Direct-current circuit breaker transfer branch unit based on IEGT

A DC circuit breaker and transfer branch technology, applied in electrical components, emergency protection circuit devices, etc., can solve the problems of inconvenient maintenance and large valve group size, achieve easy installation and maintenance, ensure uniform distribution, and neutralize improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

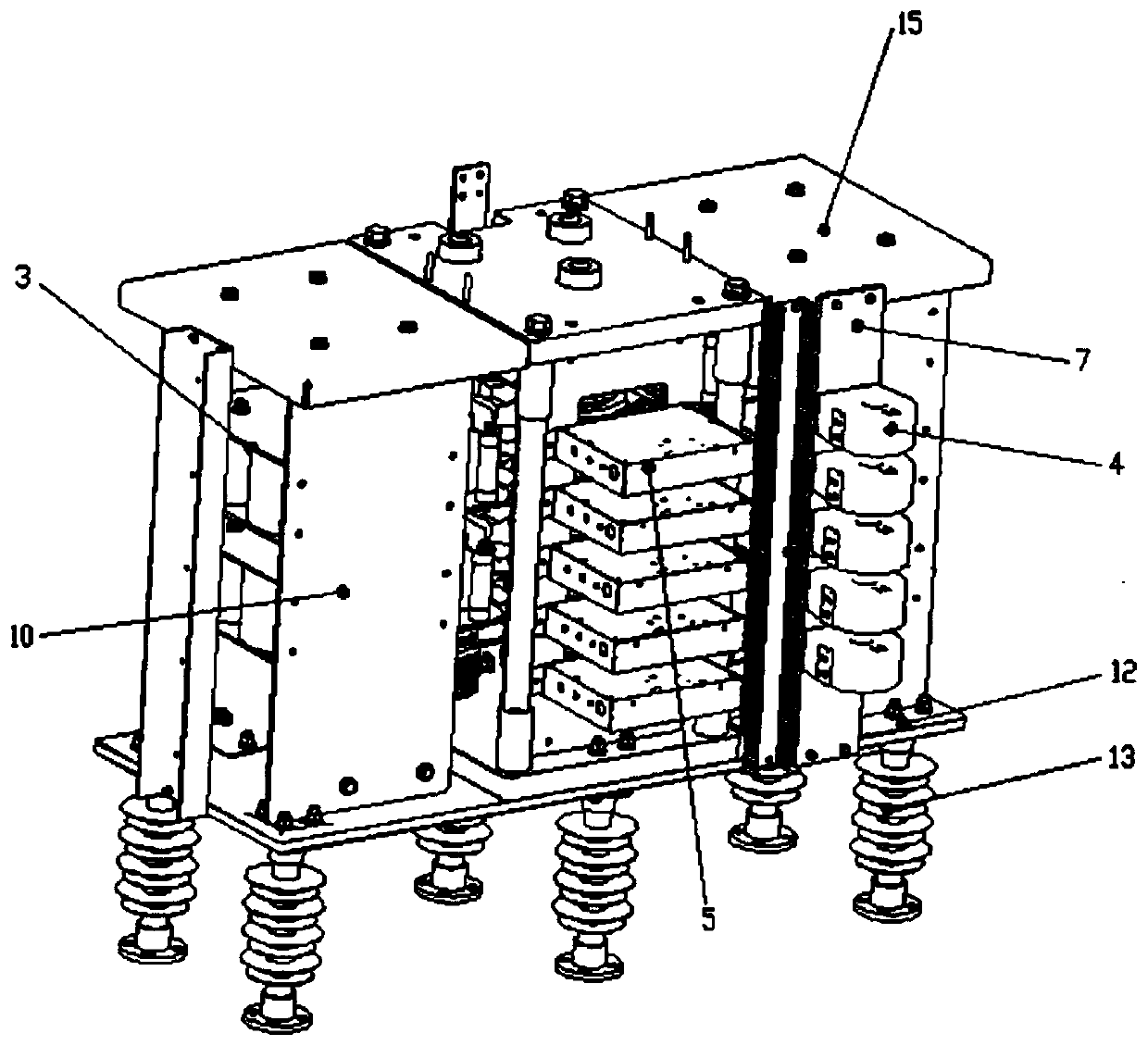

[0029] Such as figure 1 As shown, a DC circuit breaker transfer branch unit based on IEGT includes a valve string crimping mechanism, a plurality of RCM buffer energy consumption units 3 respectively connected to the IEGT devices in the valve string crimping mechanism, and a valve string crimping A plurality of driving boards 5 connected to the IEGT devices in the mechanism and a plurality of energy supply coils 4 respectively connected to the driving boards;

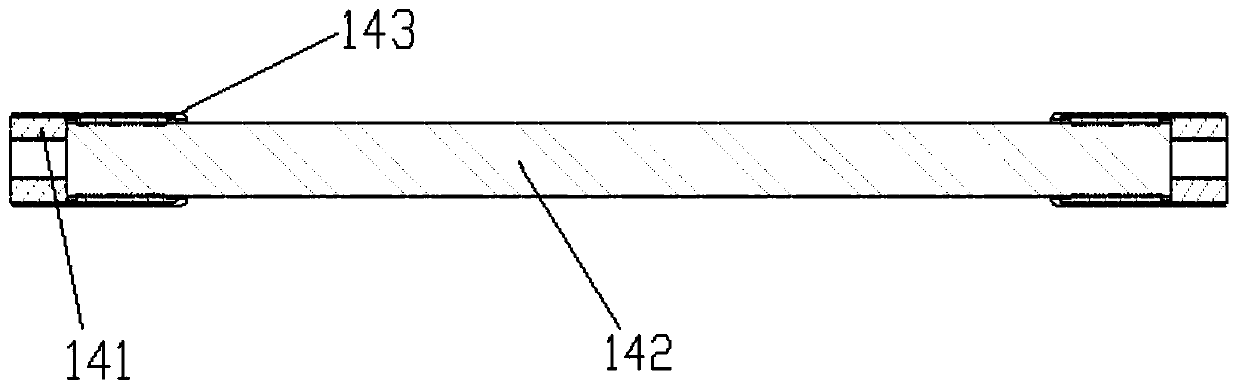

[0030] Such as figure 2 As shown, the valve string crimping mechanism includes: a first pressing plate 6, a second pressing plate, an insulating pull rod, and at least one group of three series valves fixed between the first and second pressing plates (to realize the two-way flow of current ), the insulating pull rod is fixed between the first compression plate 6 and the second compression plate, and the first and second compression plates and the insulating pull rod form a cage frame; further, there are four insulati...

Embodiment 2

[0047] The difference from Embodiment 1 is that the valve string crimping mechanism includes: a first compression plate 6, a second compression plate, an insulating pull rod, and at least one IEGT fixed between the first and second compression plates The crimping unit can realize unidirectional current flow.

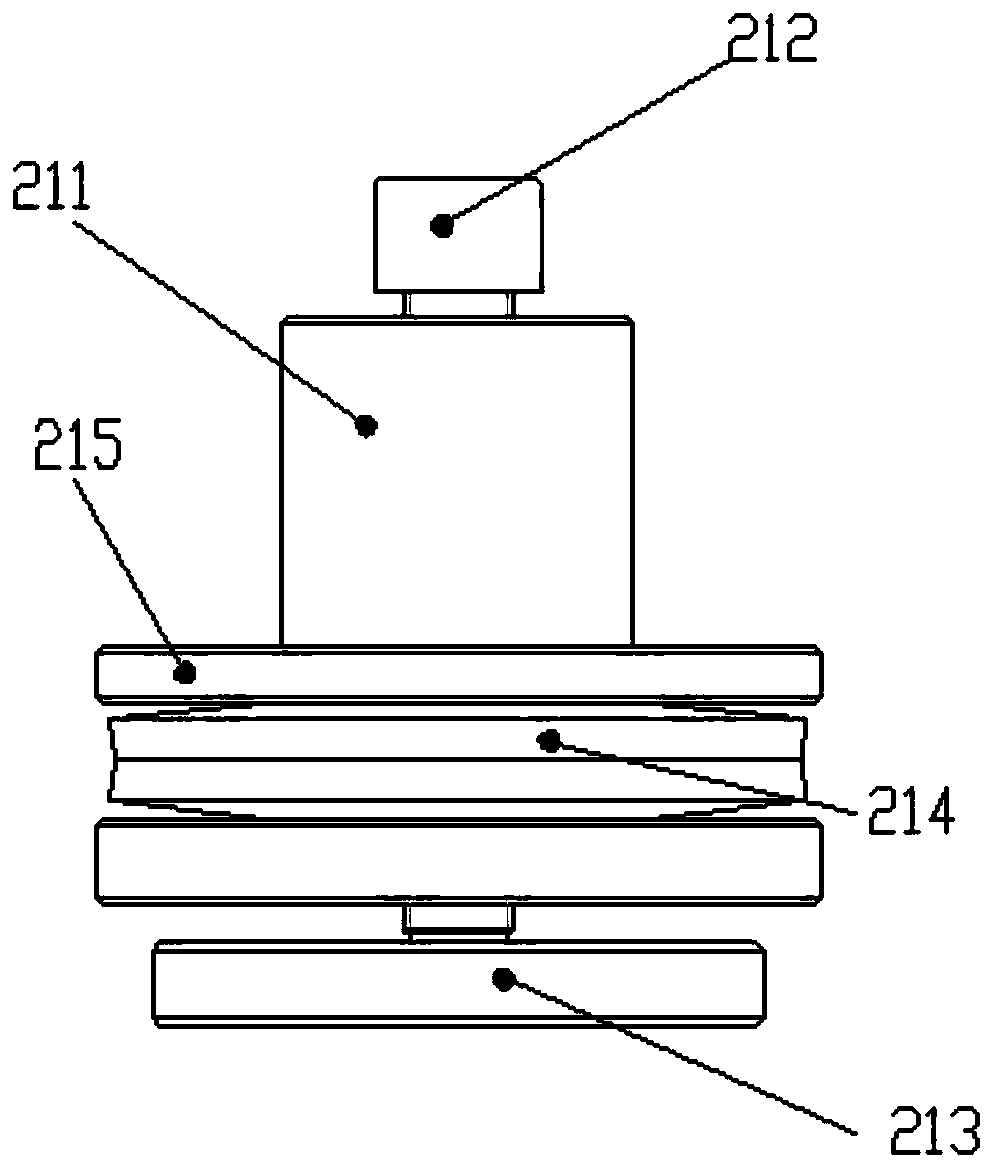

[0048] The specific method of use is: use a torque wrench to tighten the ball stud bolt 212 to generate pressure on the ball socket pressing plate 213, and the press-fitting structure moves up to the disc spring upper plate 215 to contact the first pressing plate 6 to form a limit, and the disc spring upper plate Under the limit action of 215, after the disk spring 214 is compressed by force, the pressure is transmitted to the IEGT device through the ball stud 212, the ball socket pressure plate 213, and the insulating pad, so that the entire crimping unit can be crimped. According to the pressure value of the device The requirement is converted into the torque value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com