Concrete pouring equipment used for construction equipment

A kind of construction equipment and concrete technology, which is applied in the direction of construction, building structure, and construction material processing, etc. It can solve the problems that the concrete cannot be fully exported, intermittent, and affects the effect of pouring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

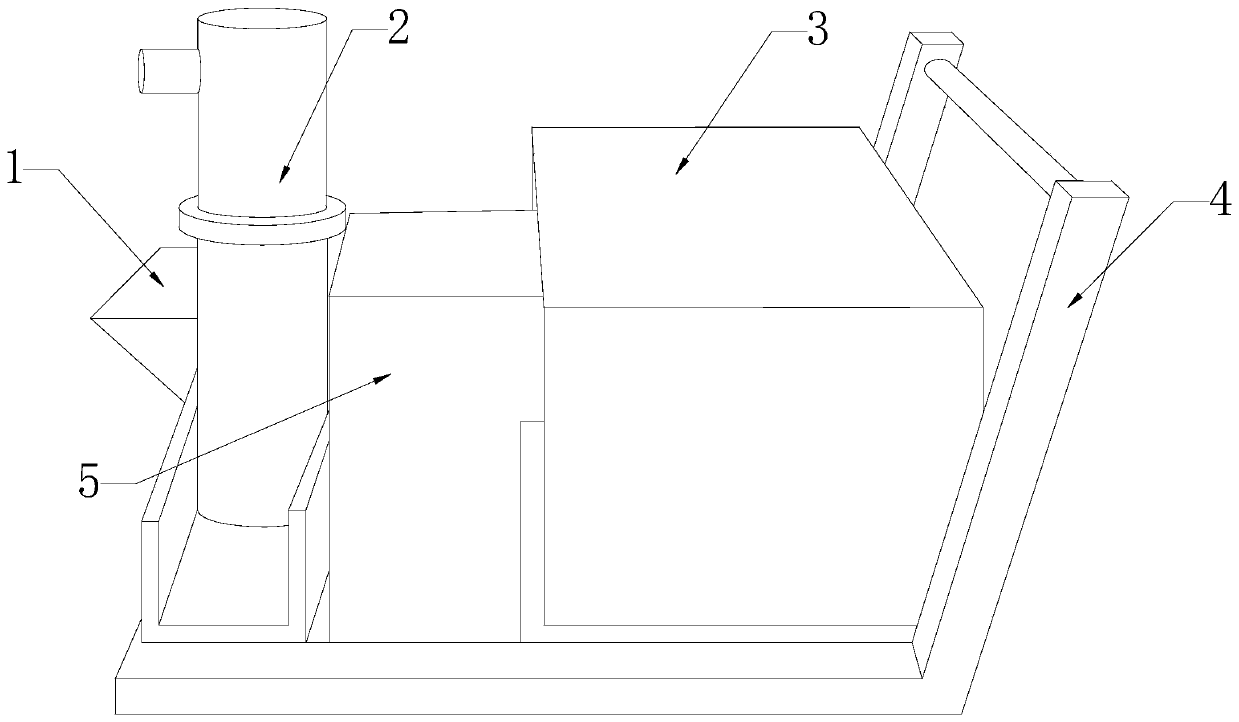

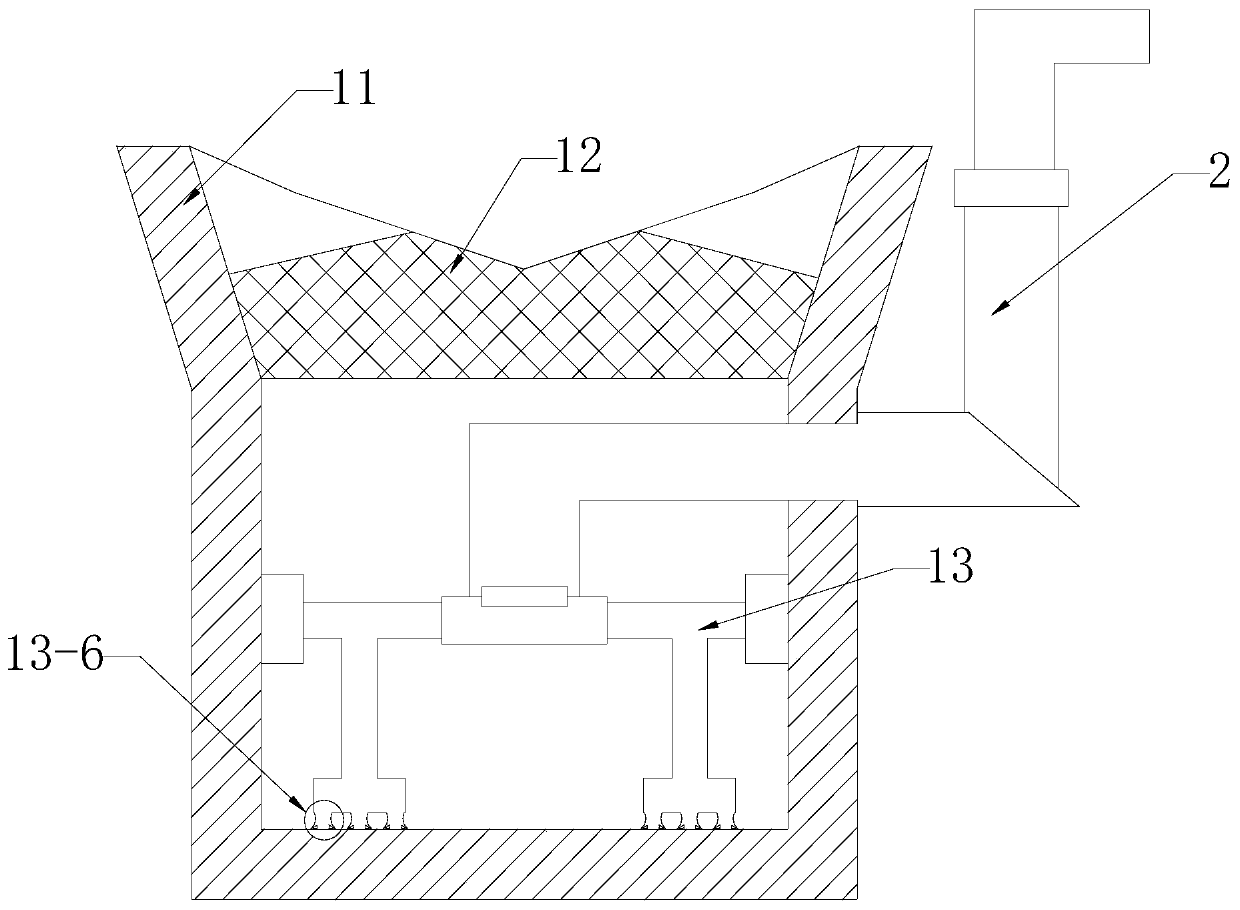

[0028] see Figure 1-Figure 4 , a concrete pouring equipment for construction equipment, the present invention provides a concrete pouring equipment for construction equipment, in view of the deficiencies in the prior art, the present invention is achieved through the following technical solutions: a concrete pouring equipment for construction equipment, its The structure includes a processor 1, a discharge pipe 2, a body 3, a handle 4, and a control box 5. The rear of the body 3 is provided with a handle 4, and the control box 5 is installed in front of the body 3. The processor 1 and The machine body 3 is mechanically connected, and the processor 1 is movably connected with the discharge pipe 2 through a connecting shaft.

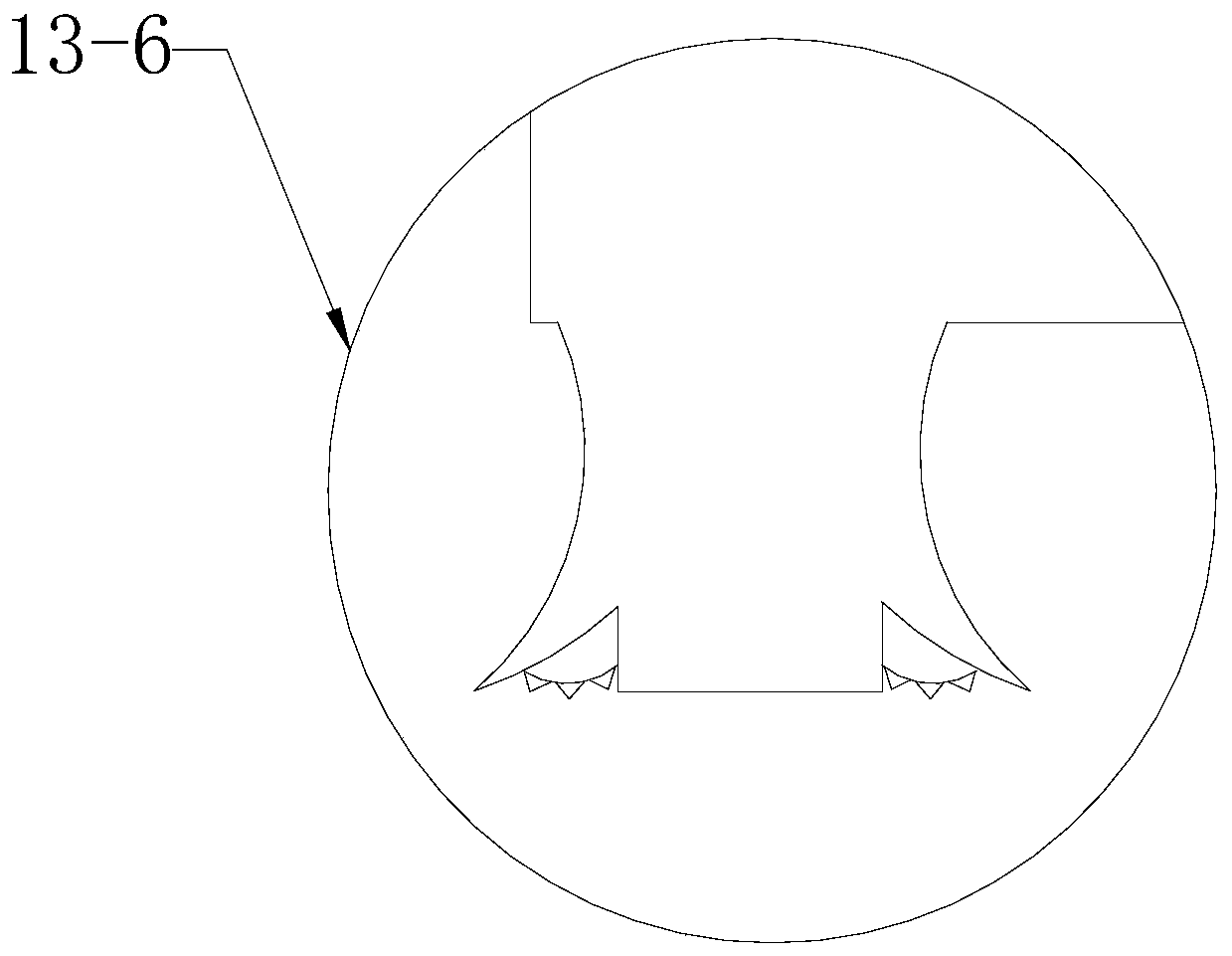

[0029] The processor 1 is composed of a cavity 11, a defoaming cavity 12, and an agitator 13, the cavity 11 is provided with a defoaming cavity 12, the agitator 13 is mechanically connected with the cavity 11, and the agitator 13 is movably connected wit...

Embodiment 2

[0036] see Figure 1-Figure 6 , a concrete pouring equipment for construction equipment, the present invention provides a concrete pouring equipment for construction equipment, in view of the deficiencies in the prior art, the present invention is achieved through the following technical solutions: a concrete pouring equipment for construction equipment, its The structure includes a processor 1, a discharge pipe 2, a body 3, a handle 4, and a control box 5. The rear of the body 3 is provided with a handle 4, and the control box 5 is installed in front of the body 3. The processor 1 and The machine body 3 is mechanically connected, and the processor 1 is movably connected with the discharge pipe 2 through a connecting shaft.

[0037] The processor 1 is composed of a cavity 11, a defoaming cavity 12, and an agitator 13, the cavity 11 is provided with a defoaming cavity 12, the agitator 13 is mechanically connected with the cavity 11, and the agitator 13 is movably connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com