Coke oven bridge pipe wall damage point repairing method and device

A repair method and bridge tube technology, which is applied to coke ovens, coke oven heating, coke oven parts, etc., can solve problems such as long processing time, high cost of spare parts, and high safety risks, so as to reduce labor intensity and save replacement costs , The effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

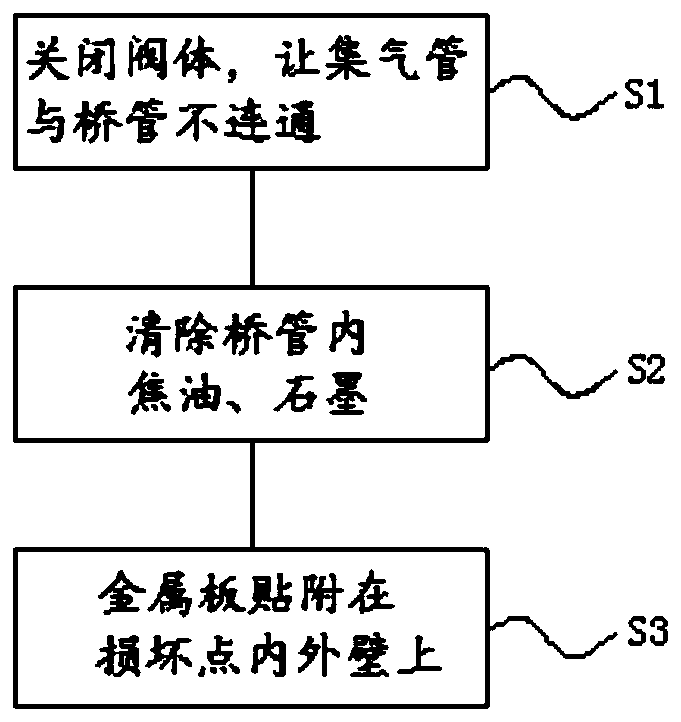

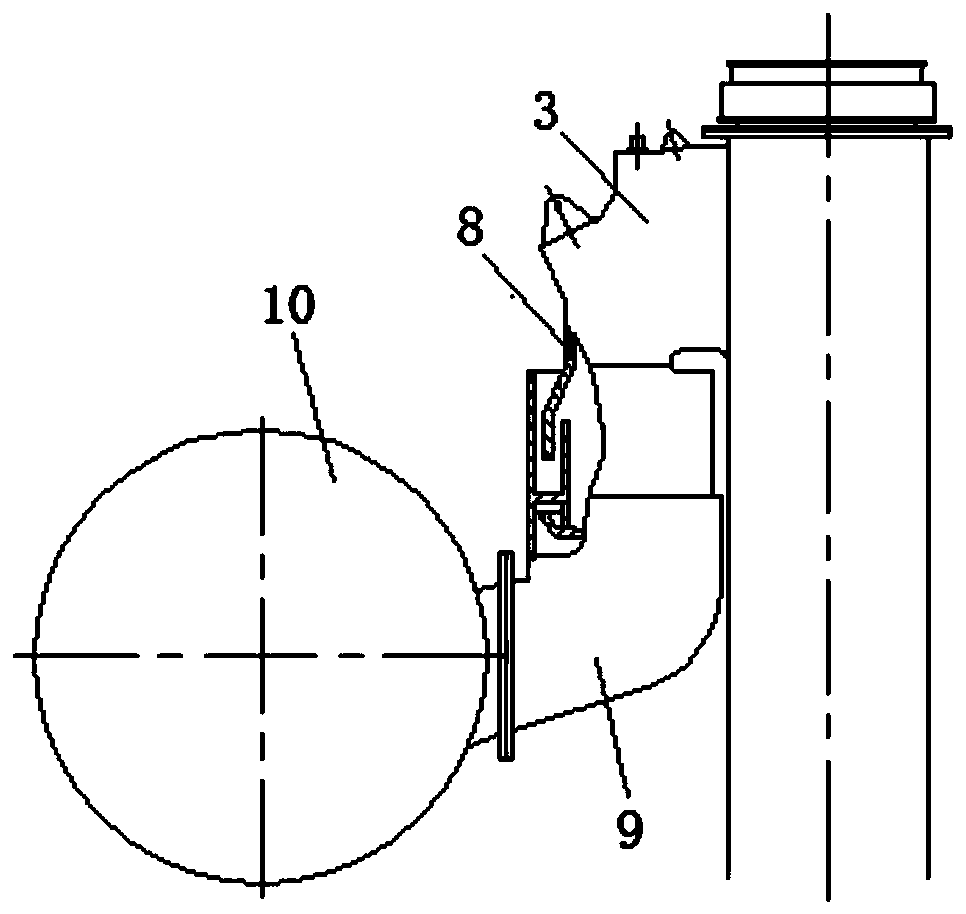

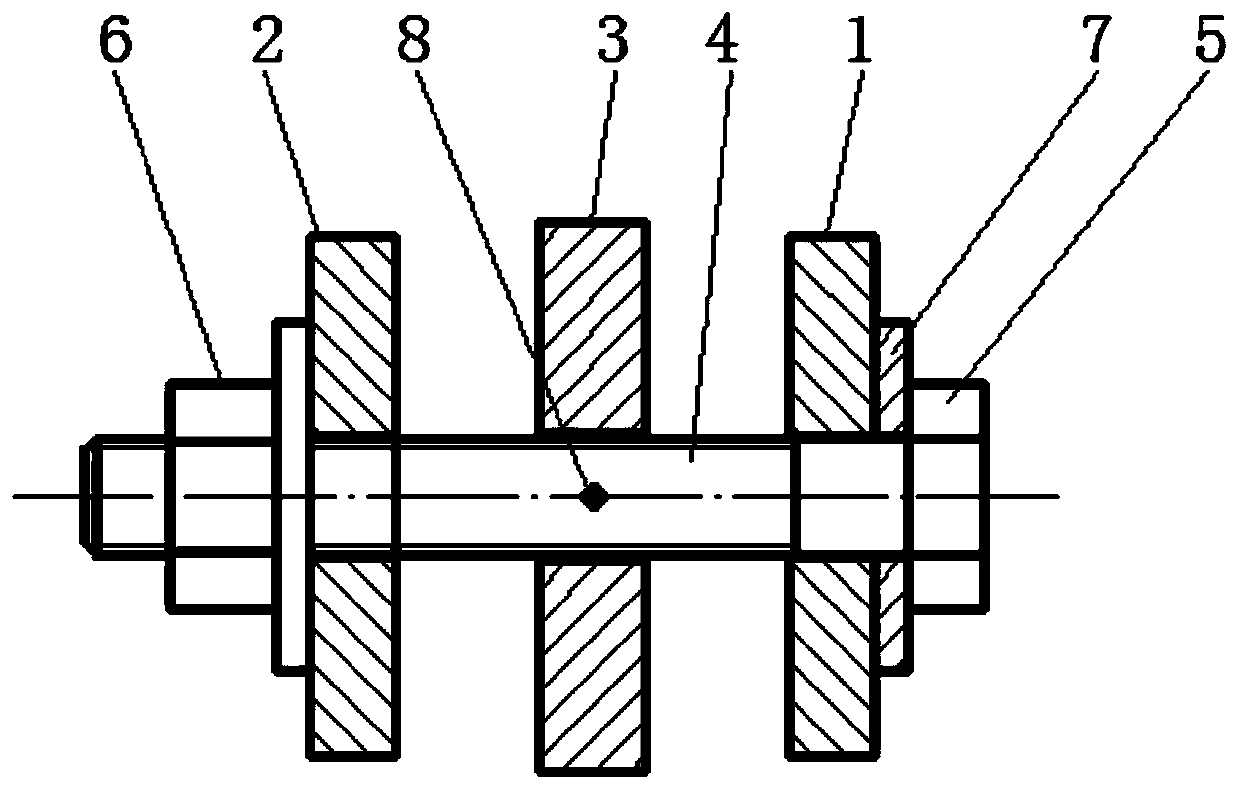

[0025] see figure 1 and figure 2 , a method for repairing the damaged point of the coke oven bridge tube wall, selecting the damaged point of the coke oven bridge tube wall at the end of coking in the carbonization chamber to repair; the specific repair process includes:

[0026] S1: first close the valve body 9, so that the gas collecting pipe 10 can no longer communicate with the bridge pipe 3, and avoid high-temperature gas in the bridge pipe 3;

[0027] S2: Then remove the tar and graphite in the bridge tube 3;

[0028] S3: When starting the repair, select two meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com