Winch apparatus having automatic tension function

A hoist and functional technology, applied in hoisting device, clockwork mechanism, ship cleaning device, etc., can solve the problems of high price, difficulty, long delivery time, etc., and achieve easy light weight and easy space saving. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

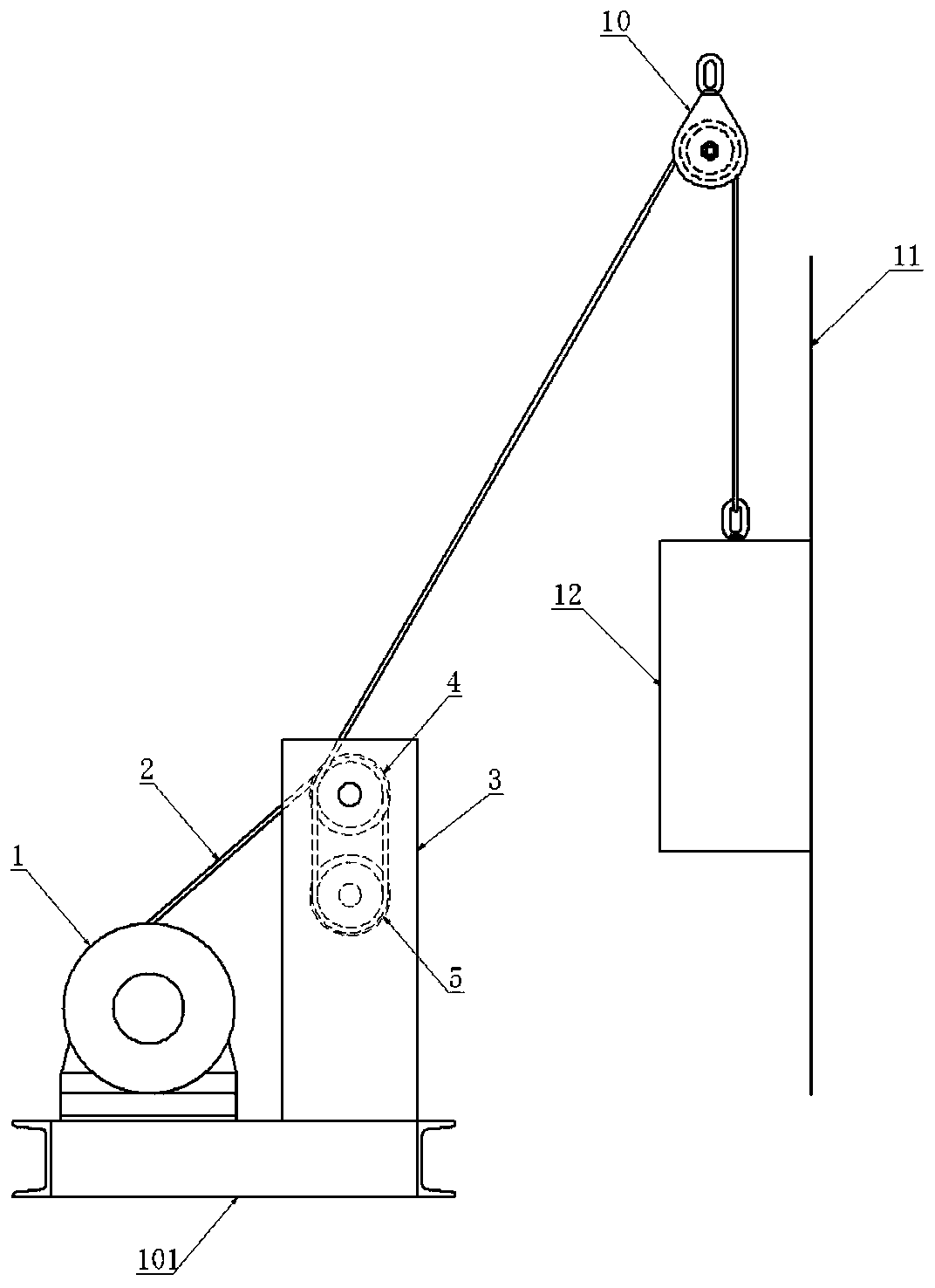

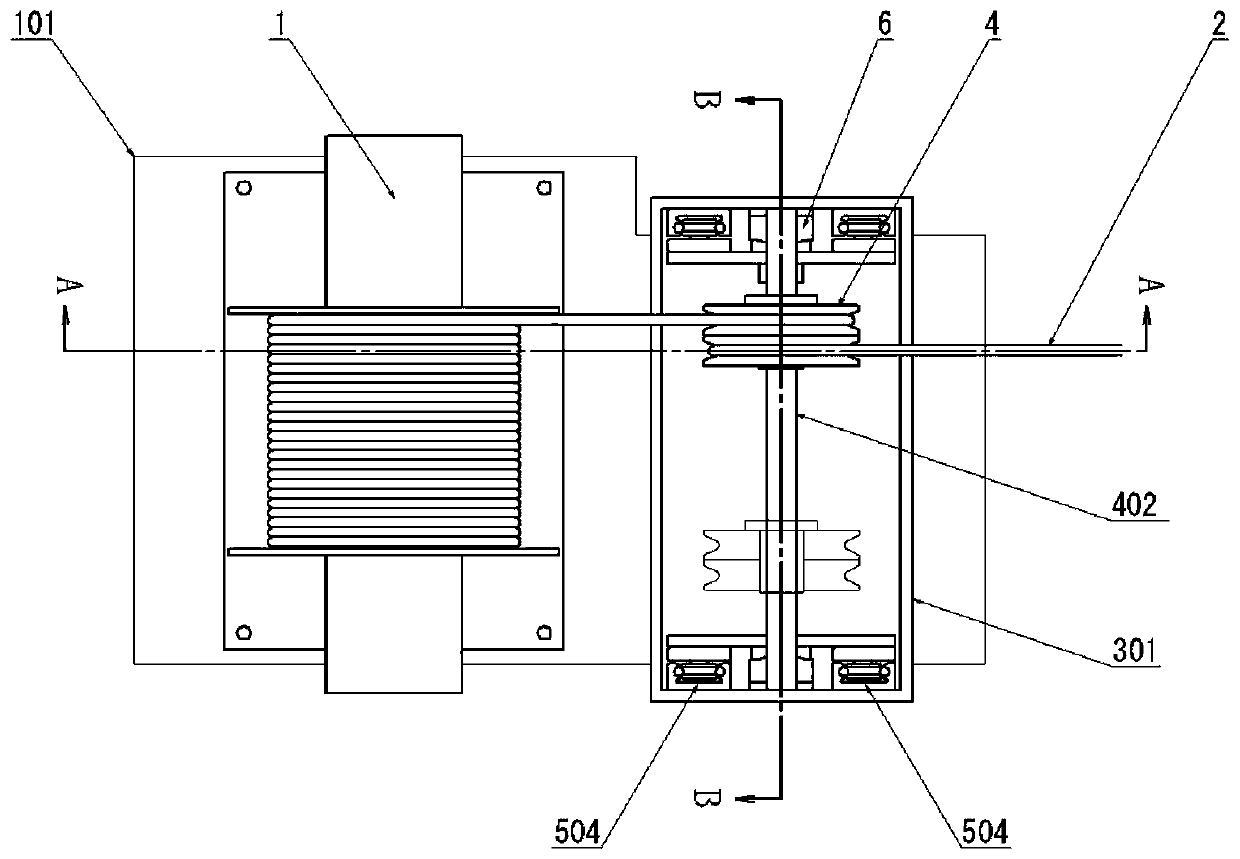

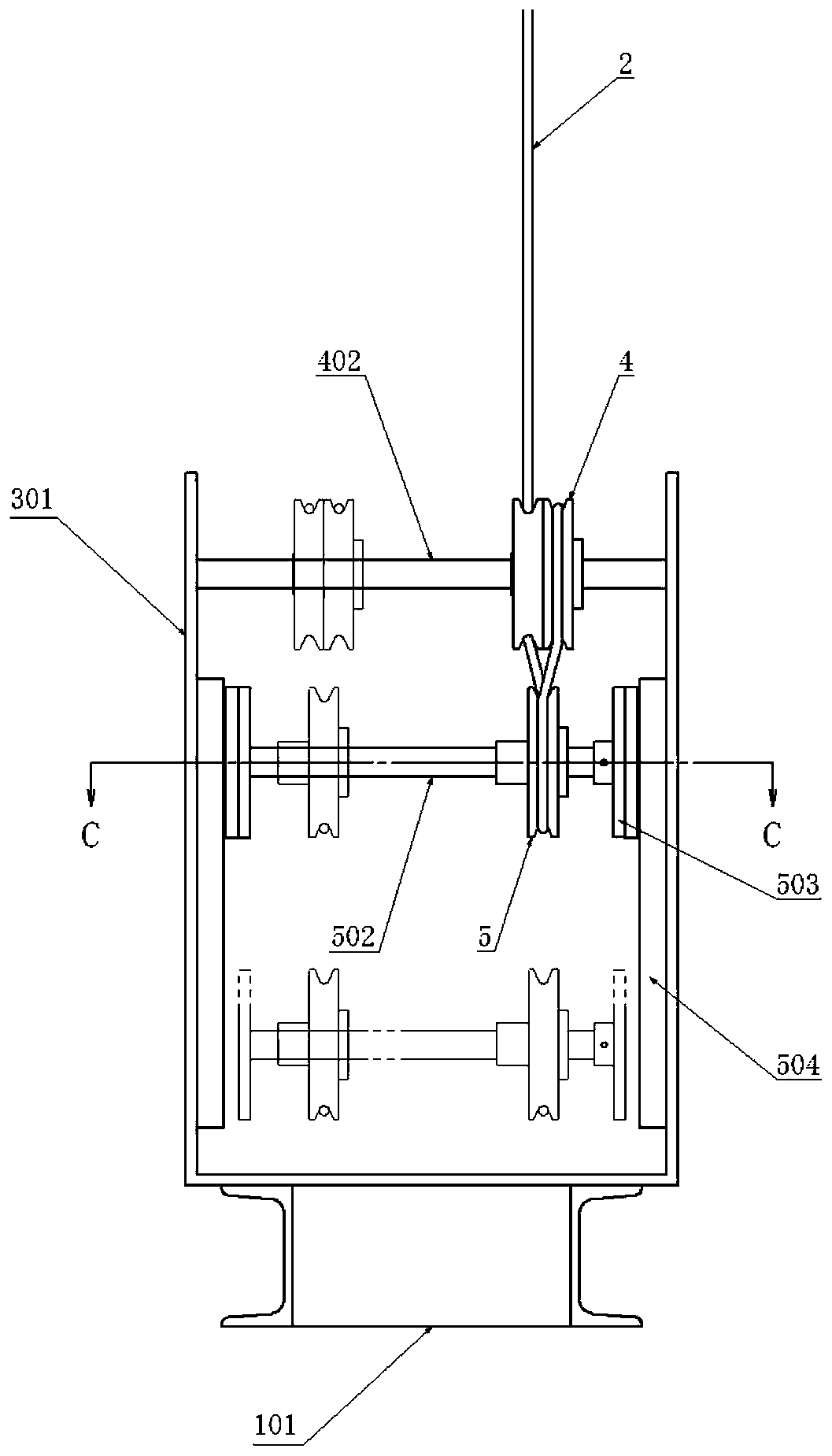

[0095] Hereinafter, a first preferred embodiment of the device according to the present invention will be described with reference to the drawings.

[0096] refer to Figure 1 to Figure 7 For illustration, the illustrated device includes:

[0097] The main body 1 of the hoist with the functions of pulling the cable, retracting the cable, and stopping the cable;

[0098] A steel cable 2 wound on the rotating drum of the winch main body 1;

[0099] Two pulleys 4, 5 suspended in the middle of the steel cable 2, so that when the tension of the steel cable 2 increases, the distance between the pulleys becomes smaller due to the increase of the tension;

[0100] a pulley holding mechanism 3 that holds the pulley and can change the distance between the pulleys,

[0101] The pulley holding mechanism 3 has:

[0102] The upper pulley 4 above is held by the upper pulley shaft 402 via the upper pulley sliding bearing 401,

[0103] The upper pulley 4 can freely rotate according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com