Novel slitting-free pole piece structure of lithium ion power battery

A technology for power batteries and battery pole pieces, which is applied in the field of new-type slitting-free pole piece structures, can solve problems such as changes in alignment, easy decoiling of pole rolls, and impact on battery production yield, achieving scientific structural design and reducing production Effect of cost, significant production practice significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

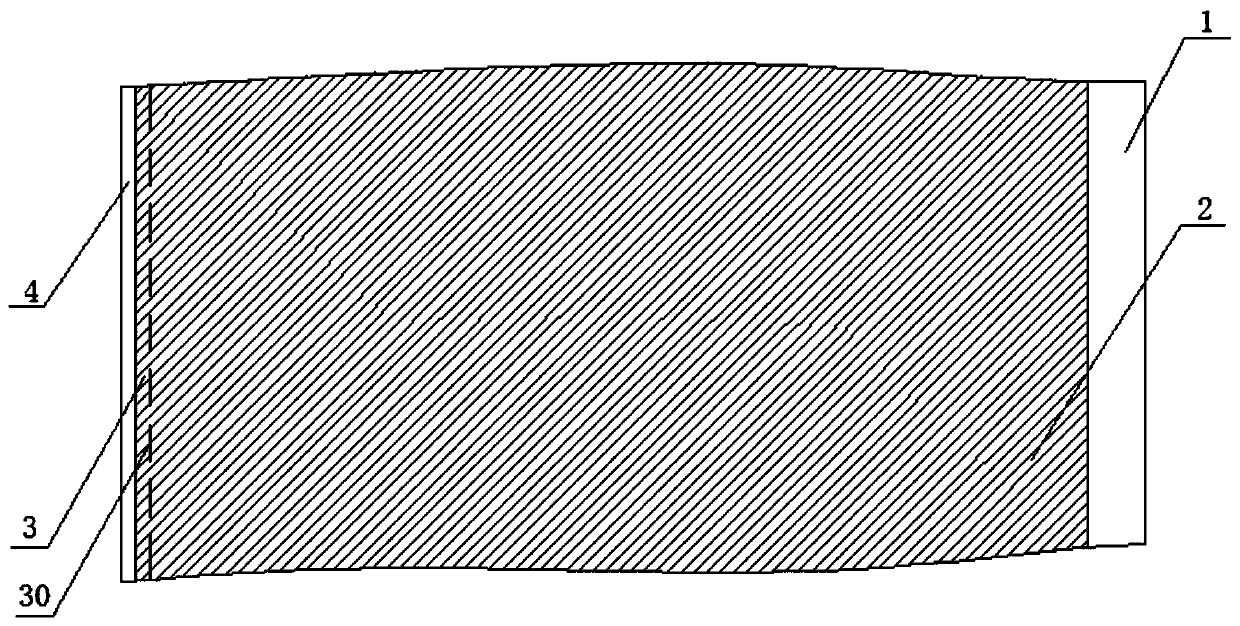

[0020] see figure 1 , the present invention provides a novel cutting-free pole piece structure for a lithium-ion power battery, comprising a battery pole piece foil body (for example, the positive pole piece foil body is aluminum foil, and the negative pole piece foil body is copper foil) and coated The active material layer applied on the surface of the main body of the battery electrode sheet foil;

[0021] There are longitudinally distributed active material regions 2 on the main body of the battery electrode sheet foil, and the surface of the active material region 2 is coated with an active material layer (such as a positive electrode active material layer or a negative electrode active material layer);

[0022] The reserved foil mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com