Ball-point pen refill recovery pretreatment device

A pretreatment device and ballpoint pen refill technology, applied in the field of educational supplies, can solve problems such as time-consuming and laborious, damage to staff, and affect the quality of recycled products, and achieve the effect of subtracting the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

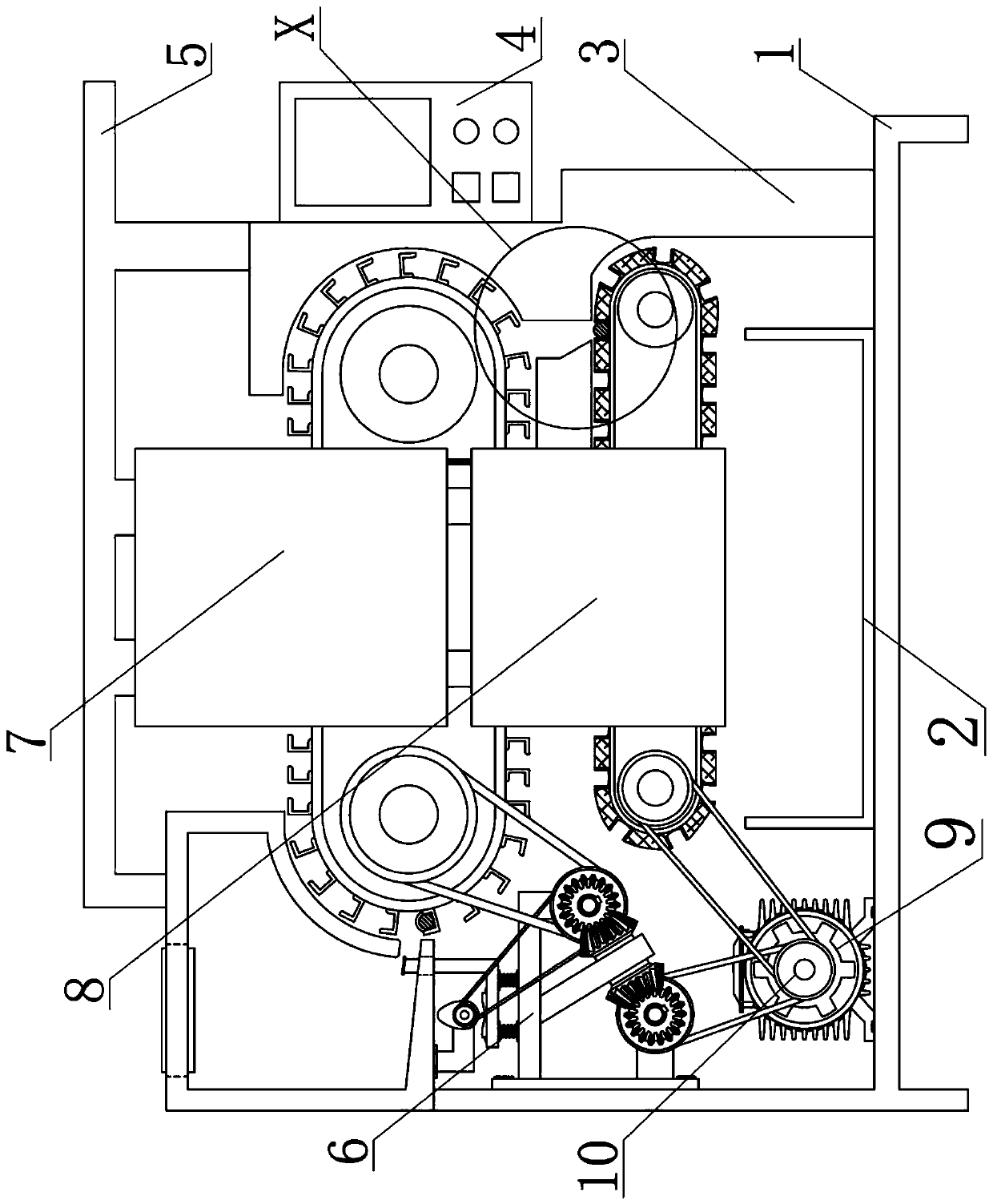

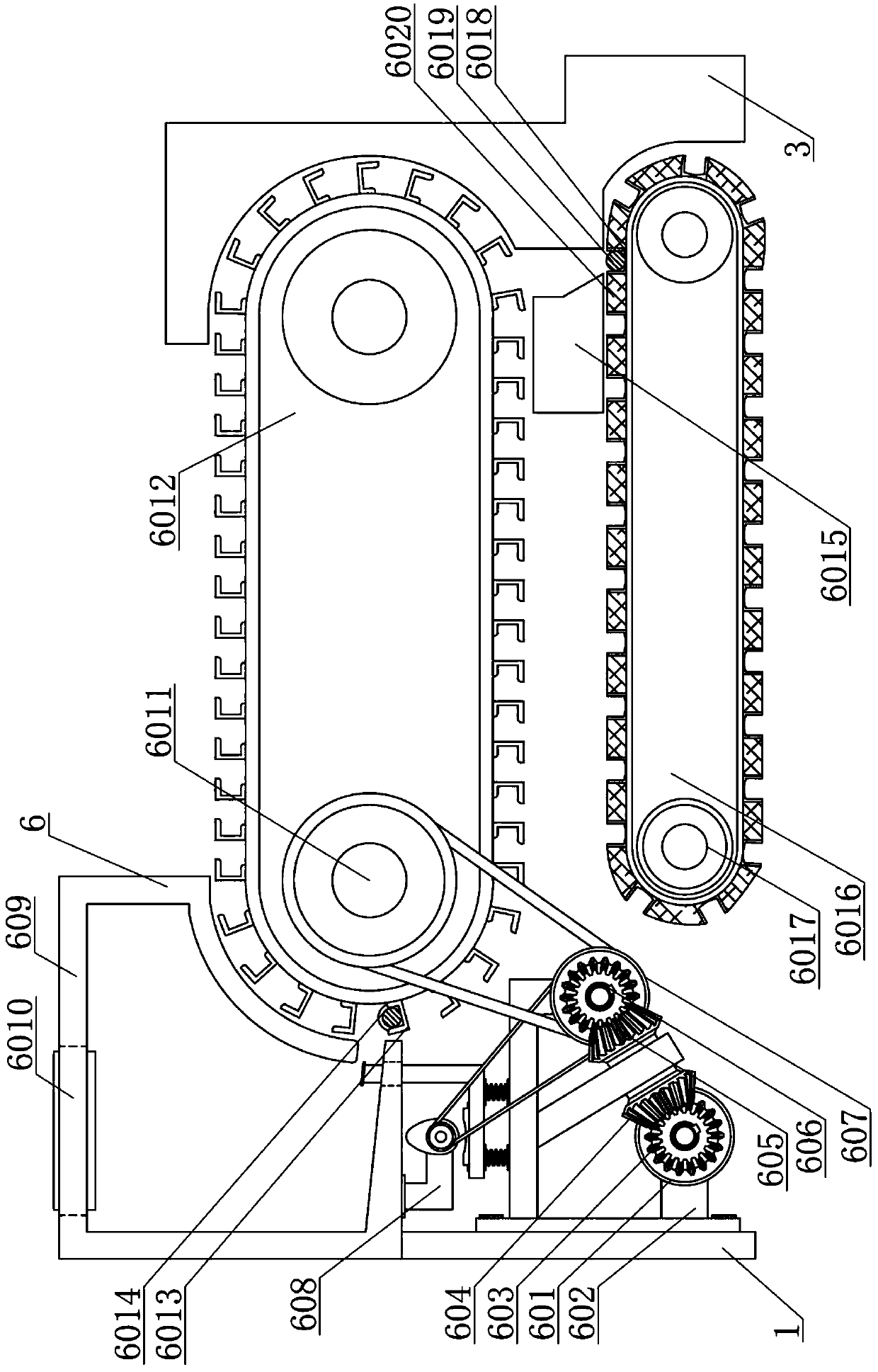

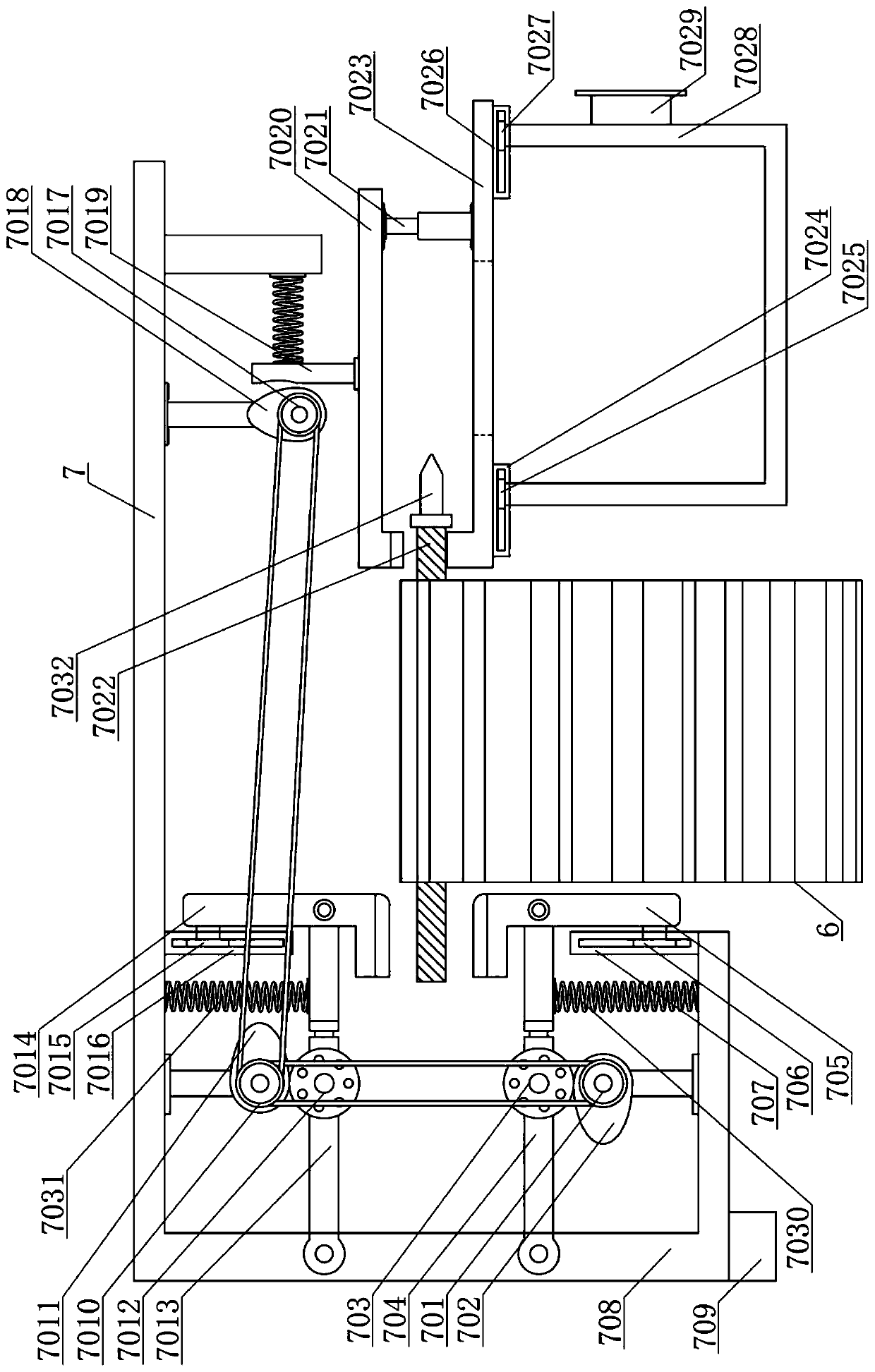

[0029] A ballpoint pen refill recovery pretreatment device, such as Figure 1-8 As shown, it includes a bottom frame 1, a first collection basket 2, a support baffle 3, a control display screen 4, a top support frame 5, a transmission mechanism 6, a nib removal mechanism 7, a grinding mechanism 8, a first motor 9 and a first transmission Wheel 10; the middle part of the inner bottom end of the underframe 1 is provided with a first collection basket 2; the right part of the inner bottom end of the underframe 1 is welded with the support baffle plate 3; the top of the inner left end of the underframe 1 is connected with the transmission mechanism 6; the underframe 1 The left part of the inner bottom end is bolted to the first motor 9 through a nut; a control display screen 4 is arranged on the top of the right end of the support baffle 3; The left part of the end is connected with the transmission mechanism 6; the middle left part of the bottom end of the top support frame 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com