Civil engineering building support column

A technology of civil engineering and construction, which is applied in the field of civil engineering building pillars, can solve the problems of insufficient support stability of support columns and insufficient flexibility of support column heights, and achieve the effects of ensuring smoothness, increasing service life, and ensuring support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

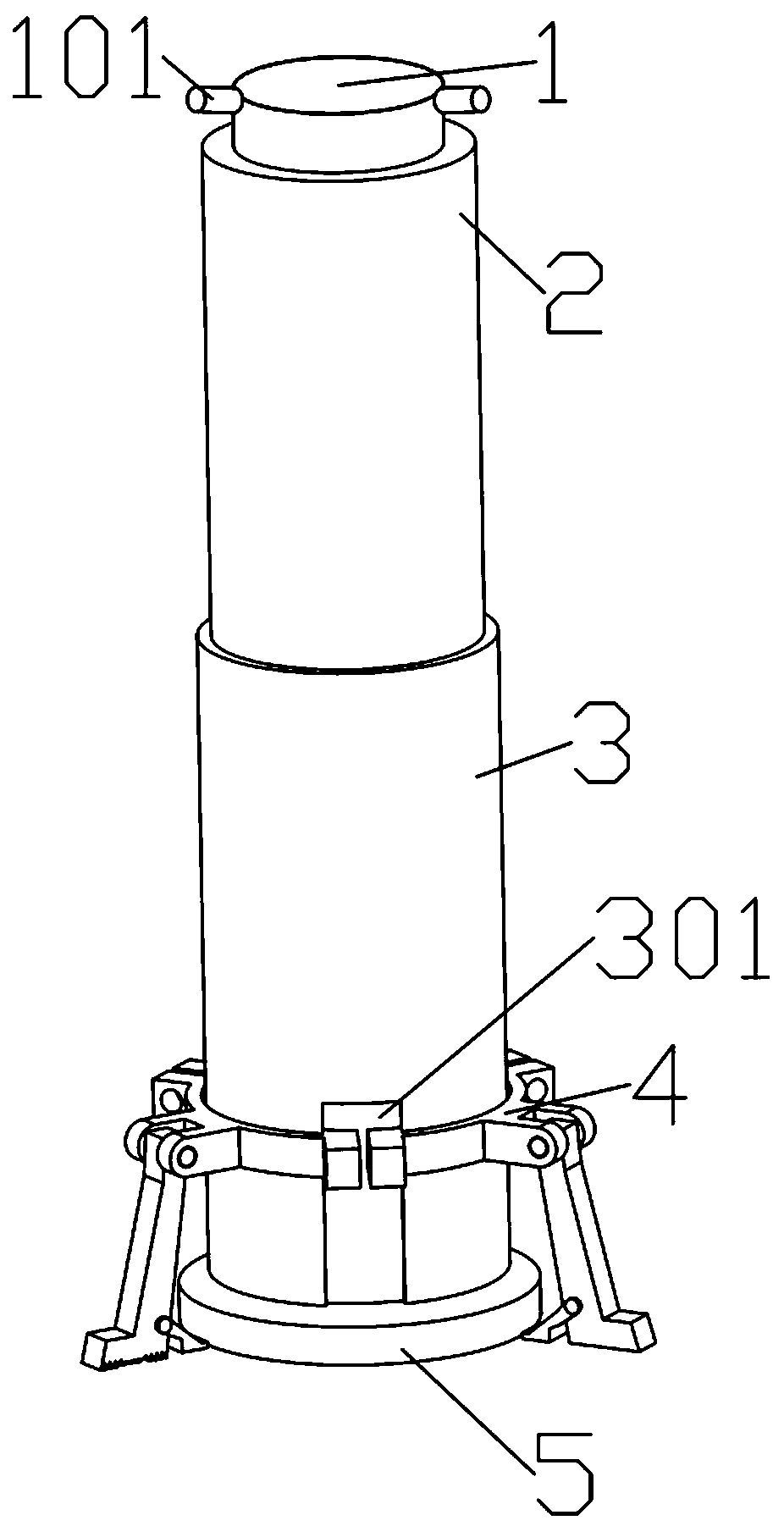

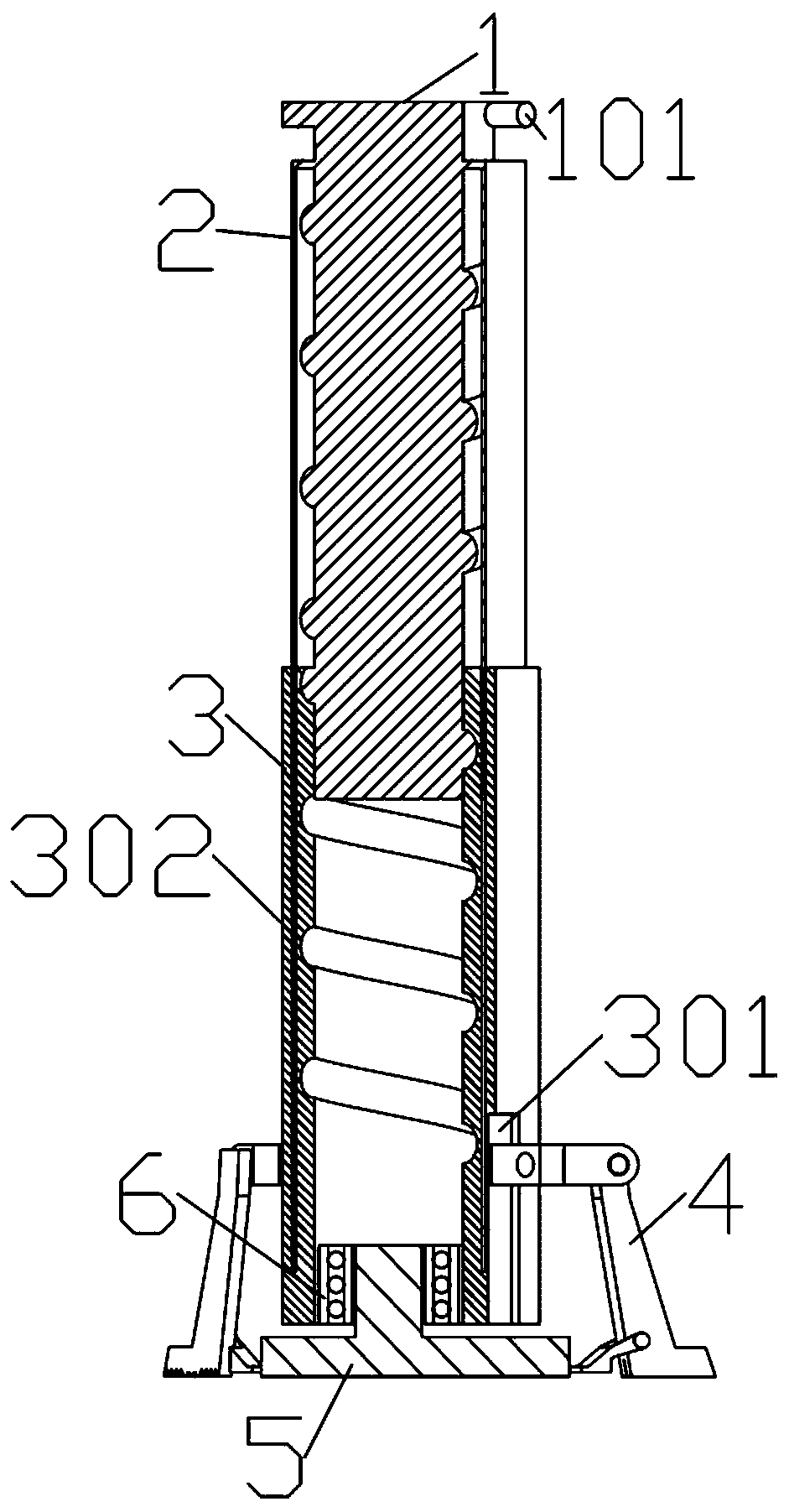

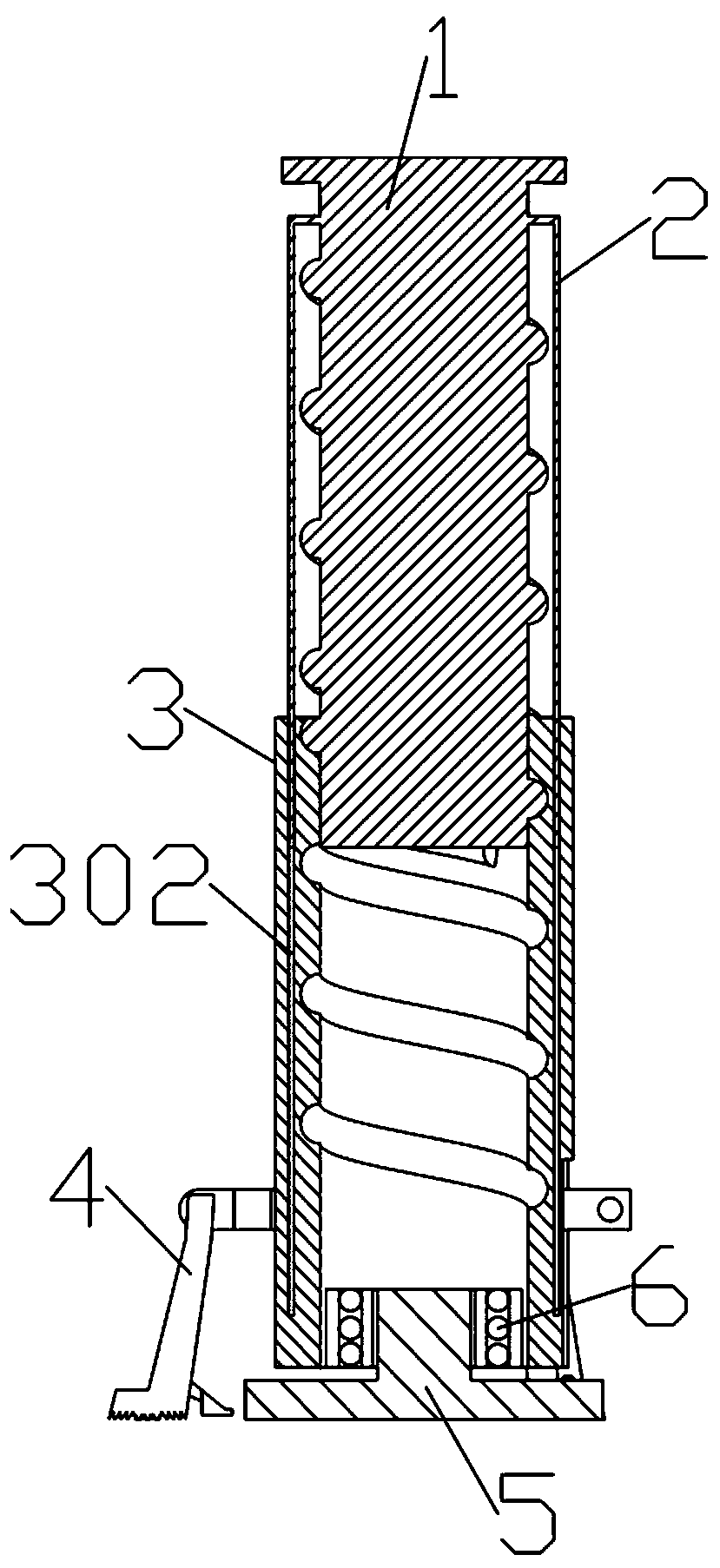

[0025] Below will be combined with the appended in the embodiment of the present invention Figure 1-5 , clearly and completely describe the technical solutions in the embodiments of the present invention.

[0026] see Figures 1 to 5 , the present invention provides a technical solution:

[0027] A civil engineering building pillar, comprising a support column 1, a fixed ear 101, a protective shell 2, a bottom column 3, a groove 301, a chute 302, a support frame 4, a support seat 5, and a rolling bearing 6, and the support frame 4 includes a fixed frame 401 , support feet 402, clamping blocks 403, bolt holes 404, auxiliary blocks 405, oblique sawtooth 406, raised columns 407, the outer wall of the supporting column 1 is spirally connected to the inner wall of the bottom column 3, the wall of the bottom column 3 is provided with a chute 302, and the protective shell 2 One end is fixedly connected to the upper part of the support column 1, the other end of the protective shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com