Equipment fault monitoring and early warning system in building

A technology of equipment failure, monitoring and early warning, applied in the direction of alarm, 3D modeling, image data processing, etc., can solve the problems of equipment life impact, monitoring equipment parameters or abnormal working status, abnormal operating status and parameters, etc., to avoid blindness The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

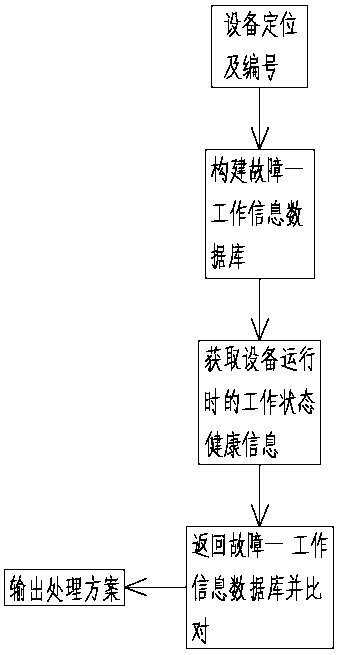

[0039] Such as figure 1 As shown, a building equipment fault monitoring and early warning system, the operation method of the fault monitoring and early warning system is:

[0040] S1. Establish a three-dimensional architectural model of the entire space, and then position and number all equipment in the architectural model;

[0041] S2. Build a fault-working information database of equipment, in which the working state health information of each type of equipment is stored in normal operation, and the corresponding working state health information when different types of faults occur;

[0042] S3. Obtain the working status and health information of each device during operation, compare it with the information in the fault-working information database, and output a corresponding processing plan.

Embodiment 2

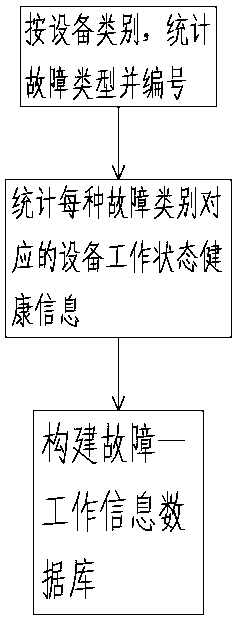

[0044] Such as figure 2 As shown, this embodiment is a detailed description of the fault-work information database of the construction equipment in S2 of Embodiment 1:

[0045]1) According to the equipment category, the fault types are counted, and each fault type is numbered;

[0046] 2) According to the fault category, collect the equipment working status health information corresponding to each fault category, and associate the fault category with the equipment working status health information to form a fault-working information database;

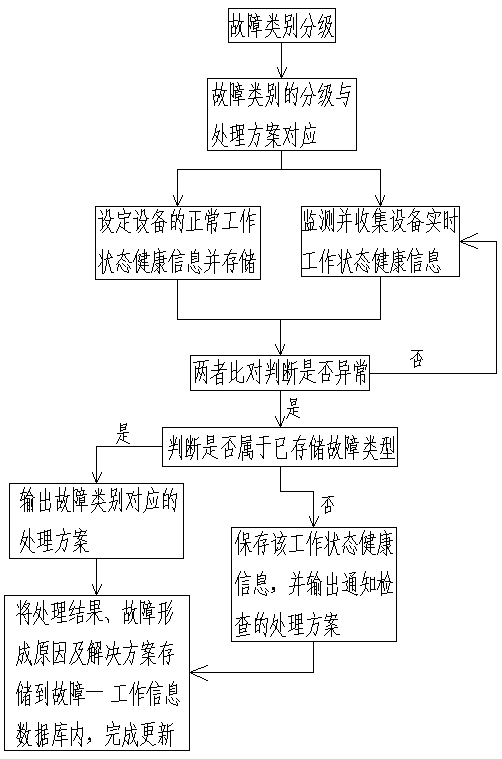

[0047] Such as image 3 As shown, the specific operation of the S3 is:

[0048] 3) According to the severity of the fault category, the equipment is divided into four levels of treatment schemes: alarm reminder, notification inspection, notification maintenance and outage maintenance, and all failure categories are included in the corresponding treatment scheme;

[0049] 4) Set the normal working status health information of each eq...

Embodiment 3

[0062] This embodiment is a specific description of the processing scheme corresponding to the output of S3 described in Embodiment 1:

[0063] 1) Send an alarm message on the system interface, mobile APP or handheld terminal, and output the location of the device, the cause of the alarm, the consequences of continuous deterioration and the corresponding treatment plan;

[0064] 2) Confirm and handle the fault at the fault site, and then add the cause of the fault and the processing process to the fault-work information database through the system interface, mobile APP or handheld terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com