Equipment base

A technology of equipment and base, applied in the field of equipment base, can solve the problems of uneconomical and environmental protection, poor construction convenience, non-adjustable, etc., and achieve the effect of reducing production cost, reducing self-weight, and reducing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

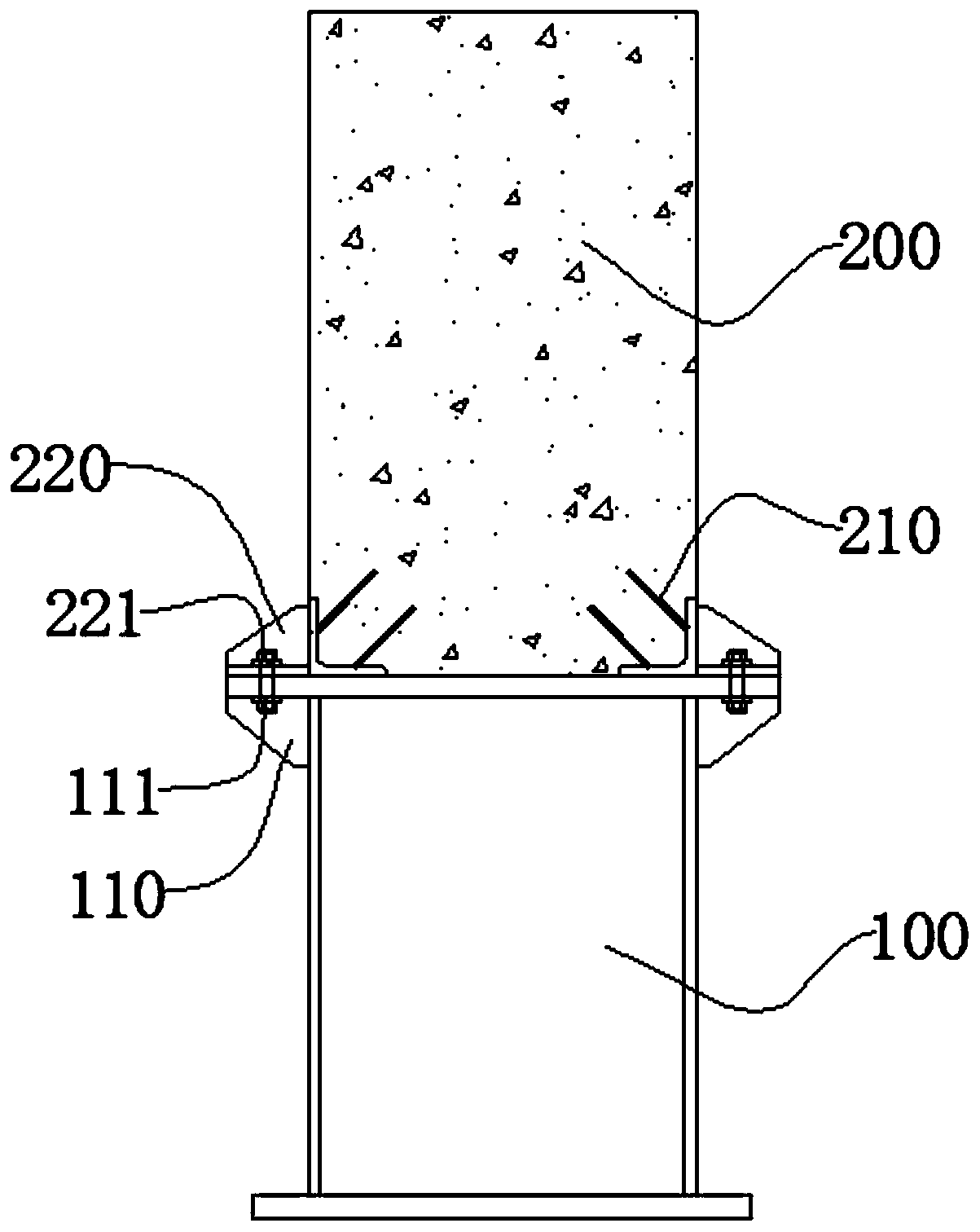

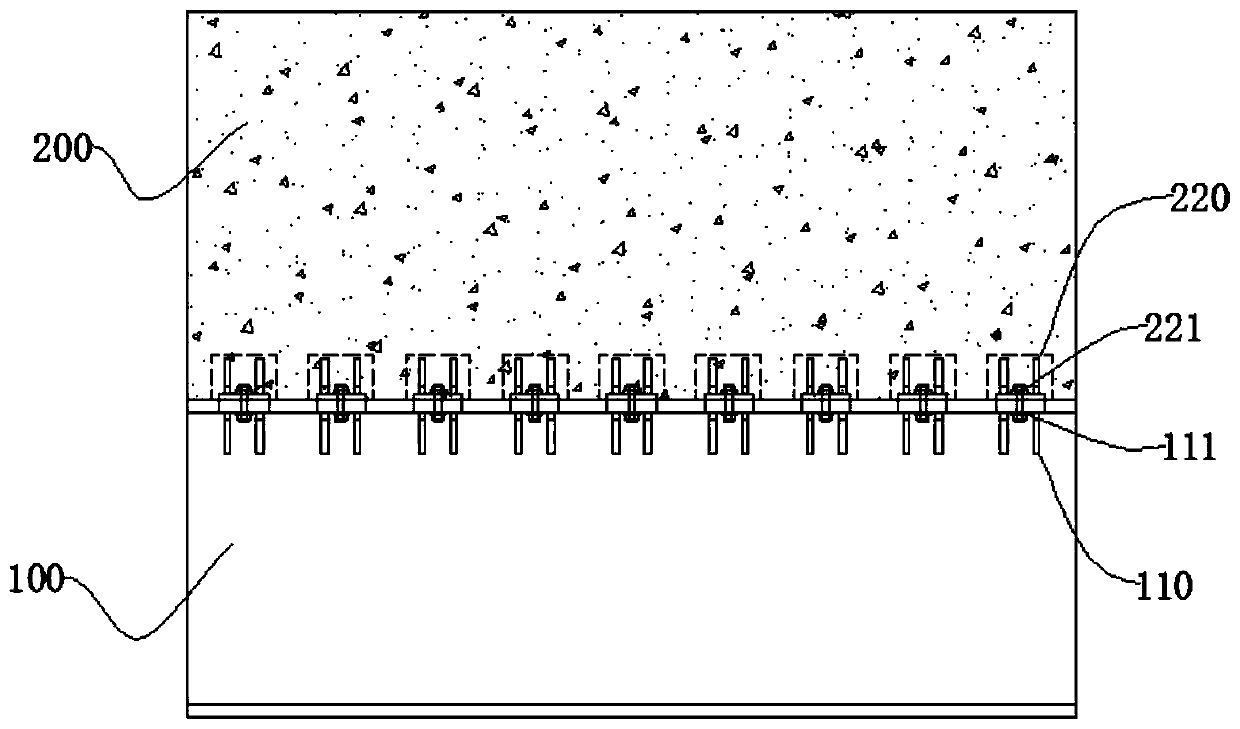

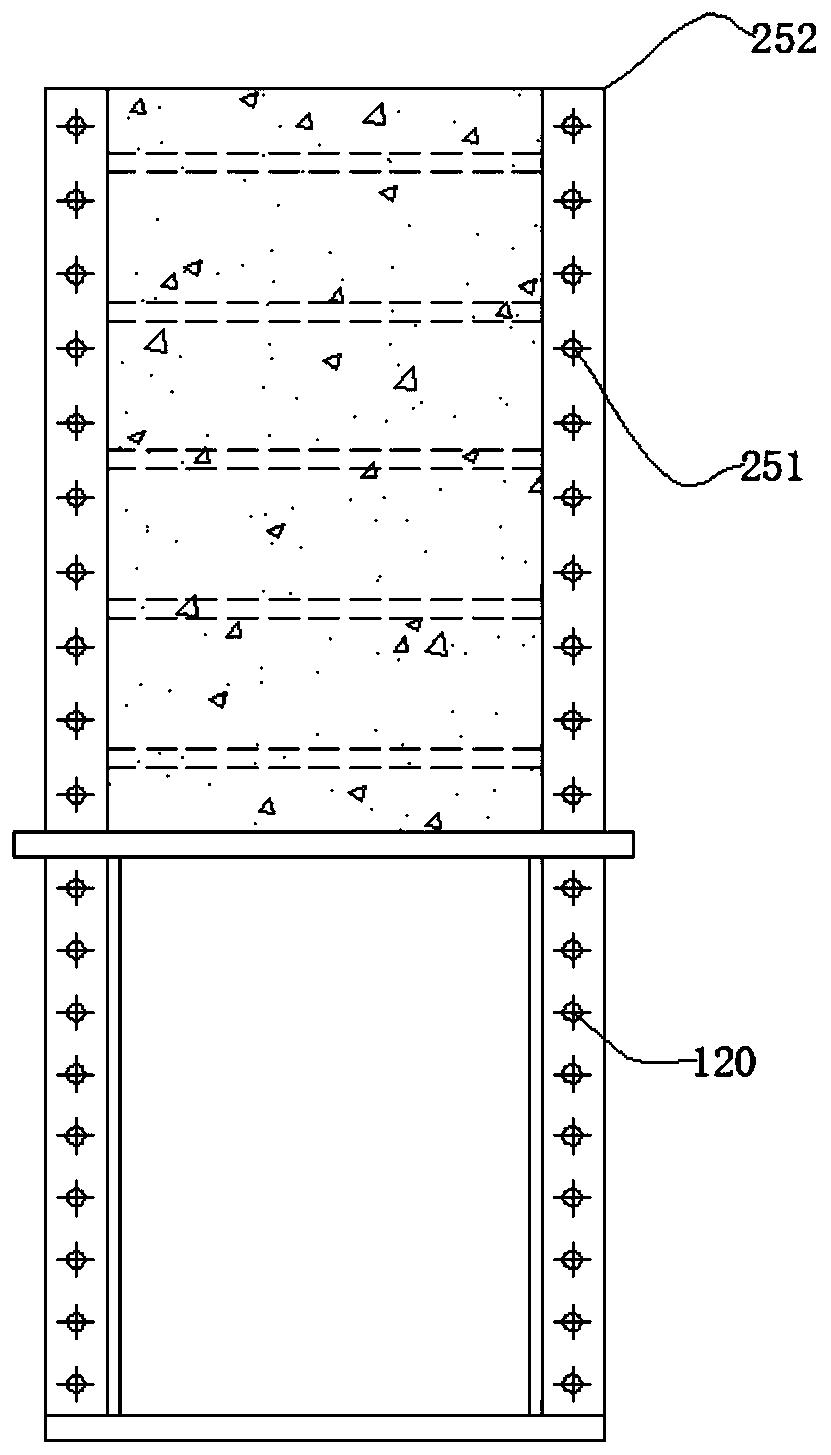

[0031] refer to Figure 1-8 , is a schematic diagram of the device base provided in this embodiment. refer to figure 1 A load-bearing base of the equipment base in this embodiment includes a steel main beam 100 and a prefabricated concrete beam 200, the precast concrete beam 200 is erected on the steel main beam 100, the side of the steel main beam 100 includes a first raised structure 110, the second A protruding structure 110 is provided with a first through hole 111, and the interior of the precast concrete beam 200 is provided with an embedded part 210, and also includes a second protruding structure 220, and the second protruding structure 220 is fixed on the internal embedded part 210, Moreover, a second through hole 221 is opened on the second protruding structure 220 .

[0032] During specific implementation, the prefabricated concrete beam 200 is erected on the steel main beam 100, the first through hole 110 is matched with the second through hole 220, and the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com