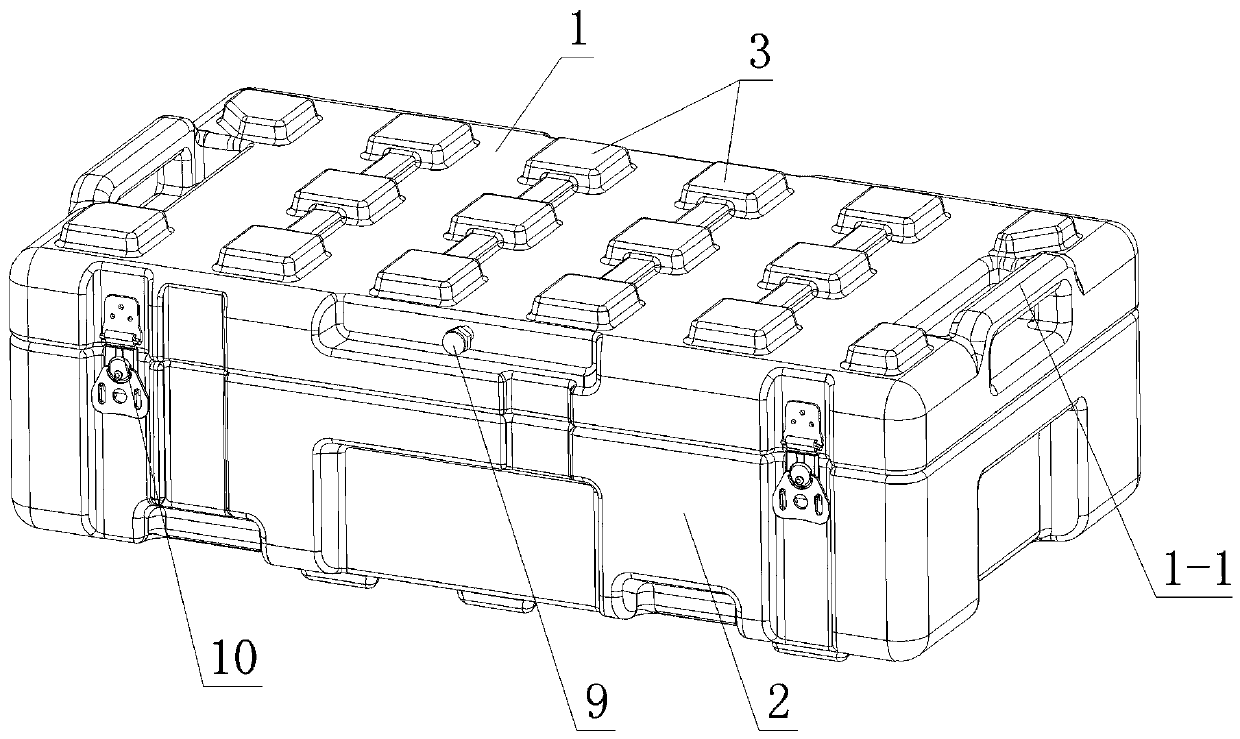

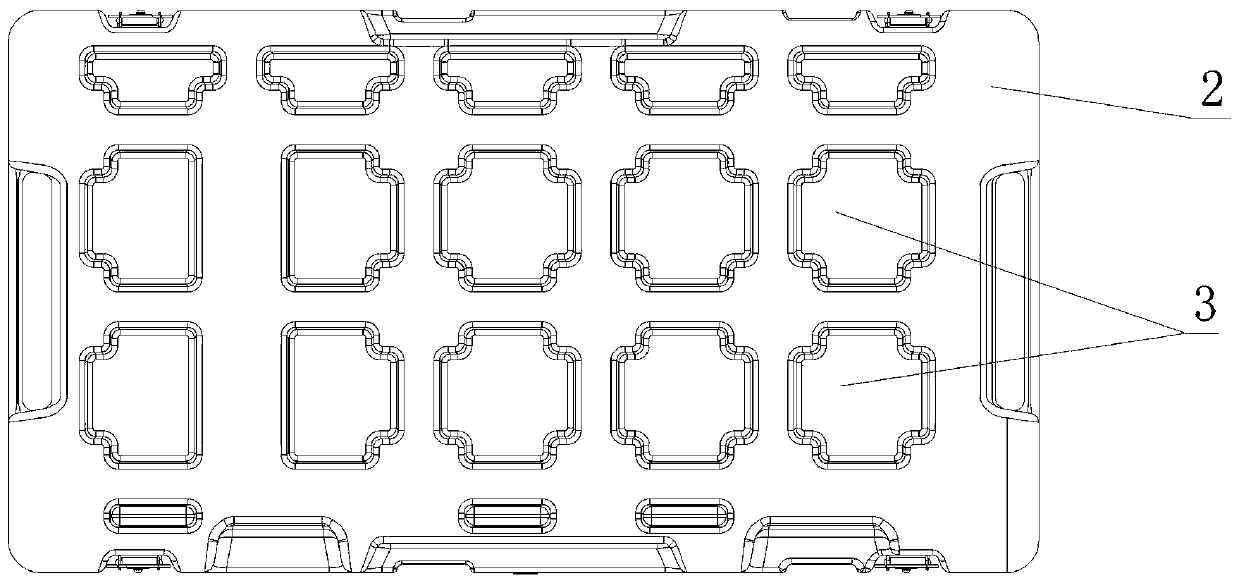

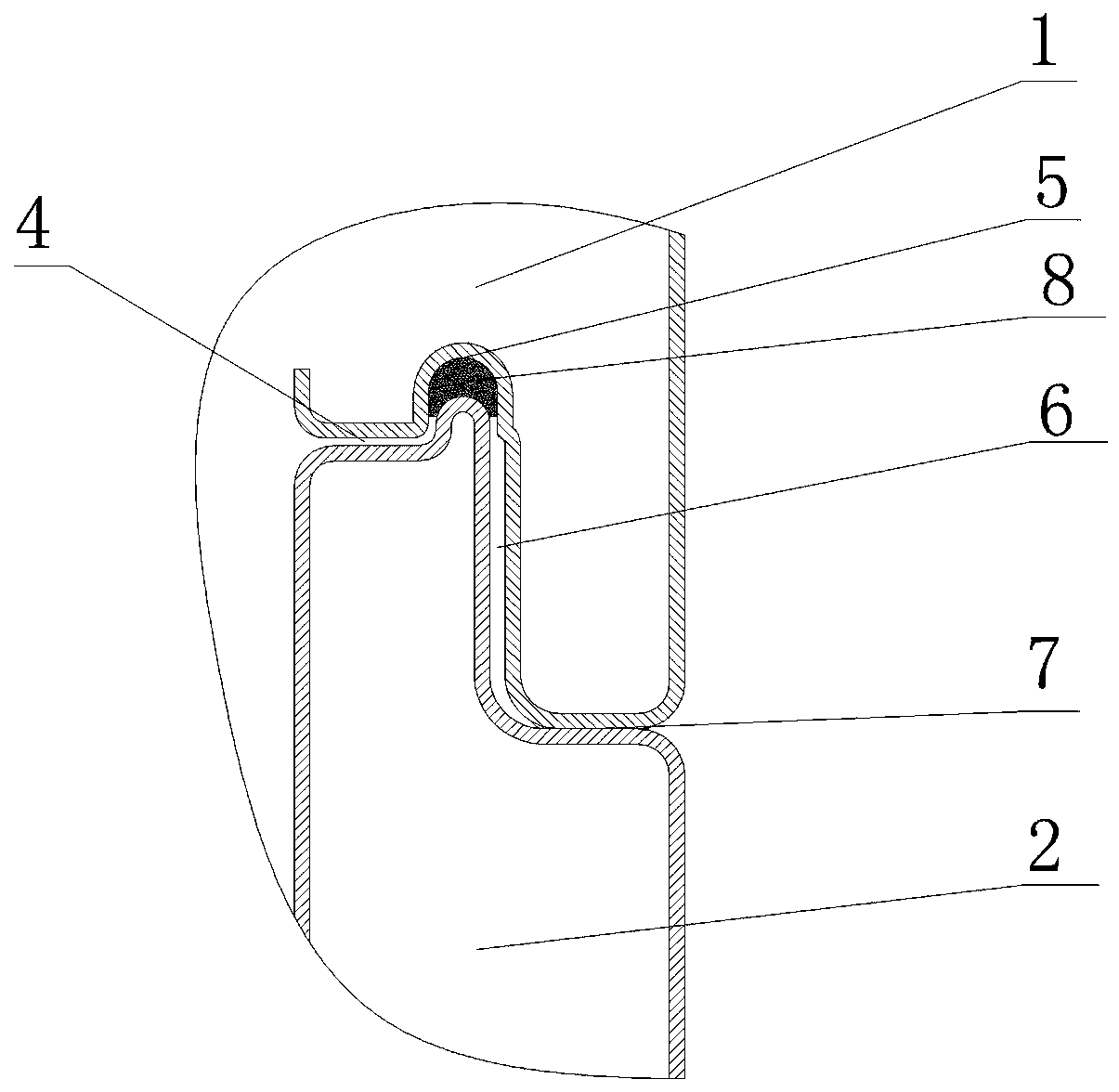

A kind of rotomolding packaging box for airdrop and preparation method thereof

A packing box and rotomolding technology, which is applied in the direction of packaging, transportation and packaging, container handles, etc., to achieve the effect of improving impact resistance and strength, high strength, and good product toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment one, weigh each polyethylene and coupling agent stoste according to the following formula

[0045] 20 parts by weight of polyphenylene ether

[0046] 60 parts by weight of linear low density polyethylene

[0047] 60 parts by weight of low-density polyethylene

[0048] 60 parts by weight of high-density polyethylene

[0049] 20 parts by weight of medium density metallocene polyethylene

[0050] 3 parts by weight of coupling agent;

[0051] Among them, PPO ah60 of Mitsubishi Engineering Plastics is used for polyphenylene ether, the density is 1.06g / cm3, and the melt mass flow rate is 8.1g / 10min; LLDPE7042 produced by Maoming Petrochemical Company is used for linear low density polyethylene, and the density is 0.92g / cm 3 , under the test conditions of 190°C-2.16Kg, the melt mass flow rate is 2g / 10min. The low-density polyethylene is LDPE2420H produced by Maoming Petrochemical Company, with a density of 0.923g / cm 3 , under the test conditions of 190°C-2.16K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com