Vehicle-mounted disinfection spraying mechanism

A technology of spray box and single-chip microcomputer is applied in disinfection, sanitary equipment for toilets, atomized substances, etc., which can solve the problems of consuming a lot of manpower and material resources, difficult to complete disinfection, and restricting the widespread use of disinfection vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of these embodiments is used to help understand the present invention, but does not constitute a limitation to the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

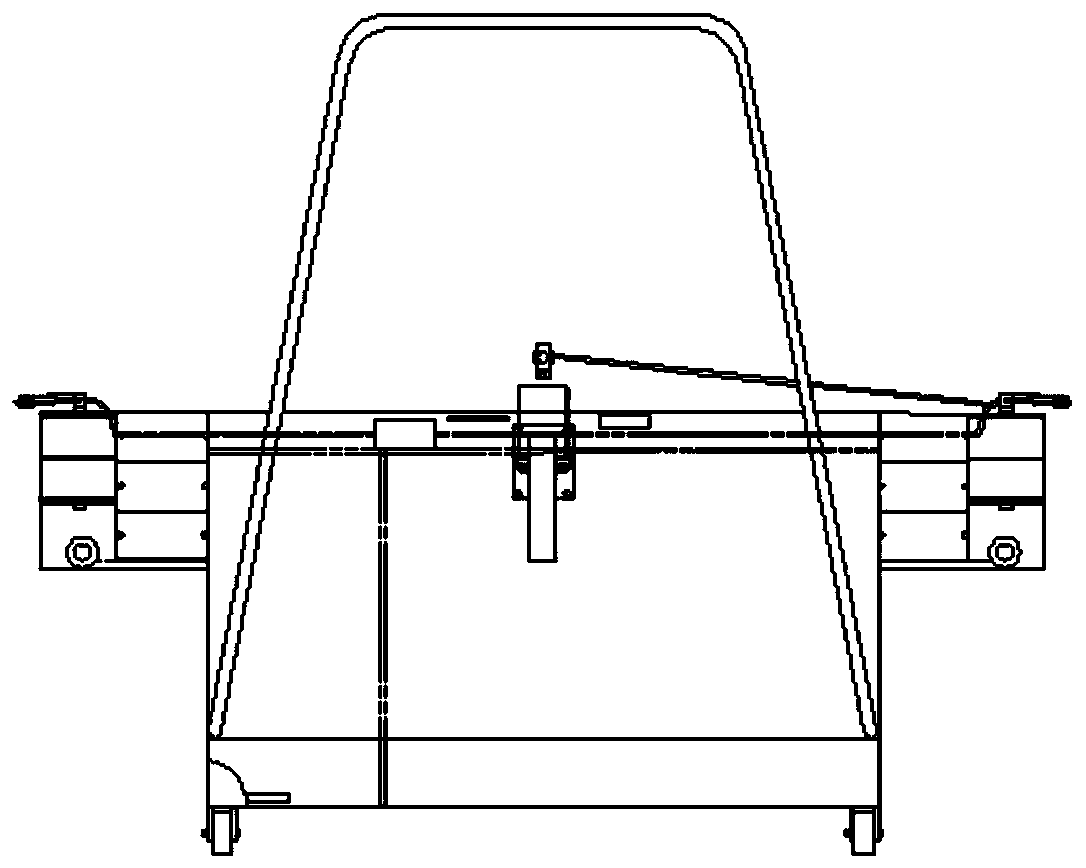

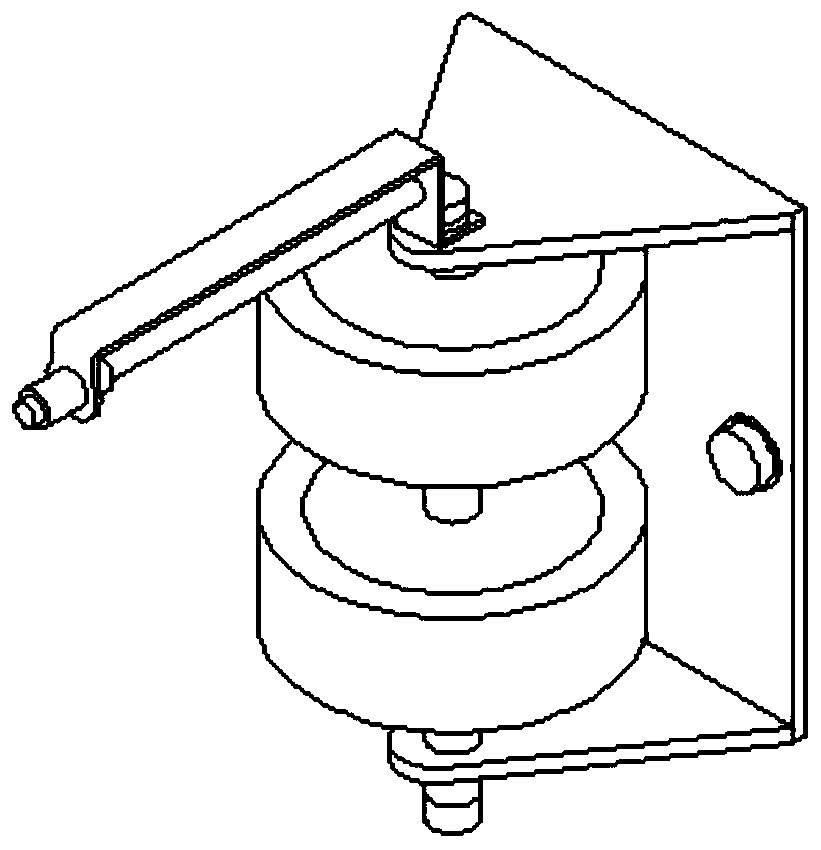

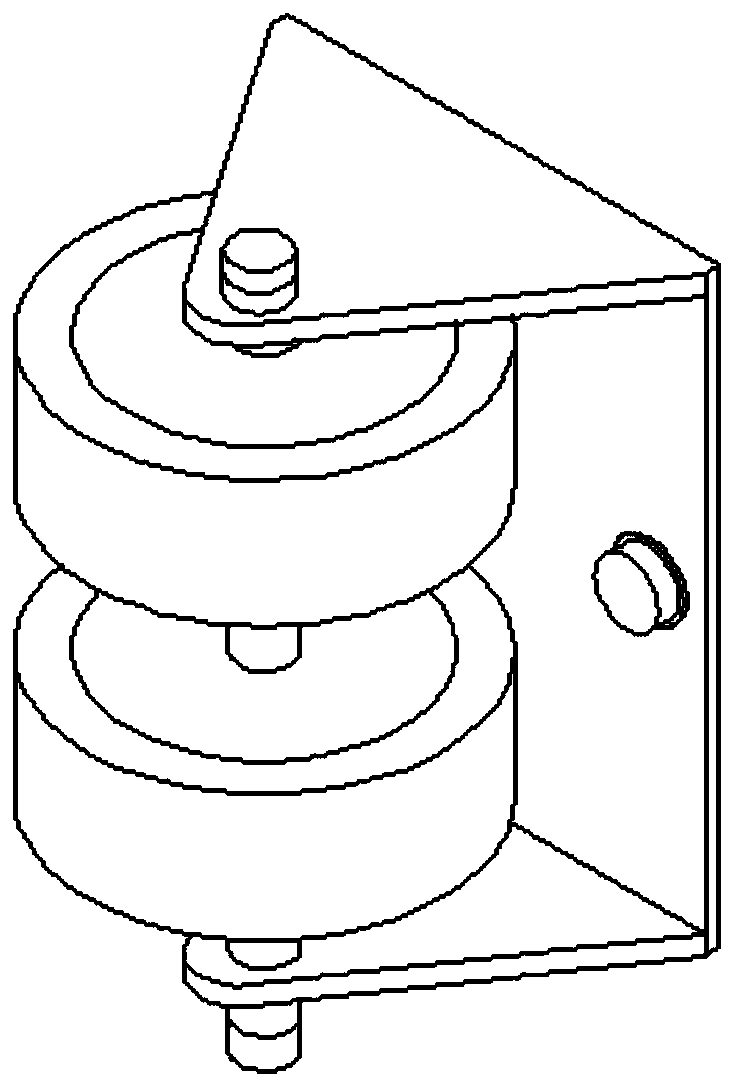

[0024] according to Figure 1-4 Shown:

[0025] A disinfection spraying mechanism for vehicles, including:

[0026] The spray box 1 includes a pulley 11, a ball valve 12, a pump 13, an external arm seat 14, a single-chip computer 15, and an alarm 16. The pulleys 11 are respectively arranged at the bottom of the spray box 1, and the ball valve 12 is arranged in the spray box 1. Inside, the water pump 13 is arranged at the top of the spray box 1 and includes a sealing block plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com