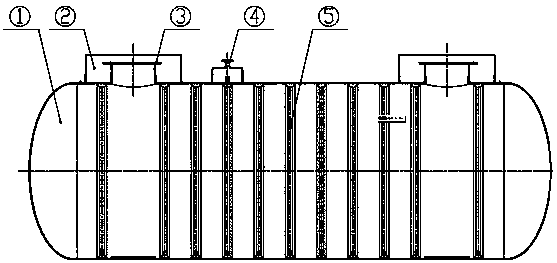

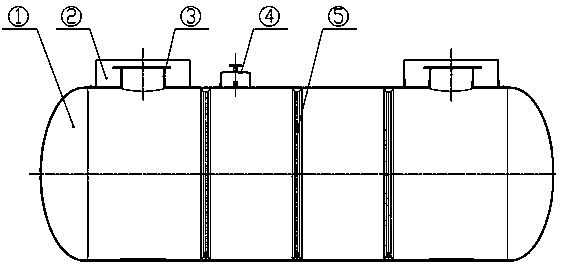

Safety solid plasticization construction process for fiber reinforced plastic dual-layer lining of underground storage tank

A fiber-reinforced plastic, double-layer lining technology, applied in the direction of container, packaging, transportation and packaging, can solve the problems of complicated engineering, long construction period, high investment and reconstruction cost, etc., to reduce investment cost, shorten construction period, avoid overall The effect of ground breaking construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

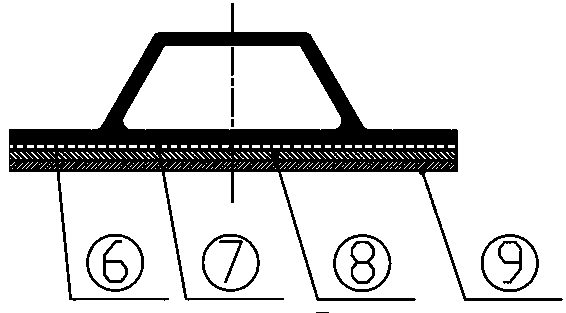

[0043] A safe plastic-fixing construction technology for fiber-reinforced plastic double-layer lining of underground storage tanks, the specific construction process includes:

[0044] Step 1: Degreasing, derusting, phosphating and passivating the surface of the inner tank body

[0045] Use degreasing and derusting agents to clean up the oil, rust and other harmful substances attached to the inner wall of the storage tank until the inner surface of the tank is exposed to the original color of the metal, and at the same time, phosphating and passivating the metal surface to prevent further corrosion; The reaction process of degreasing and derusting agent is a gasification process, and only residues are left after the reaction; At the same time of operation, forced air induction must be implemented in the tank, and the waste gas and other toxic gases generated during the degreasing and derusting process must be discharged out of the tank in time, so as to ensure the safety of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com