Automatic control system and control method for safety fence management

An automatic control system and safety fence technology, applied in the direction of fences, building types, buildings, etc., can solve the problems of lack of monitoring and management of safety fence status, increase the workload of power substation operation and maintenance personnel, etc., to achieve the protection of safe operation and automation High and low workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

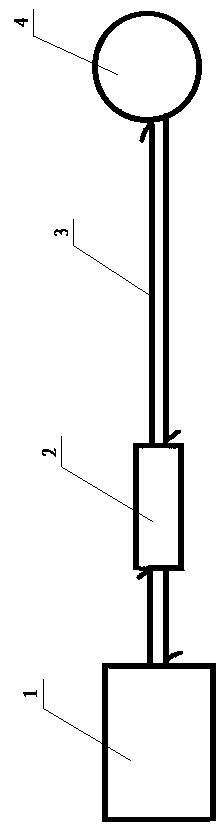

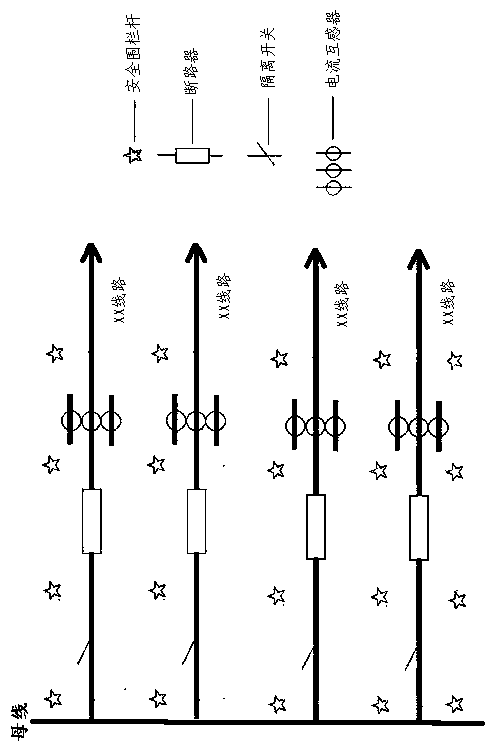

[0021] An automatic control system for safety fence management, which consists of: a safety fence management system, the safety fence management system includes a control device, the control device is composed of computer equipment and monitoring operation software, and the control device passes the light The signal is connected with the photoelectric converter, and the photoelectric converter is connected with a group of safety fence poles through power cables, and the safety fence poles have an automatic lifting mechanism.

Embodiment 2

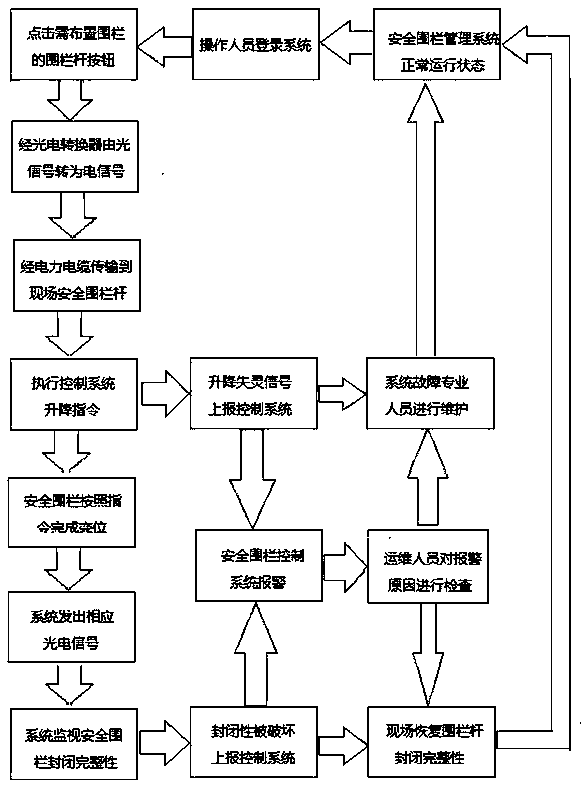

[0023] A control method using the safety fence management automatic control system described in Embodiment 1, the method is: (1) Control steps:

[0024] The operator arranges the safety fence poles in the safety fence management system in the control device, clicks the number of the fence to be arranged in the safety fence management system, and after the network information of the safety fence management system, that is, the optical signal exits, it passes through the transmission device. The photoelectric converter converts the optical signal into an electrical signal, and the electrical signal is transmitted to the automatic lifting safety fence pole with the corresponding number of the actuator through the power cable for specific control, and the position of the safety fence pole is monitored through the position displacement of the safety fence pole. Lifting state, this method has completely changed the traditional way of manually arranging safety fence poles by operators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com