A kind of non-oriented electrical steel under low magnetic field and its production method

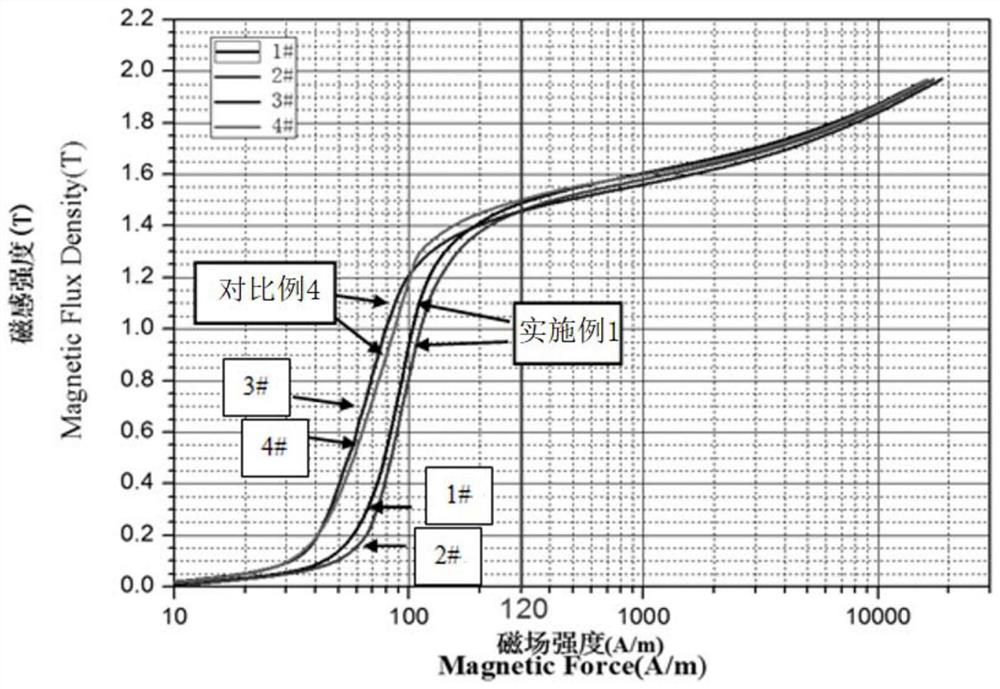

A technology of oriented electrical steel and low magnetic field, which is applied in the field of non-oriented electrical steel and its production, can solve the problems of poor magnetization performance of non-oriented electrical steel, and achieve the effect of benefiting magnetization ability, prolonging the holding time and reducing the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

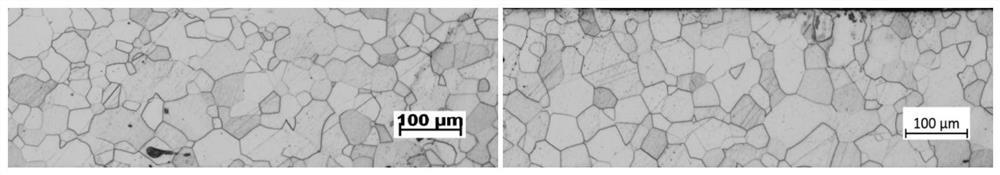

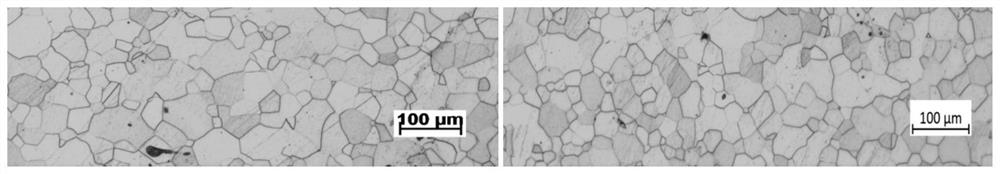

[0048] In this implementation, a non-oriented electrical steel under low magnetic field includes the following components in weight percentage: C: 0.0019%, Si: 2.9%, Mn: 0.25%, P: 0.003%, Als: 0.85%, S : 0.001%, N: 0.0007%, Ti: 0.0015%, the rest is iron and unavoidable impurities; the production method of the non-oriented electrical steel under the low magnetic field is as follows:

[0049] Preparation of slab: adding molten iron to the RH furnace for refining and alloying treatment, adding various alloying elements according to the design requirements of the components; continuously casting the molten steel refined in the RH furnace into a slab with a thickness of 220mm;

[0050] Slab heating: the slab after continuous casting is cooled and then enters the heating furnace, the temperature of the heating furnace is 1180°C, and the time is 210min;

[0051] Hot-rolled coiling: the heated slab is rough-rolled to 34mm in 3 passes, finished in 7 passes to 2.0mm in thickness, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com