High-precision fault-tolerant self-driving seat system

A self-driven seat ring, high-precision technology, applied in the field of servo control, can solve problems such as constraints, elastic deformation and wear of transmission gap gears, and reduction of seat ring transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical invention will be further described below using the accompanying drawings and embodiments. The accompanying drawings described here are used to provide a further understanding of the technical invention, constitute a part of the application, and do not constitute a limitation to the technical invention.

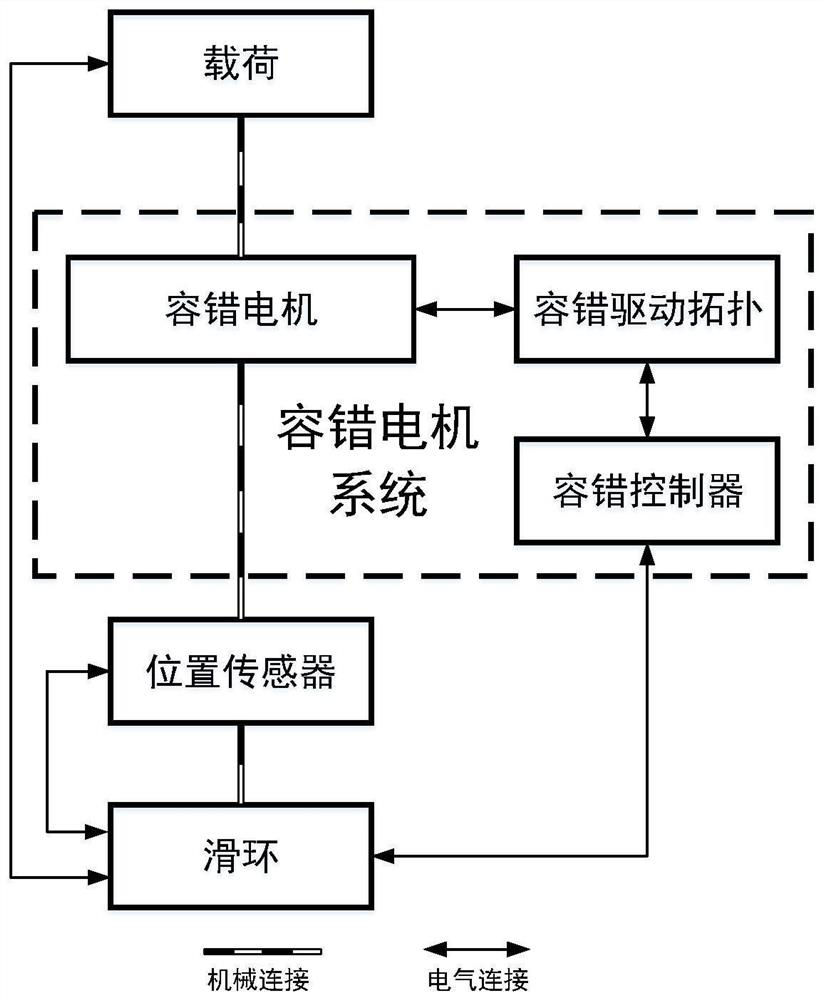

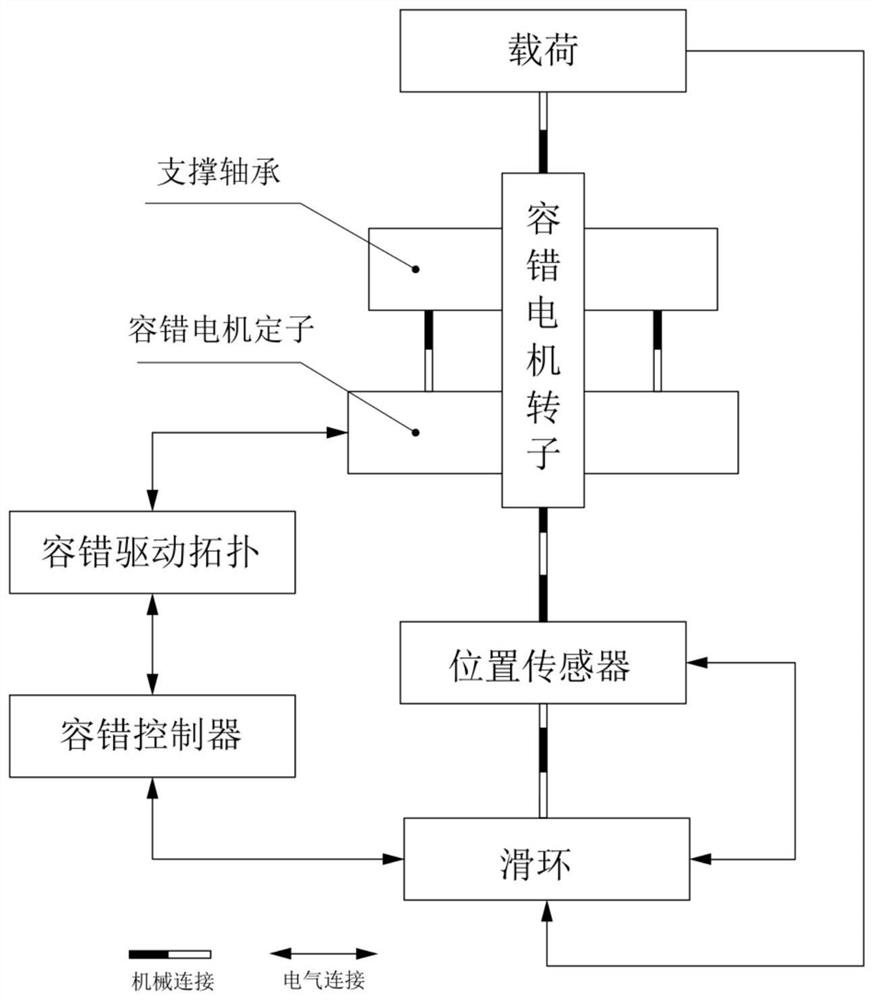

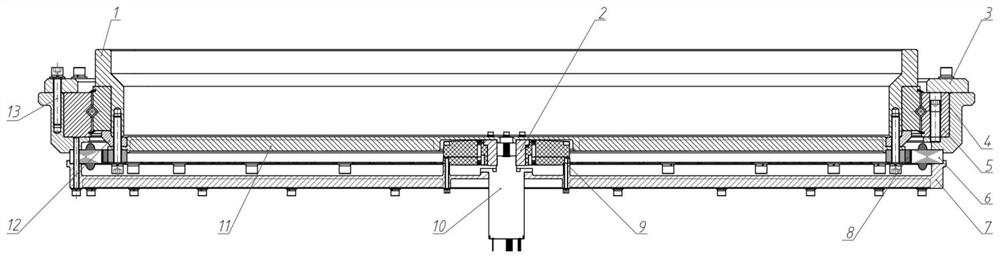

[0019] exist image 3 Among them, the high-precision fault-tolerant self-driving seat system of the present invention relates to the technical field of servo control, and is characterized in that it contains: 1. Seat flange; 2. Angle encoder coupling; 3. Bearing retaining ring I; 4. Large-diameter crossed roller bearing connector; 5. Large-diameter crossed roller bearing; 6. Fault-tolerant motor stator; 7. Slip ring mounting piece; 8. Fault-tolerant motor rotor; 9. Angle encoder; 10. Slip ring; 11. Angle encoder mounting parts; 12. Bearing retaining ring II; 13. Fasteners.

[0020] The seat ring flange 1 and the inner ring of the large-diameter crossed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com