A screen printing mold and screen printing machine

A mold and screen printing technology, applied in the field of screen printing molds and screen printing machines, can solve the problems of conflict generation efficiency, difficult to control ink flow, blade pressure, process adaptability and poor printing quality, etc., to reduce processing difficulty, ensure flexibility and good sealing Contact, achieve precise control of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The main purpose of the present invention is to provide a screen printing mold and a screen printing machine which can improve the printing quality and efficiency of the convex surface of the arched workpiece.

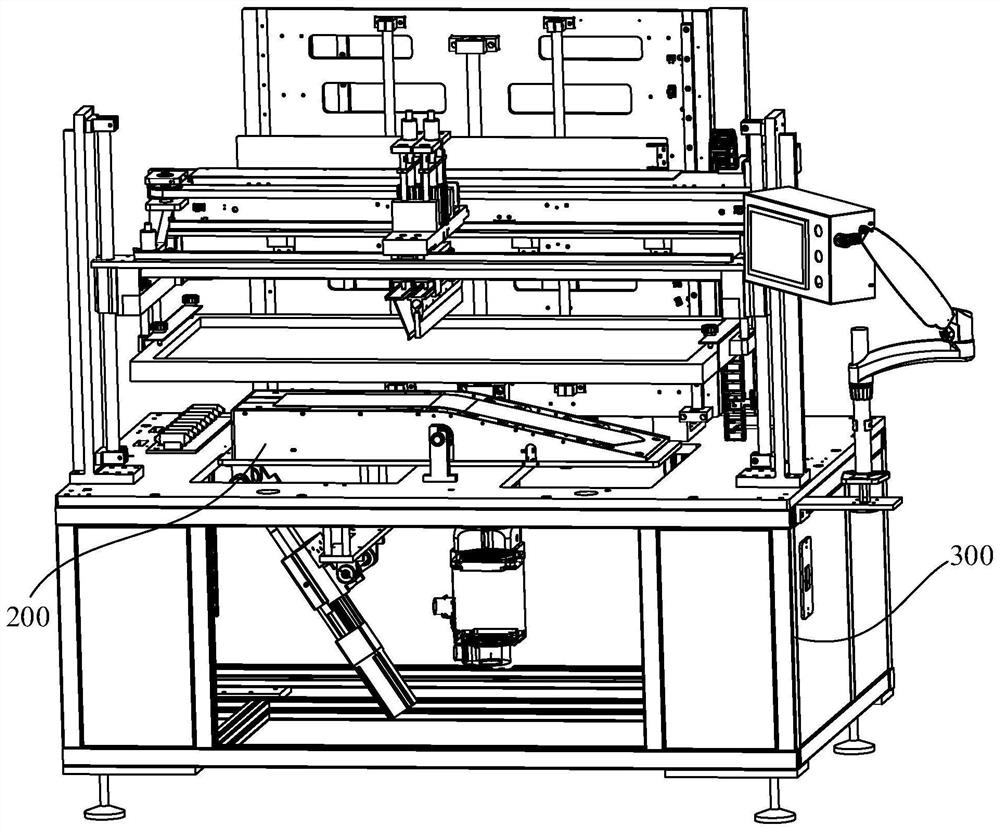

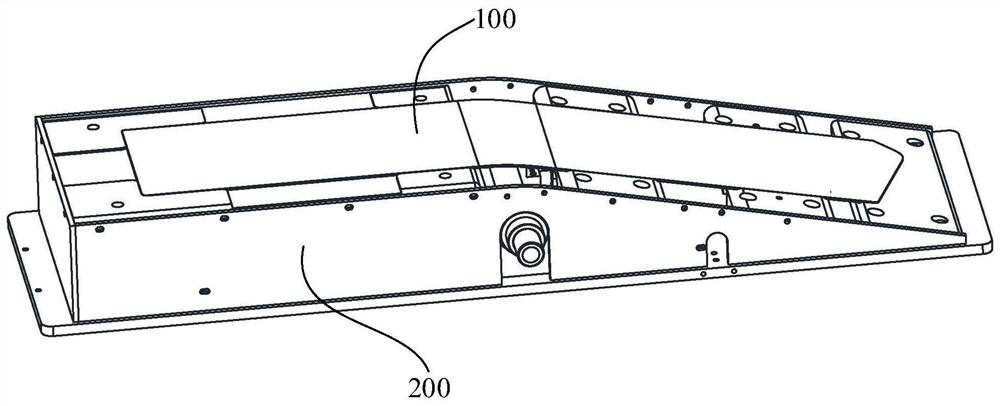

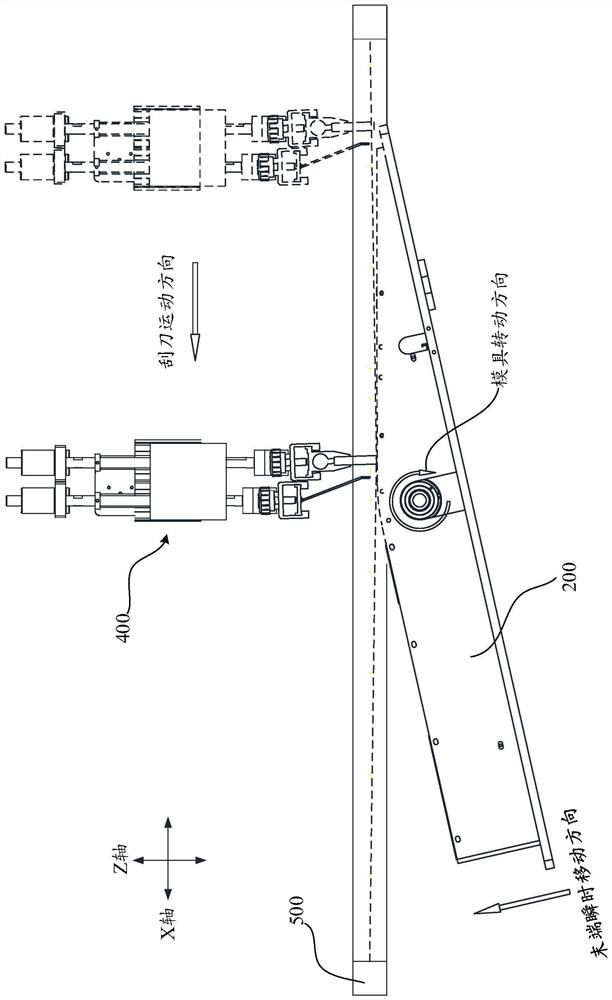

[0061] Please refer to Figure 1-Figure 4 In order to realize the industrial printing of the convex surface of the arched workpiece 100, a corresponding screen printing machine can be provided. The convex surface of the arched workpiece includes a first plane, a second plane, and a curved surface that is smoothly connected with the first plane and the second plane respectively; The screen printing machine includes a screen printing mold 200, a frame 300, a scraper mechanism 400, a screen printing screen 500 and a plurality of driving mechanisms for driving movable parts to move.

[0062] In this screen printer, please refer further to Figure 5 , the top of the screen printing mold 200 forms a first mold cavity 21 and a second mold cavity 22 along the X axis, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com