A flexible male rotation transmission device and a coating machine cavity with the device

A conveying device and a technology of public rotation, which is applied in the field of flexible public rotation transmission device and coating machine cavity, can solve the problems of excessive structure and affect the installation of the overall coating machine, etc., and achieve the effect of simple operation and small structure volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

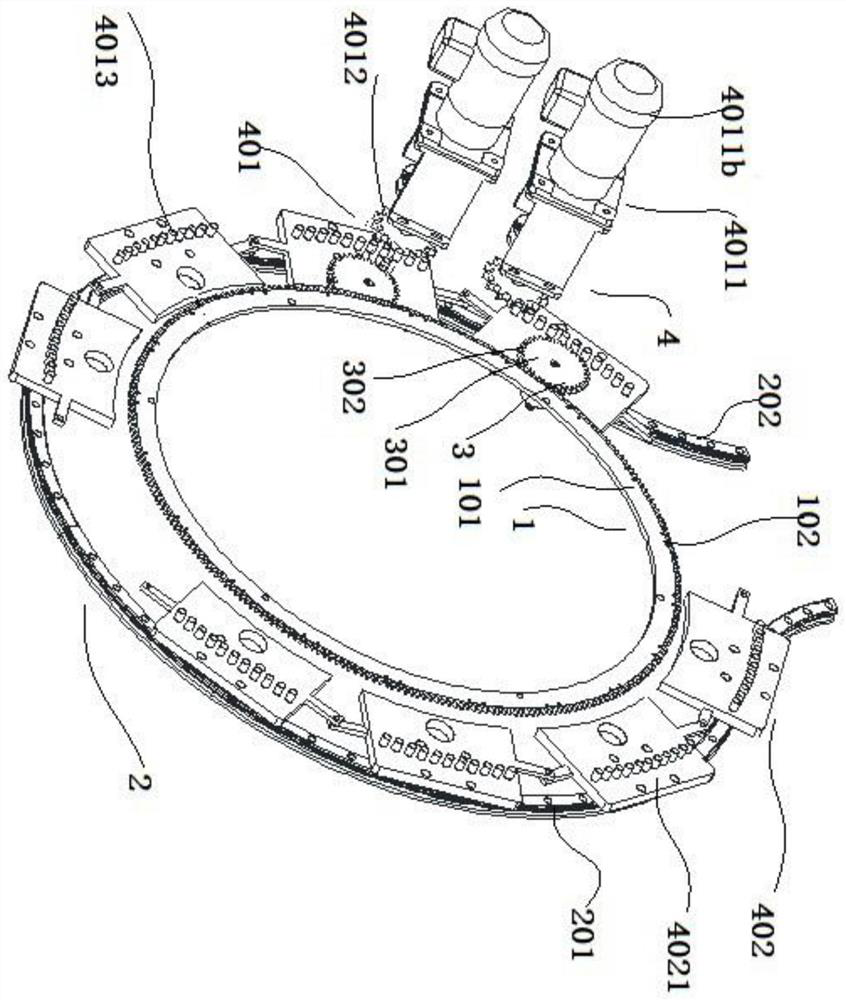

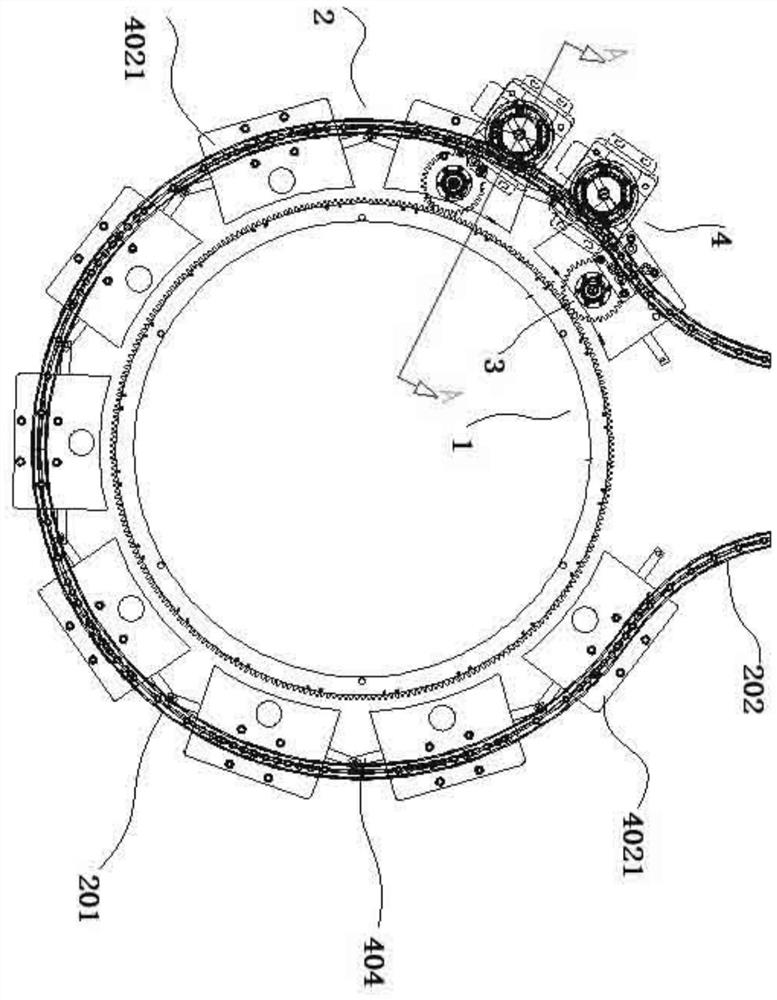

[0036] A flexible male rotation transmission device A, such as Figure 1 to Figure 5 As shown, it includes: a fixed toothed plate 1; a flexible track 2, the flexible track 2 is arranged on the outer ring of the fixed toothed plate 1, the fixed track can be designed in advance according to the working track, or it can be designed as a variable track during operation A plurality of self-rotating wheel discs 3, the self-rotating wheel discs 3 are installed between the flexible track 2 and the fixed tooth plate 1, and are in contact with the fixed tooth plate 1, which can generate frictional force ; drive mechanism 4, the drive mechanism is mounted on the flexible track 2 and is connected with the autorotation wheel 3, and the autorotation wheel 3 is driven by the drive mechanism 4 along the flexible track 2 At the same time, due to the interaction force between the self-rotating wheel 3 and the fixed tooth plate 1, the self-rotating wheel 3 also rotates while moving along the fle...

Embodiment 2

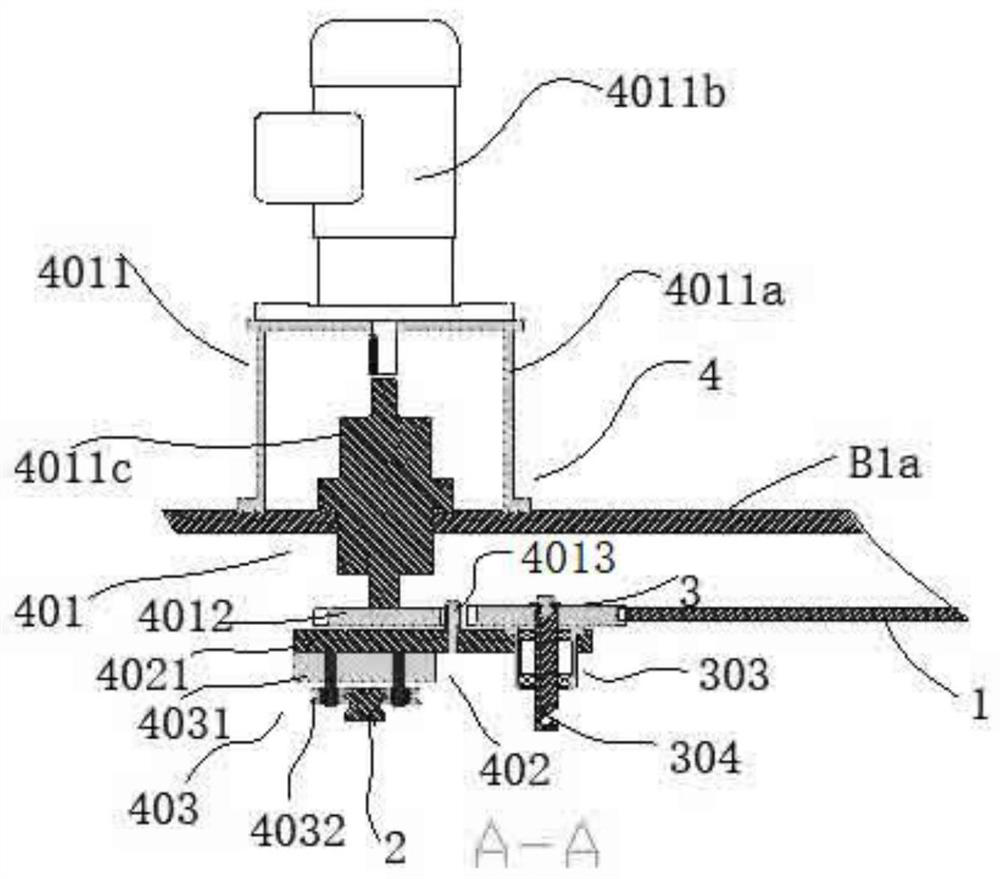

[0043] A single cavity B of a coating machine, such as Figure 4 to Figure 6 As shown, it includes: a cavity body B1 and a cavity door (not shown in the figure), the cavity body B1 includes a cavity body top side B1a and a cavity body side B1b surrounding the cavity body top side B1a, the cavity body The side B1b is provided with an opening B2, the cavity door is installed at the opening B2 of the cavity body, and the top side B1a of the cavity body is installed with the flexible male rotation upper conveying device A of Example 1. In this embodiment, the top side of the cavity body is B1a is provided with a mounting hole for the transmission device, the power motor 4011b and the motor mounting seat 4011a are installed on the outside of the top side of the cavity body B1a, the magnetic fluid 4011c is installed in the motor mounting seat 4011a and is connected to the power sprocket 4012 vacuum-tightly through the mounting hole of the transmission device , the power sprocket 401...

Embodiment 3

[0046] A multi-cavity coating machine, such as Figure 4 to Figure 7 As shown, the multi-chamber body of the coating machine is formed by splicing a plurality of single-chamber bodies B of the coating machine through a vacuum isolation valve C. In this embodiment, the vacuum isolation valve C used is a plug-in valve, wherein each coating machine The single cavity includes: a cavity body B1 and a cavity door (not shown in the figure). The cavity body B1 includes a cavity body top side B1a and a cavity body side surface B1b surrounding the cavity body top side B1a. The cavity body The side B1b is symmetrically provided with two openings B2, the cavity door is installed at the opening B2 of the cavity body, the vacuum isolation valve C is spliced at the cavity door, and the top side B1a of the cavity body is installed by the above-mentioned flexible male rotation transmission device A. Refer to Example 2 for the installation method of the flexible male-rotation upper conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com