Welding method, welding device and welding seam grinding device for repairing sheet metal bends

A welding method and a technology of a welding device, which are applied in the field of sheet metal repair, can solve problems such as inability to repair well, and the inability to weld small metal sheets on large metal sheets, etc., and achieve simple and efficient repair procedures, compact structure, The effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

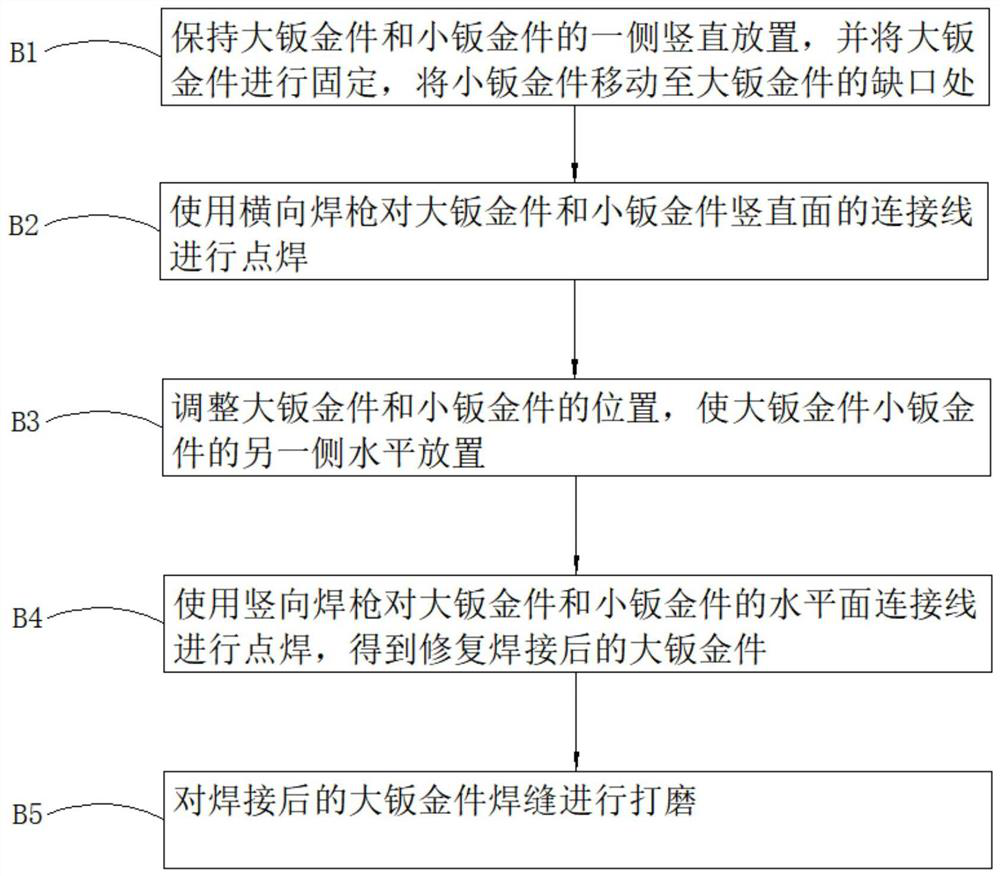

[0051] refer to figure 1 , a welding method for repairing gaps in sheet metal bends, comprising the following steps:

[0052] B1: Keep one side of the large sheet metal part and the small sheet metal part placed vertically, fix the large sheet metal part, and move the small sheet metal part to the gap of the large sheet metal part;

[0053] B2: Use a horizontal welding torch to spot weld the connection line between the vertical surface of the large sheet metal part and the small sheet metal part;

[0054] B3: Adjust the position of the large sheet metal part and the small sheet metal part so that the other side of the large sheet metal part and the small sheet metal part is placed horizontally;

[0055] B4: Use a vertical welding torch to spot-weld the horizontal connecting lines of large sheet metal parts and small sheet metal parts to obtain repaired large sheet metal parts after welding;

[0056] B5: Grinding the weld seam of large sheet metal parts after welding.

[005...

Embodiment 2

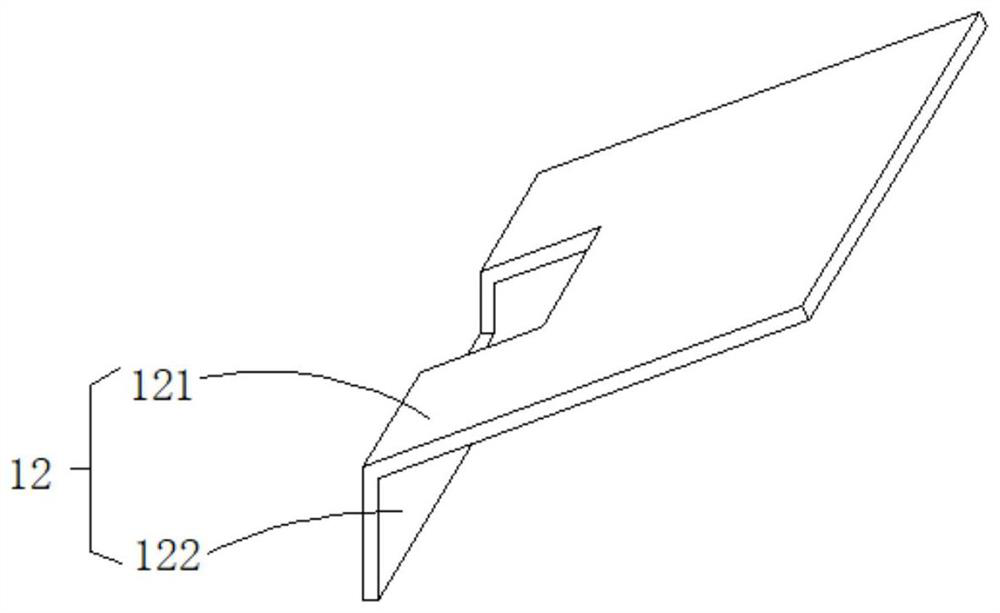

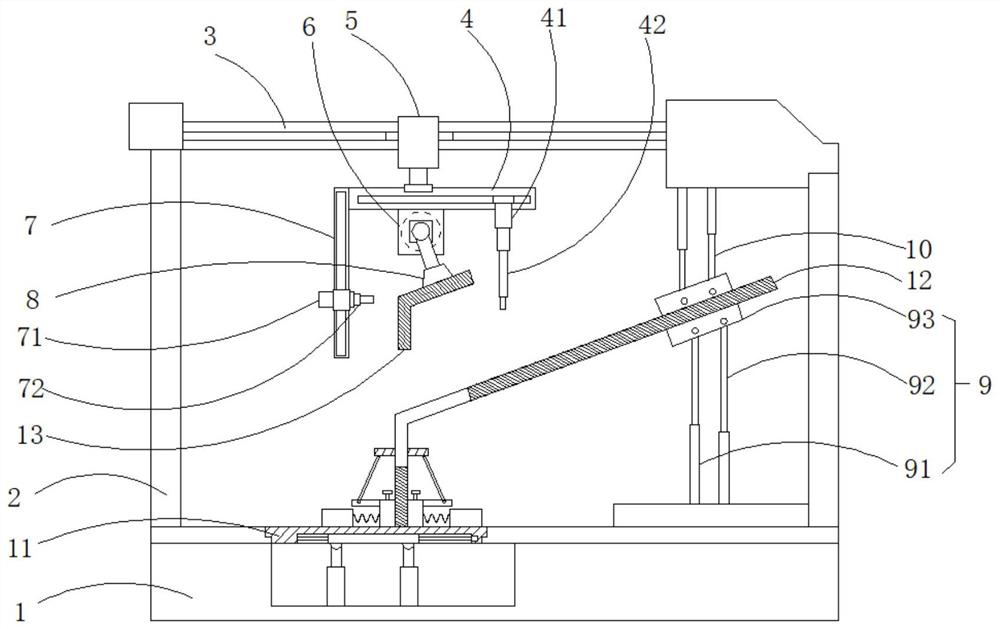

[0059] refer to image 3 The welding device in this embodiment is used for welding small sheet metal parts with gaps, and includes a base 1, a vertical column 2 and a beam 3, and the base 1, the vertical column 2 and the beam 3 form a space in which a welding assembly is arranged, so The welding assembly includes installing a vertical welding torch 42, a horizontal welding torch 72, a suction nozzle 8 for absorbing small sheet metal parts 13, a horizontal fixing seat and a vertical fixing seat 11 for fixing large sheet metal parts.

[0060] Specifically, the vertical welding torch 42, the horizontal welding torch 72 and the suction nozzle 8 are all installed on the horizontal mounting bracket 4, and the horizontal mounting bracket 4 is located below the crossbeam 3, and a chute in the X-axis direction is set on the crossbeam 3, The chute is provided with a Y-axis direction sliding rod, and the Y-axis direction sliding rod is provided with a lift cylinder 5 that is slidably con...

Embodiment 3

[0076] refer to Figure 7 and Figure 8 , the upper end of each set of clamping blocks 113 in this embodiment is provided with handles 1111, the two ends of the handles 1111 are respectively hinged to the upper ends of the connecting rods 1110, and the lower ends of each of the connecting rods 1110 are respectively hinged to different clamping Block 113, press the handle 1110, the spring 114 can be compressed, and the two clamping blocks 113 are far away, so that the vertical side 122 of the large sheet metal plate 12 can be conveniently put in and taken out between the clamping blocks 113.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com