Flexible anti-collision sheath of telegraph pole

A technology for anti-collision sheaths and utility poles, applied in roads, buildings, road safety devices, etc., can solve the problems of poor toughness of utility poles and the inability to improve the ability of utility poles to resist impact, so as to reduce hard injuries and reduce collisions The effect of broken risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

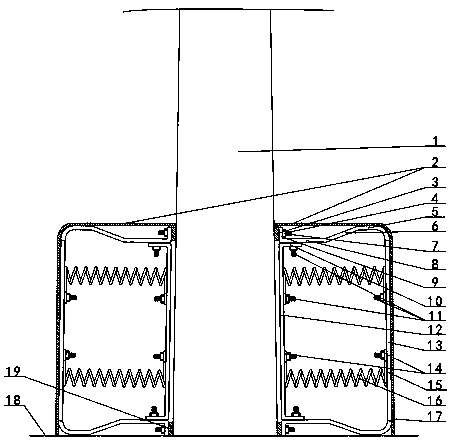

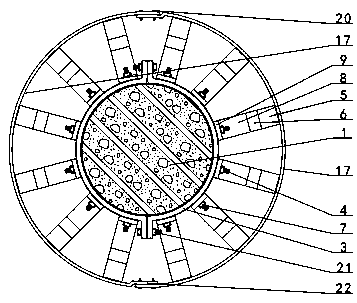

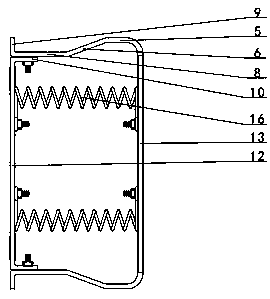

[0026] combined with Figure 1-7 The flexible anti-collision sheath of the utility pole described in includes the upper hoop 3, the lower hoop 19, the outer long vertical plate 13, the inner long vertical plate 12, the spring 16 and the outer cylinder 17, which are wrapped on the double semicircular structure. The outer edge surface of hoop 3 and lower hoop 19 is provided with a plurality of radially distributed screw rods A4, the upper hoop 3 is arranged on the lower outer edge surface of utility pole 1, and the lower hoop 19 is arranged on the lower end outer edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com