Built-in corner plugin

A plug-in and corner technology, applied in the field of built-in corner plug-ins, can solve the problems of single structure of external joints, low construction efficiency, troublesome installation process, etc., achieve flexible quantity and fixed positions, improve construction efficiency and construction steps little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

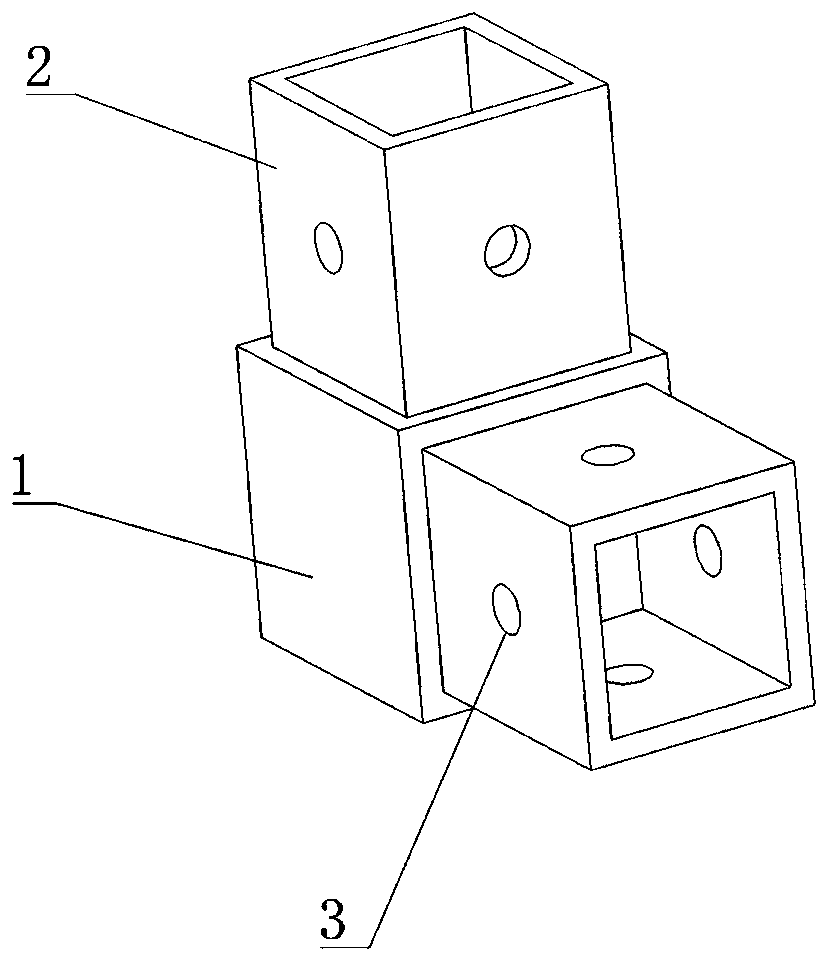

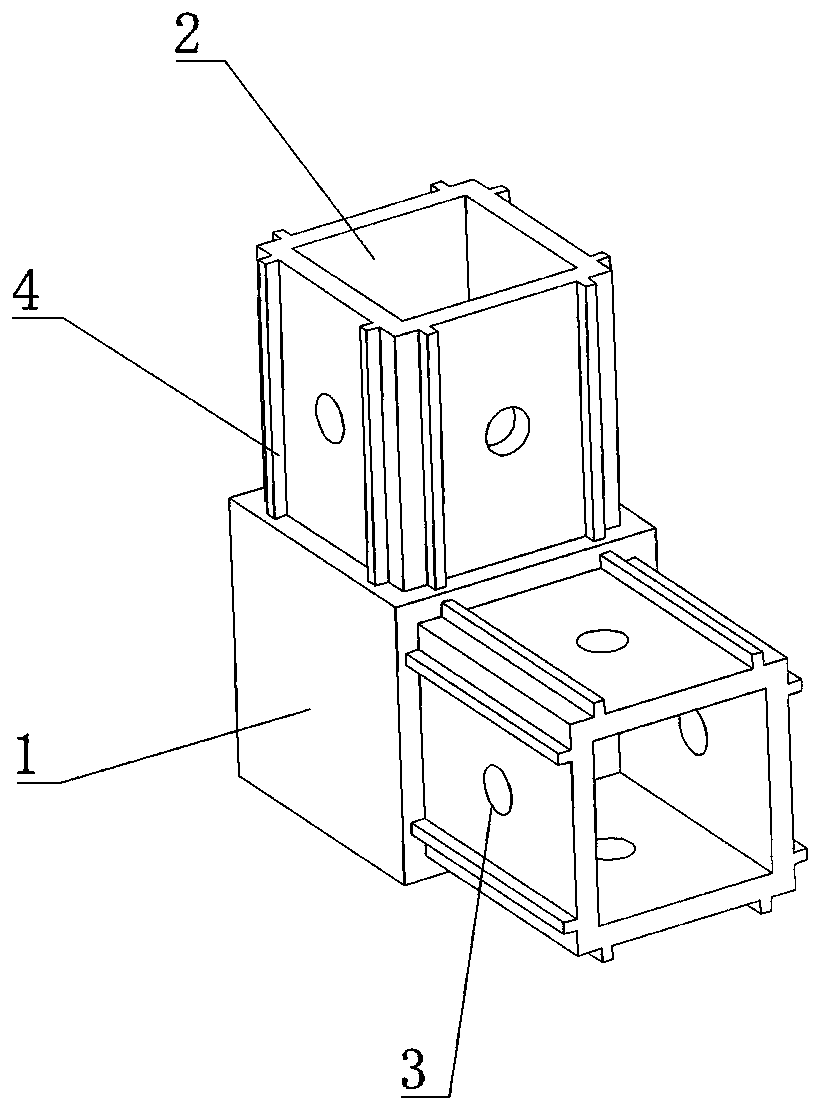

[0032] see Figure 1-Figure 5 As shown, this embodiment provides a built-in corner insert, including a mounting part 1 and two tubular corner parts 2, the mounting part 1 is provided with six mounting surfaces 8; one end of the corner part 2 is connected to the mounting part 1 The mounting surface 8 of the corner portion 2 is fixed, and the side surface of the corner portion 2 is provided with a connection structure. .

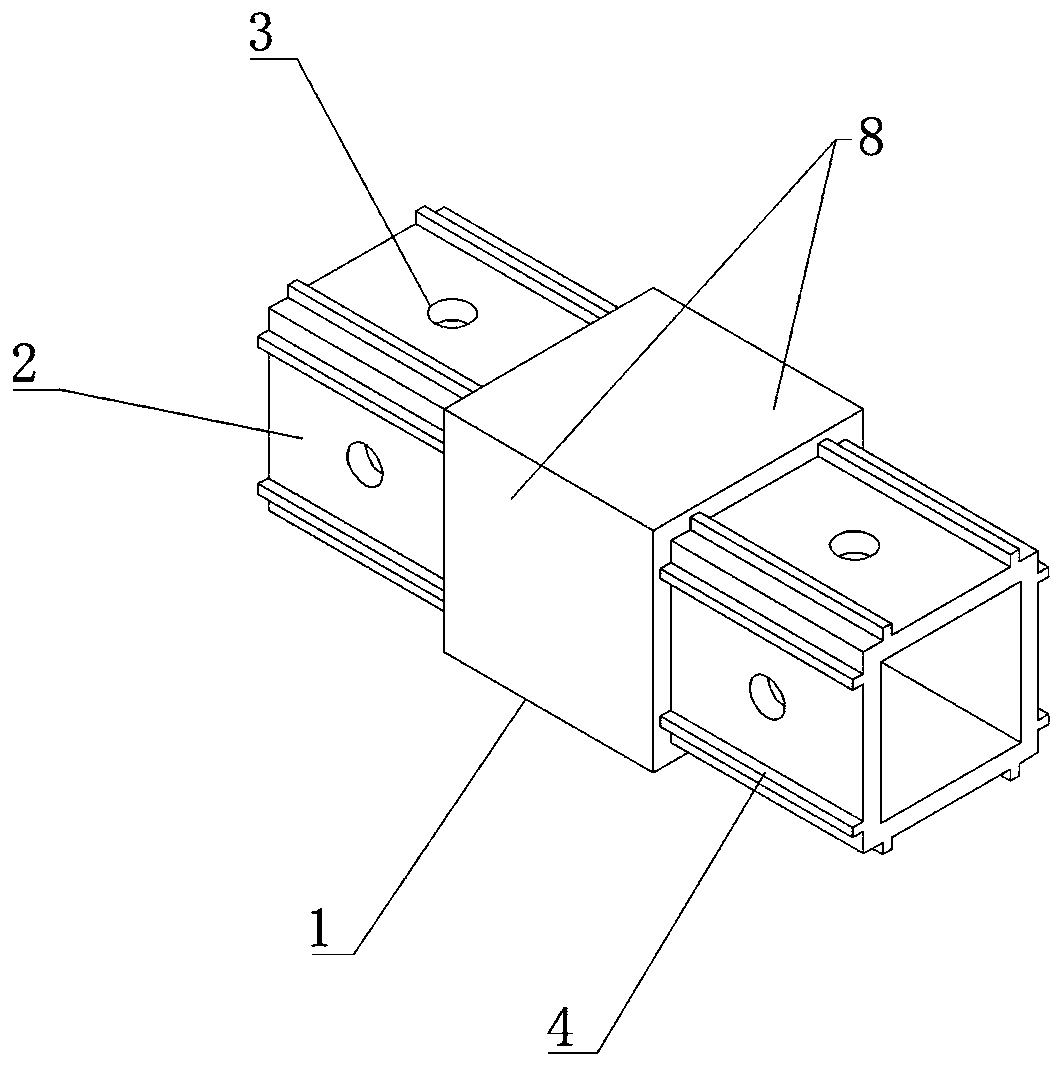

[0033] During specific implementation, the installation part 1 in this embodiment is a hollow hexahedron, and the six faces of the hexahedron are the six installation surfaces 8 of the installation part 1; see figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the two corners 2 are respectively fixed to two adjacent installation surfaces 8 on the installation part 1, and at this time the two corners 2 are perpendicular to each other; see image 3 As shown, the two corner portions 2 can also be respectively fixed to two opposite mounting surfaces 8 on ...

Embodiment 2

[0039] see Figure 6 and Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the number of the corners 2 is three, and the three corners 2 are respectively fixed to any three mounting surfaces 8 on the mounting portion 1; between the three corners 2 The two are perpendicular to each other (see Figure 7 ) or the three corners 2 are coplanar (see Figure 6 ). Figure 6 and Figure 7 It only shows that the connection structure on the corner 2 is a through hole 3 and has a buffer edge 4, the structure of the corner 2 in this embodiment can also be the same as figure 1 or Figure 4 or Figure 5 The structure of the middle corner part 2 is the same.

Embodiment 3

[0041] see Figure 8 and Figure 9As shown, the difference between this embodiment and embodiment 1 is that the number of the corner portions 2 is four, and the four corner portions 2 are respectively fixed to any four mounting surfaces 8 on the mounting portion 1 . In this embodiment, there are two combinations of the corner part 2 and the mounting part 1, namely Figure 9 The four corners shown in 2 are coplanar, Figure 8 The four corners 2 shown in are not coplanar. Figure 8 and Figure 9 It only shows that the connection structure on the corner 2 is a through hole 3 and has a buffer edge 4, the structure of the corner 2 in this embodiment can also be the same as figure 1 or Figure 4 or Figure 5 The structure of the middle corner part 2 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com