Sieve plate for multi-shaft shearing type crushing machine

A shearing and crusher technology, which is applied in the direction of grain processing, etc., can solve the problems of material falling, sieve plate corrosion, and reduced crushing efficiency, etc., and achieve good crushing effect, strong impact resistance, and high crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

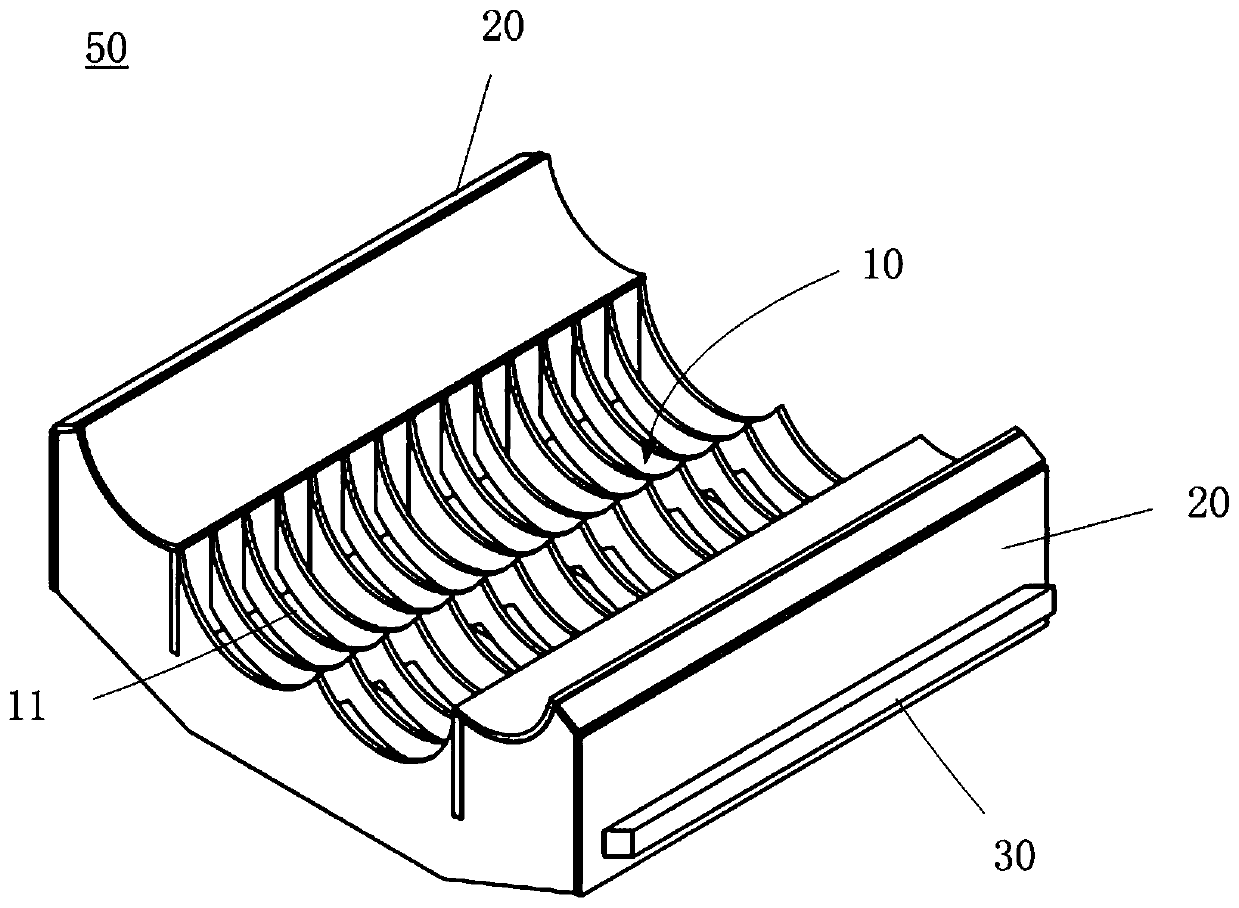

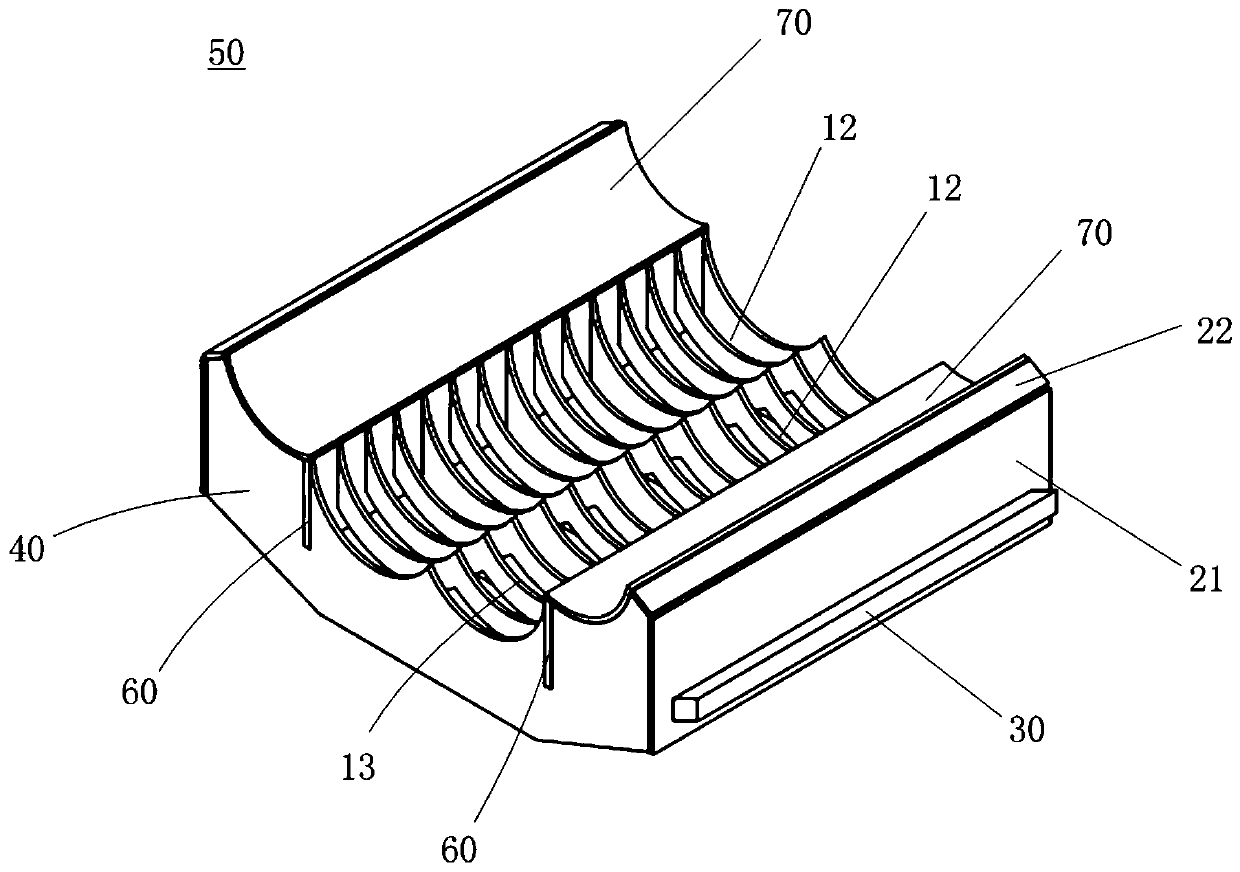

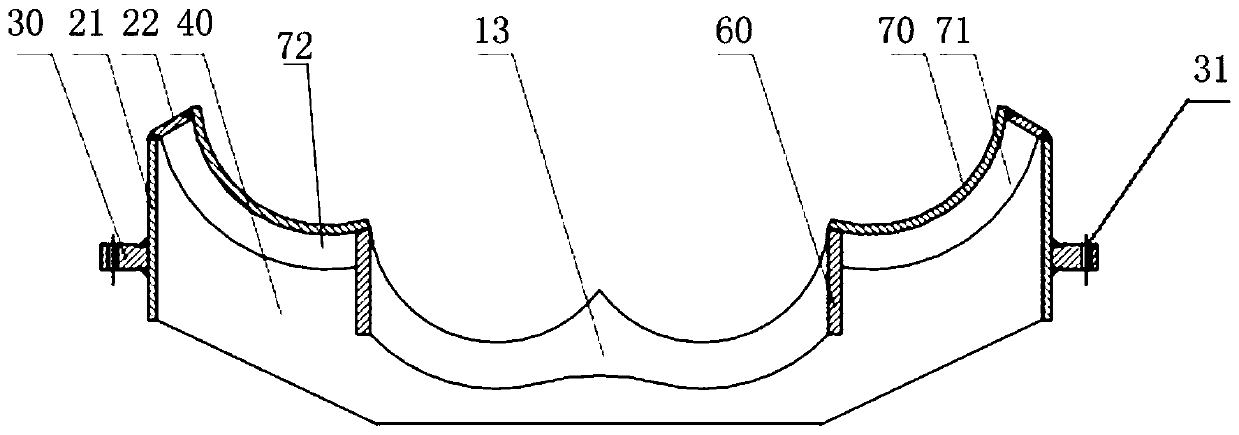

[0021] See attached Figure 1 to Figure 4 , Figure 1 to Figure 4 An example shows the main structure of the sieve plate used in the multi-shaft shear crusher provided by the embodiment of the present invention. The multi-shaft shear crusher in the embodiment of the present invention includes a main cutter head and an auxiliary cutter head. The sieve plate 50 includes a sieve plate body 10 , a supporting side plate 20 and a locking plate 30 . The supporting side plates 20 are fixedly connected to the left and right sides of the sieve plate body 10, and the locking plates 30 are fixedly connected to the supporting side plates 20 to fix the sieve plate 50 on the multi-shaft shearing crusher. Wherein, the sieve plate body 10 includes a main sieve portion 11, the main sieve portion 11 includes at least one main rib 12, the main rib 12 includes a plurality of arc-shaped first grids 13, and the plurality of first grids 13 form a comb shape, And the normal line of each first grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com