Flatness detection bench

A technology of flatness detection and flatness, which is applied in the direction of measuring devices and instruments, can solve the problems that affect the production efficiency of flat top chains, low precision, and long time consumption, and achieve strong practicability, improve efficiency, and avoid measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

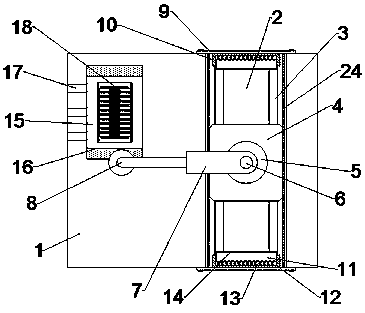

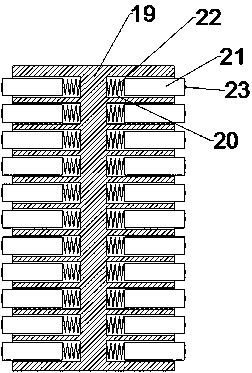

[0019] see figure 1 and figure 2 , a flatness detection platform, including a base 1, a chute 2, a track 3, a slider 4, a rotating connector 5, a column 6, a connecting rod 7 and a flatness detector 8, and the right side of the upper end surface of the base 1 is set There is the chute 2, the left and right inner walls of the chute 2 are processed with the rails 3, the slider 4 is slid forward and backward in the chute 2, and the upper end of the slider 4 is welded and fixed with the Rotating connector 5, on which the column 6 is rotatably installed, the connecting rod 7 is welded and fixed on the top of the column 6, and the flatness detector 8 is installed on the bolt at the left end of the connecting rod 7 ; The damping sheet 24 is bonded on the track 3, which can provide damping during the sliding process of the slider 4 to ensure a uniform sliding speed and improve detection accuracy, while avoiding damage to the detector due to excessive sliding impact; the front and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com