Manned ferry moving system for coal face

A technology of coal mining face and mobile system, which is applied in mining equipment, earth-moving drilling, mining equipment, etc., can solve the problem of short working height and space of working face, low mining efficiency of working face, head, waist and knee limb injuries, etc. problem, to achieve the effect of convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

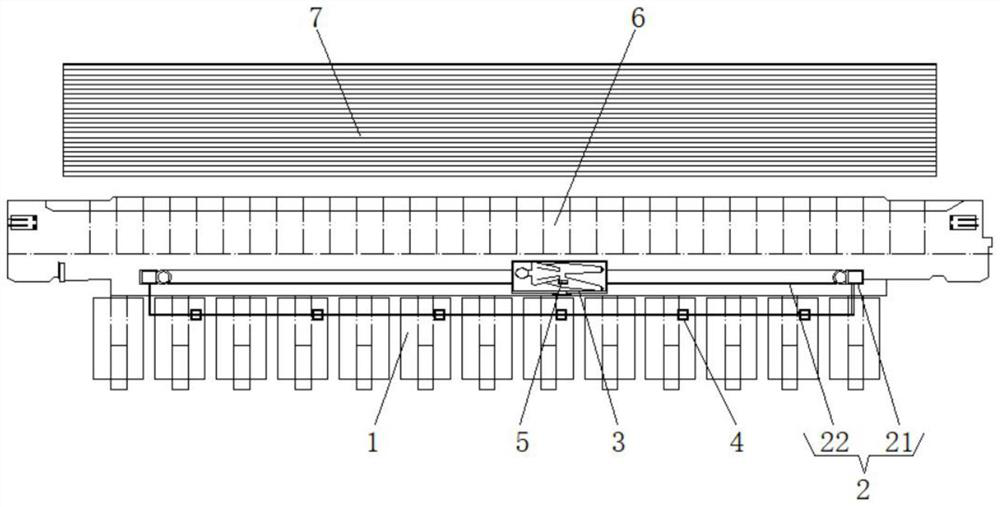

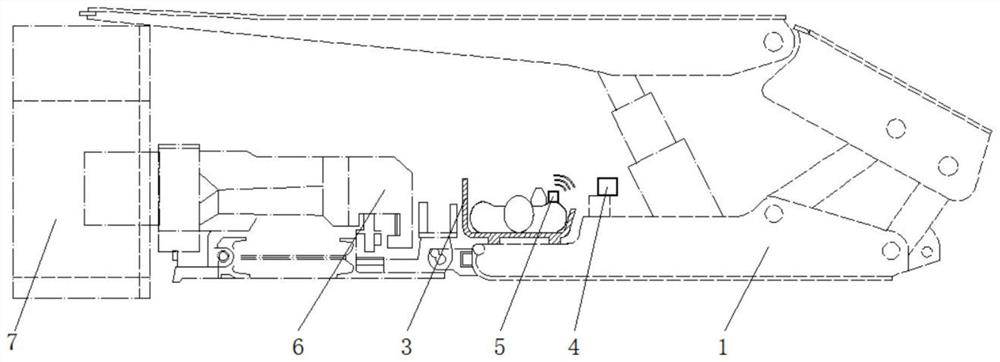

[0022] see Figure 1-Figure 2 , a manned ferry mobile system for a coal mining face, including a hydraulic support 1 and a coal body 7 to be mined, the back side of the hydraulic support 1 is provided with a manned mobile cabin 3, and the inner cavity of the manned mobile cabin 3 A wireless remote control signal generator 5 is provided, and an infinite rope traction mechanism 2 is installed on the rear side of the hydraulic support 1 and between the left and right sides of the manned mobile cabin 3. The infinite rope traction mechanism 2 includes a tractor 21, and the hydraulic support 1- The top of the side and the front side of the manned mobile cabin 3 is fixedly installed with a wireless signal receiving transmitter 4, the scraper conveyor 6 is arranged on the rear side of the hydraulic support 1, and the coal body 7 to be mined is located on the side of the scraper conveyor 6. On the rear side, there is a manned mobile cabin 3 that can slide between the working face hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com