Full-automatic box gluing and folding machine

A folding box machine, fully automatic technology, applied in container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve problems such as increasing production costs, inability to fold and form cardboard of different widths and sizes, etc., to improve practicability, The effect of improving the efficiency of adjustment and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings.

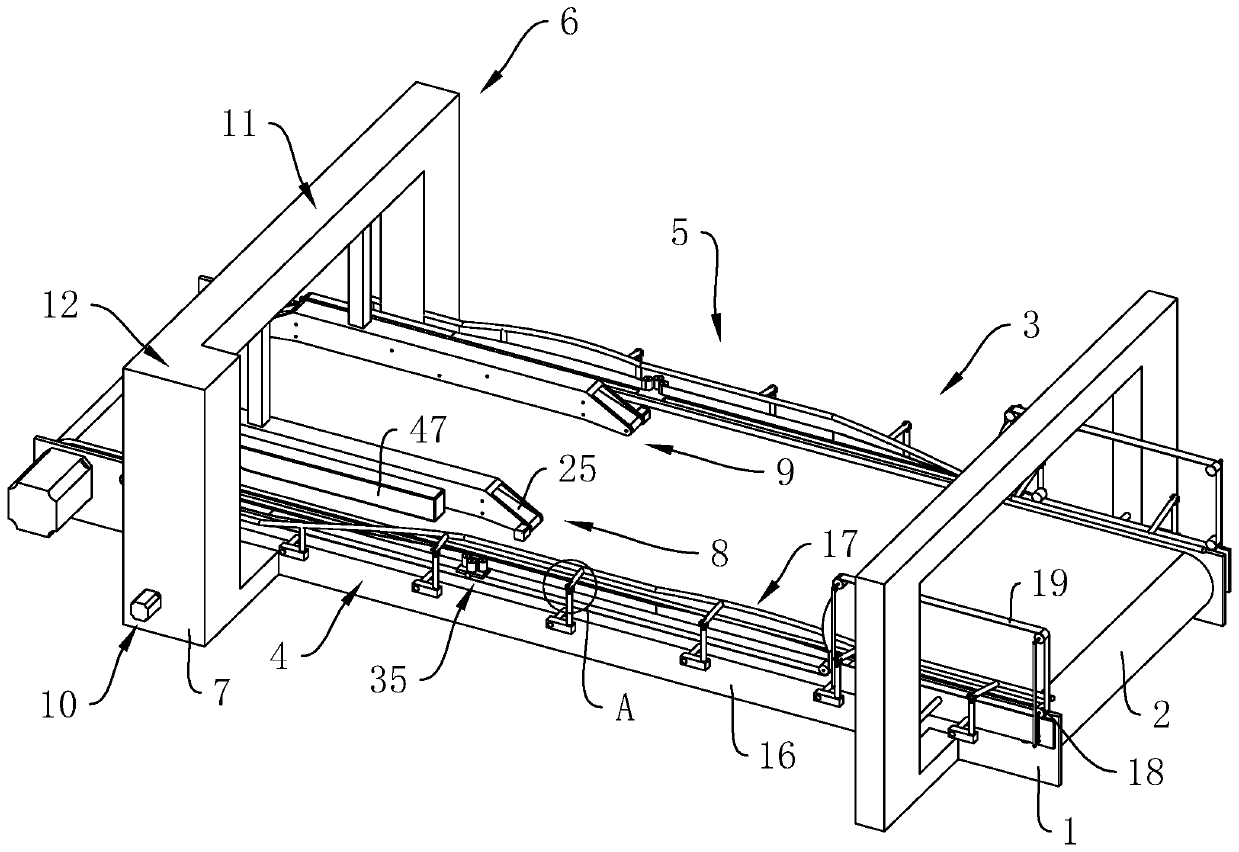

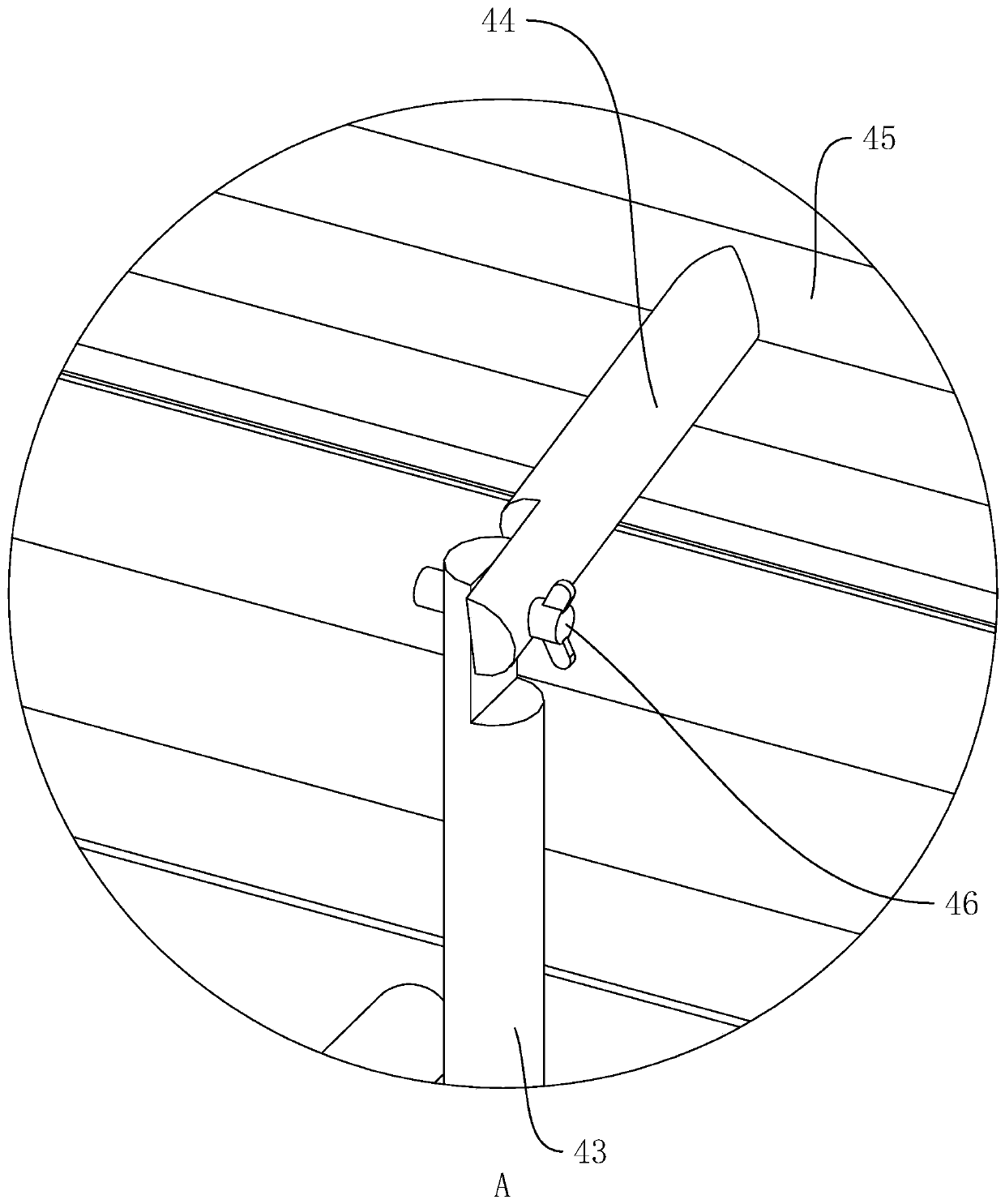

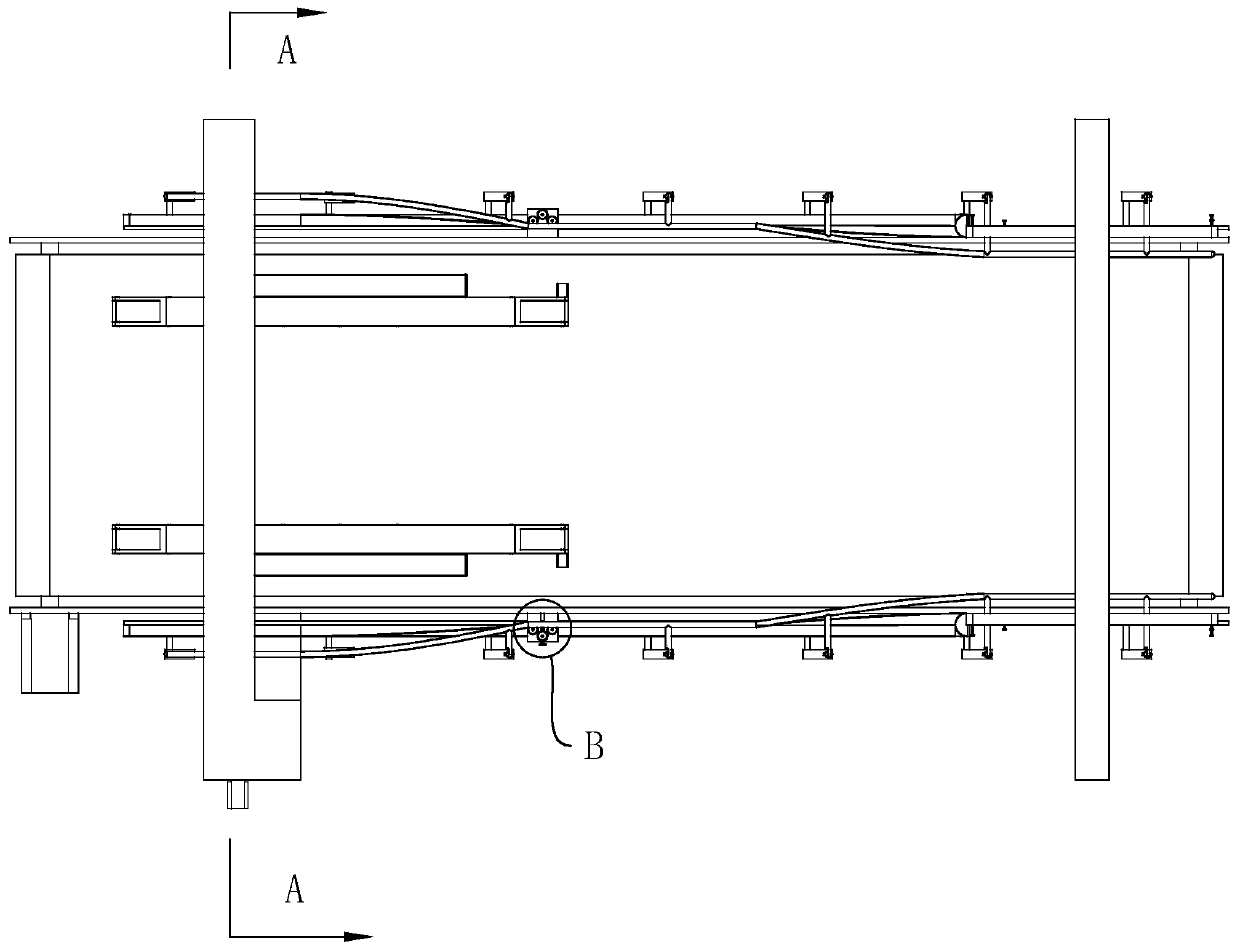

[0034] like figure 1 and figure 2 As shown, a fully automatic folder gluing and folding machine includes a frame 1, and a conveyor belt 2 is arranged on the frame 1, and the conveyor belt 2 is used to drive the folding box cardboard to move forward. The frame 1 is provided with a paper feeding device, a gluing device, a folding line device 3, a forming device, a pressing device and a hot pressing device in sequence along the advancing direction of the folding box cardboard. The folding line device 3 includes a first folding line component 4 , a second folding line component 5 and a pressing component 6 . The first folding line assembly 4 is arranged on one side of the frame 1 along the width direction, the second folding line assembly 5 is arranged on the other side of the frame 1 along the width direction, and the pressing member 6 includes a bracket 7 fixe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap