Water-seepage-preventing construction method for garage roof

A construction method and anti-seepage technology, which is applied in the construction field of garage roof anti-seepage, can solve the problems of large disturbance of the floor, poor safety protection performance, delayed construction process, etc., to eliminate water seepage, avoid unsafe factors, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

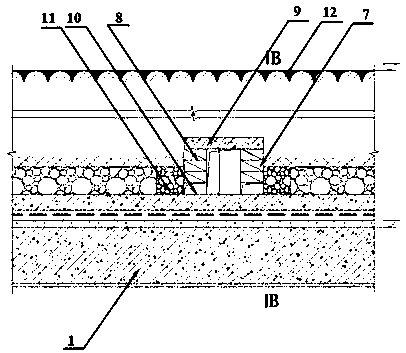

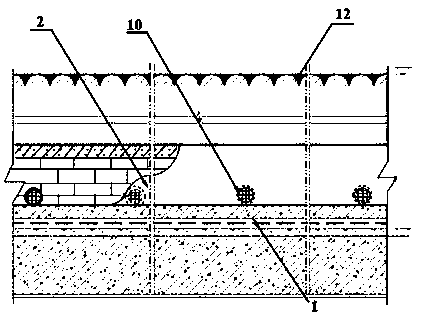

[0034] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

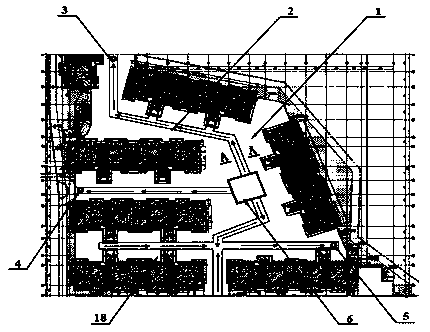

[0035] This example: see Figure 1 to Figure 5 , a construction method for anti-seepage of a garage roof, comprising the following construction steps:

[0036] Step 1: Carry out measurement and setting out on the roof 1 of the completed garage, and determine the layout of the blind ditch;

[0037] Step 2: After the surface layer of the garage roof 1 is waterproofed, the blind ditch 2 cushion layer is laid on the surface layer of the garage roof 1, so that the cushion layer has a certain slope along the water collection direction according to the blind ditch layout line;

[0038] Step 3: Use solid bricks 7 on the cushion layer of blind ditch 2 to form a blind ditch network 2 composed of multiple blind ditches according to the layout of blind ditch, and set a water drop hole 14 at the end of blind ditch 2 along the water collection direction according to process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com