Method and device for monitoring a texturing process

A technology of equipment and procedures, applied in the field of equipment monitoring the deformation process, can solve problems such as yarn quality defects, interference source identification, and decision-making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

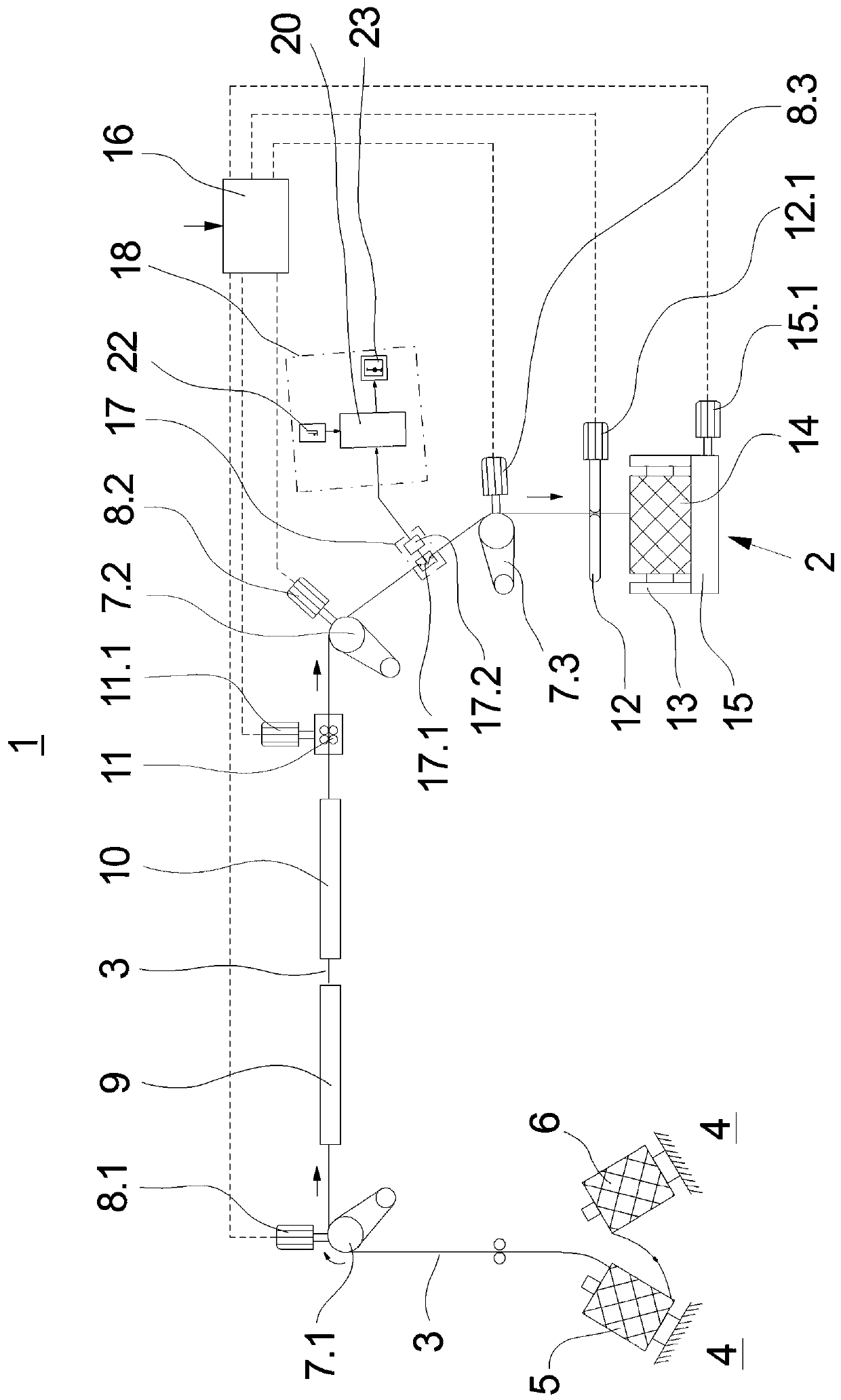

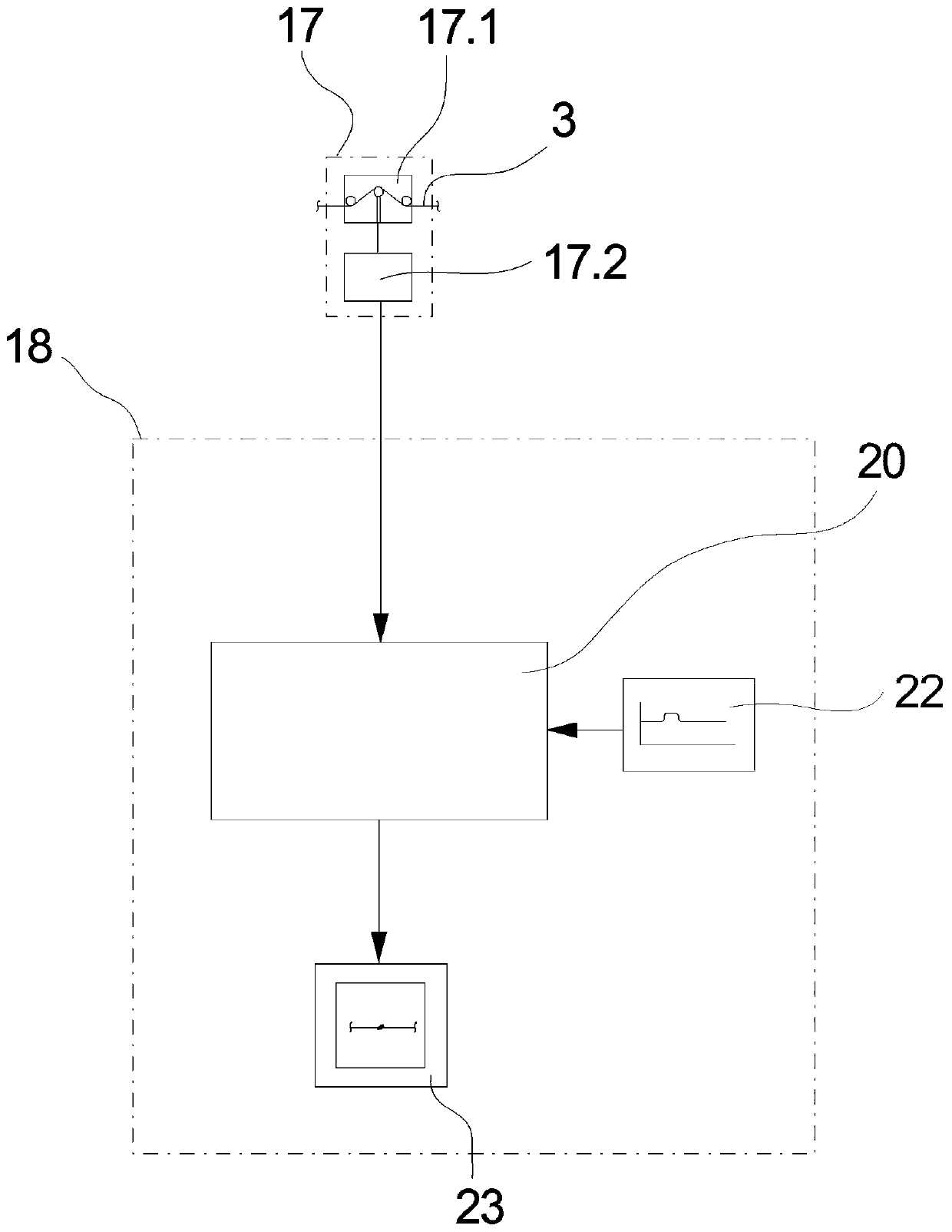

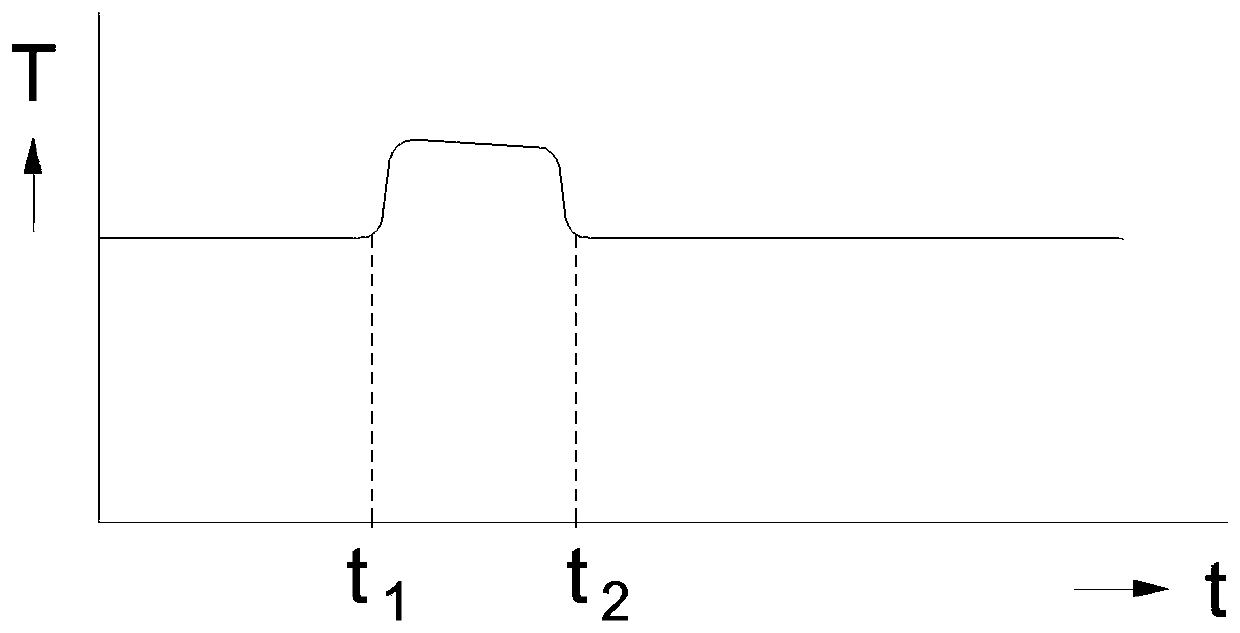

[0033] exist figure 1 An example of a texturing process for producing crimped yarn is schematically shown in . In this case, the deformation process is illustrated by a working station of the deformation machine. Such texturing machines usually have a number of processing stations in order to text a number of synthetic yarns in parallel. exist figure 1A processing station 1 and a bobbin station 2 of such a texturing machine are schematically shown in FIG. The processing station 1 has a creel 4 in which a supply bobbin 5 and a reserve bobbin 6 are held. The supply bobbin 5 supplies a yarn 3 which is conveyed in the processing station 1 for drawing and texturing. The yarn end of the supply yarn reel 5 is connected to the yarn start of the reserve yarn reel 6 via a yarn knot. This enables a continuous withdrawal of the yarn 3 after the supply bobbin 5 has been used up. The yarn end of the reserve yarn reel 6 is then connected to the yarn start of a new supply yarn reel 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com