High-molecular kitchen and bath plate and preparation method thereof

A polymer, kitchen and bathroom technology, applied in the field of preparation of kitchen and bathroom products, can solve the problems of high pollution, non-environmental protection, high energy consumption, etc., and achieve the effects of good gloss, high color fastness, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

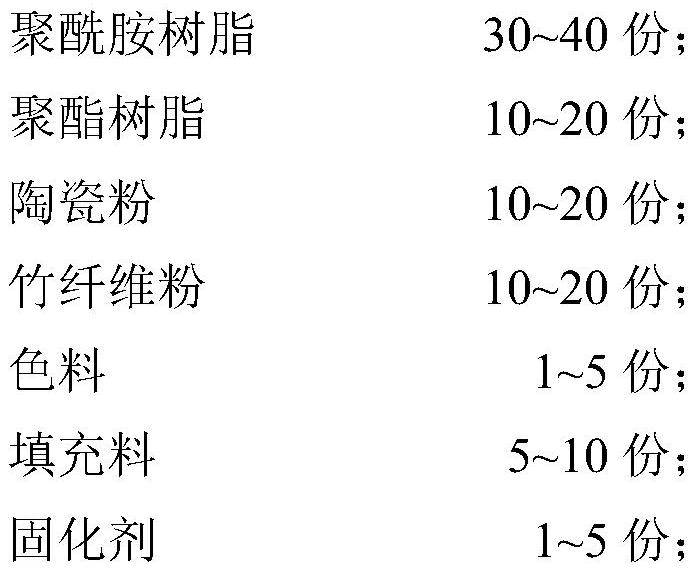

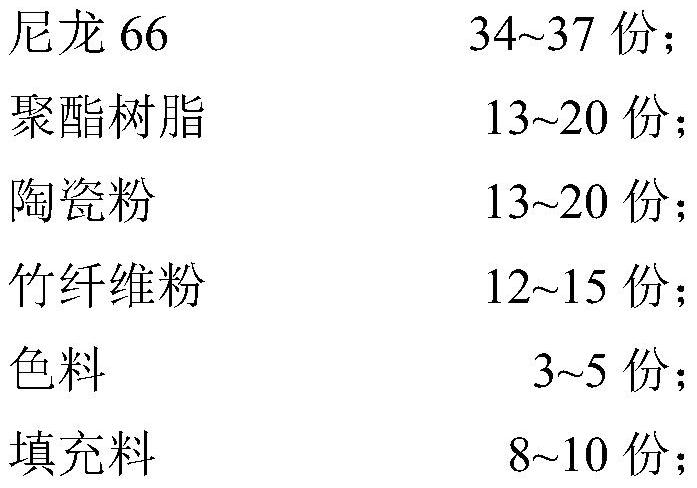

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of polymer raw materials

[0029] 34 parts of relative molecular weight are 20000 and particle size is 170 mesh polyamide resins (nylon 66), 20 parts of relative molecular weight are 10000 and particle size is 170 mesh polyester resins, 15 parts of X7R ceramic powder, 12 parts of bamboo carbon fiber powder, 13 parts 1 part of new medium gray material, 10 parts of pearl powder and 5 parts of aliphatic amine are mixed, and put into a container for full stirring and fusion to obtain a polymer mixture.

[0030] 2. Preparation of polymer kitchen and bathroom boards

[0031] (1) Put the polymer mixture into a high-frequency machine, and perform high-temperature microwave heating to obtain a glue-packed product in the form of flour dough; the temperature of high-temperature microwave heating is 100°C, the time is 6h, and the microwave frequency is 915MHz.

[0032] (2) Fill the plastic package into the customized kitchen and bathroom mold, then put the filled cu...

Embodiment 2

[0035] 1. Preparation of polymer raw materials

[0036] 37 parts of relative molecular weight is 20000 and particle size is 170 mesh polyamide resin (nylon 66), 20 parts of relative molecular weight is 10000 and particle size is 170 mesh polyester resin, 13 parts of X7R ceramic powder, 15 parts of bamboo carbon fiber powder, 13 parts 1 part of ivory white material, 10 parts of rock, and 5 parts of polyisocyanate are mixed, and put into a container for full stirring and fusion to obtain a polymer mixture.

[0037] 2. Preparation of polymer kitchen and bathroom boards

[0038] (1) Put the polymer mixture into a high-frequency machine, and perform high-temperature microwave heating to obtain a glue-packed product in the form of flour dough; the temperature of high-temperature microwave heating is 80°C, the time is 4h, and the microwave frequency is 915MHz.

[0039] (2) Fill the plastic package into the customized kitchen and bathroom mold, then put the filled customized kitchen ...

Embodiment 3

[0042] 1. Preparation of polymer raw materials

[0043] 40 parts of relative molecular weight is 20000 and particle size is 170 mesh polyamide resin (nylon 66), 13 parts of relative molecular weight is 10000 and particle size is 170 mesh polyester resin, 20 parts of X7R ceramic powder, 15 parts of bamboo pulp fiber powder, 13 parts of peacock blue pigment, 8 parts of mica powder, and 2 parts of polyamide are mixed, and put into a container for full stirring and fusion to obtain a polymer mixture.

[0044] 2. Preparation of polymer kitchen and bathroom boards

[0045] (1) Put the polymer mixture into a high-frequency machine, and perform high-temperature microwave heating to obtain a glue-packed product in the form of flour dough; the temperature of high-temperature microwave heating is 110°C, the time is 8h, and the microwave frequency is 915MHz.

[0046] (2) Fill the plastic package into the customized kitchen and bathroom mold, then put the filled customized kitchen and bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com