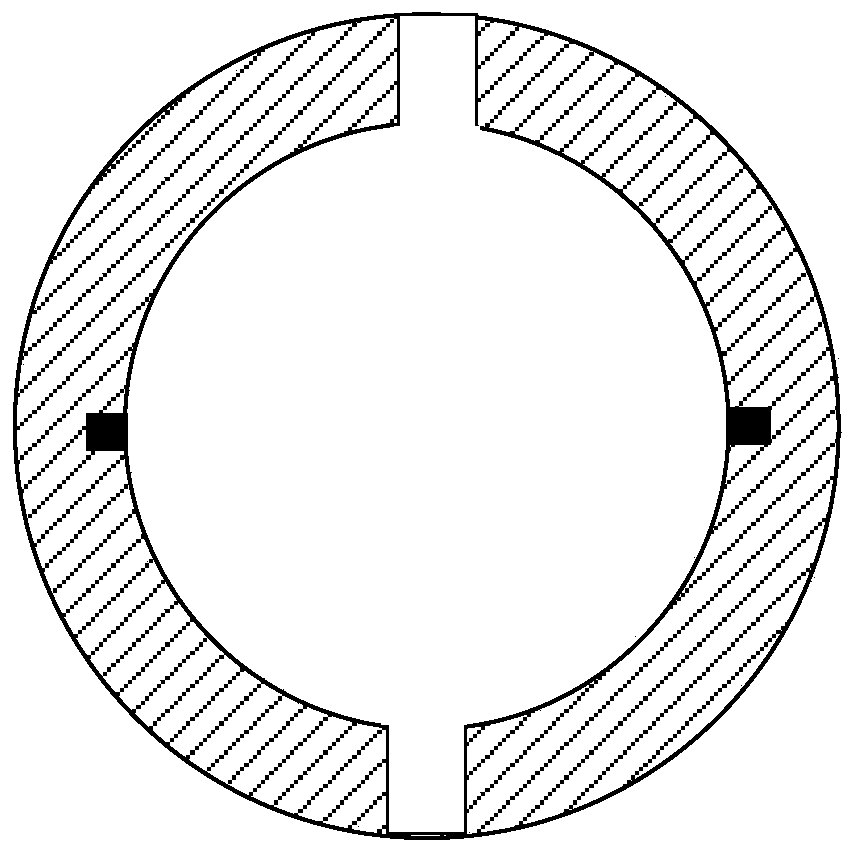

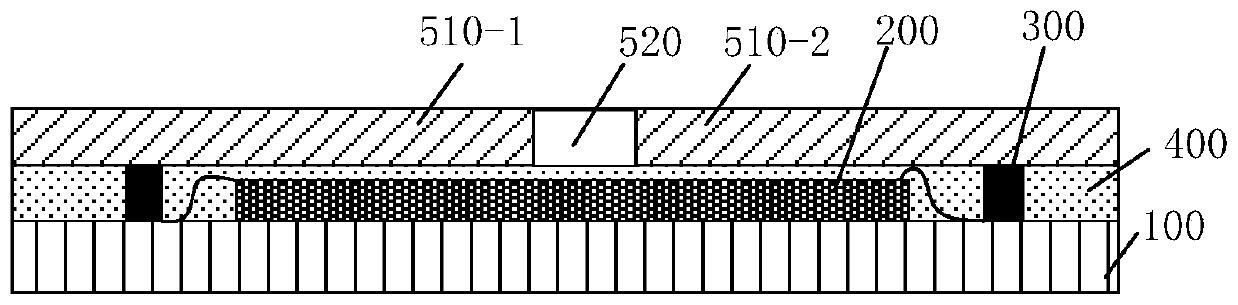

[0039] At present, in related technologies, a touch key is connected to a metal ring to realize standby wake-up and reduce standby power consumption of the fingerprint chip. After the fingerprint chip enters sleep mode, the system automatically cuts off the power of the fingerprint sensor and MCU, leaving the Touch key on standby to wake up the MCU and fingerprint sensor after a finger touch. The standby power consumption of this solution is 6-10uA, and a metal ring must be added around the fingerprint sensor, which will greatly increase the cost and production difficulty, complicate the finished product structure design, and reduce the yield rate of the product. Based on the above technical problems, this embodiment provides a method for preparing a fingerprint chip module. The traditional outer metal ring is replaced by conductive pillars and coated with conductive ink on the corresponding area of the fingerprint chip, and the conductive ink is used to increase the conducti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap