Flower-like MxWO3/SiO2 loaded composite aerogel particle and preparation method thereof

A composite airgel and composite gel technology, which is applied in the field of preparation of flower-shaped MxWO3/SiO2 composite airgel particles, can solve problems that have not been reported, and achieve high pore volume and adsorption capacity, good adsorption/light The effect of catalytic degradation of pollutants and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

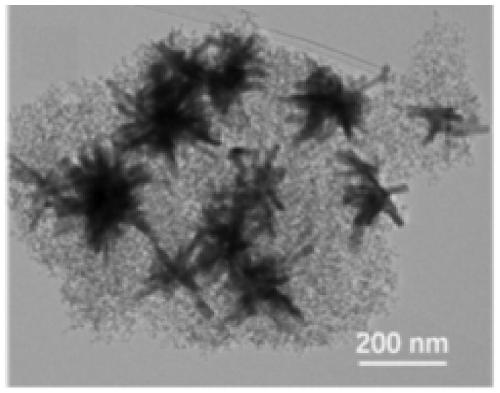

[0033] A loaded flower-like M x WO 3 / SiO 2 The preparation method of composite airgel particle comprises the following process steps:

[0034] ①Dissolve tungstate in water to obtain a tungstate solution with a concentration of 0.01-5mol / L;

[0035] ②Dissolve silicate into water to obtain a silicate solution with a concentration of 0.01-5mol / L;

[0036] ③Convert the prepared tungstate solution and silicate solution into tungstic acid solution and silicic acid solution respectively by cation exchange method;

[0037] ④Measure a certain volume of silicic acid solution and tungstic acid solution, mix under stirring conditions, and add a certain amount of M salt and inducer, stir and mix evenly, and prepare a mixed sol;

[0038] ⑤Aging the mixed sol at a temperature of 20-90°C until it turns into a gel;

[0039] ⑥ Place the composite gel block in absolute ethanol or ethanol aqueous solution, and age at 20-60°C for 1-24 hours;

[0040] ⑦ Select an appropriate solvent as the r...

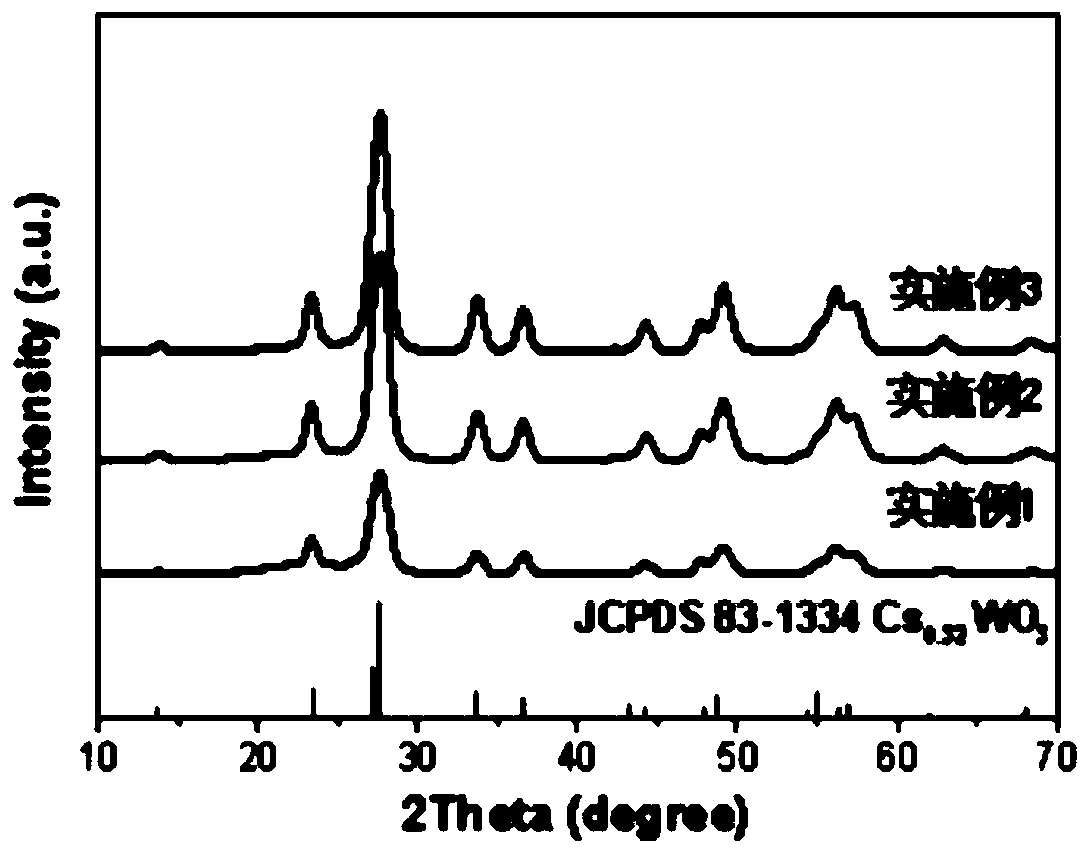

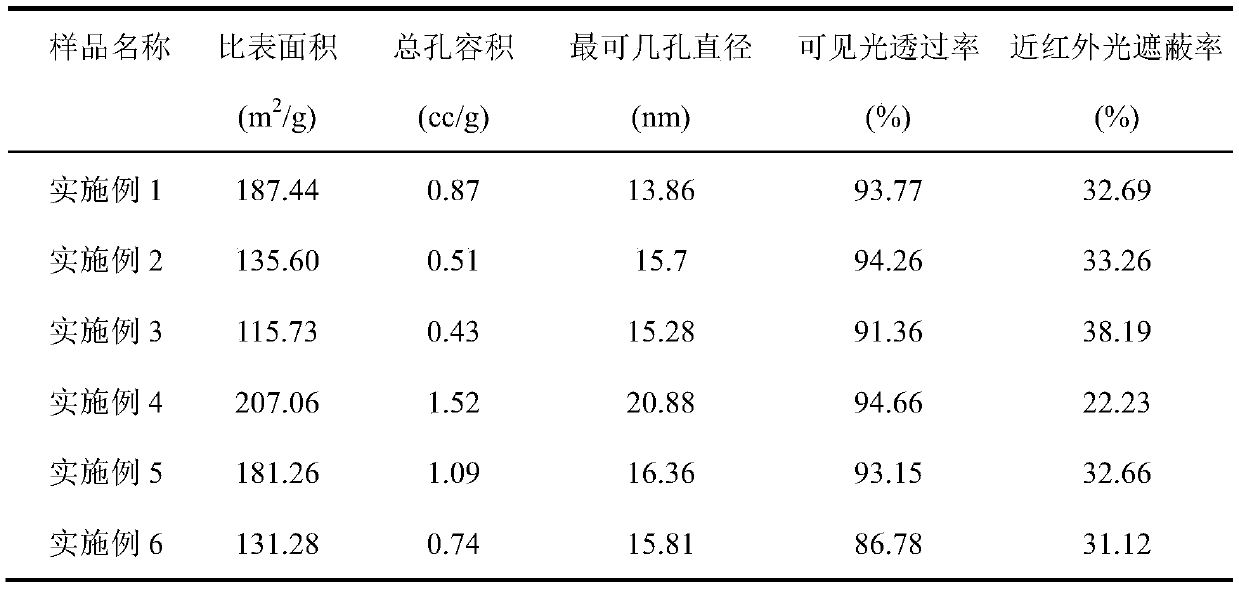

Embodiment 1

[0057] Example 1 Preparation of loaded flower-like Cs with Si / W molar ratio = 5:1 0.5 WO 3 SiO 2 composite airgel

[0058] ① Preparation of silicic acid and tungstic acid solutions by ion exchange method

[0059] The preparation of silicic acid: put the industrial water glass with a modulus of 3.0 into V 水玻璃 :V 水 =1:4 diluted with deionized water, and then ion-exchanged through a styrene-based cation-exchange resin to obtain silicic acid with a pH of 2 to 3;

[0060] Preparation of tungstic acid: first weigh 19.791g sodium tungstate dihydrate and dissolve in 80mL deionized water to prepare Na 2 WO 4 solution, and then undergo ion exchange through a styrene-based cation exchange resin to obtain a tungstic acid solution with a concentration of 0.75mol / L and a pH of 1.5-3.

[0061] ②Preparation of mixed sol and gel

[0062] Under stirring conditions, weigh 30mL of silicic acid solution, 9.36mL of tungstic acid solution, 0.6351g of cesium sulfate, and 8.3189g of citric aci...

Embodiment 2

[0071] Example 2 Preparation of loaded flower-like Cs with Si / W molar ratio = 3:1 0.5 WO 3 SiO 2 composite airgel

[0072] ① Preparation of silicic acid and tungstic acid solutions by ion exchange method is the same as step ① in Example 1.

[0073] ②Preparation of mixed sol and gel

[0074] Under stirring conditions, weigh 25mL of silicic acid solution, 13mL of tungstic acid solution, 0.7942g of cesium carbonate, and 3.44g of oxalic acid and mix in sequence to prepare a mixed sol; place the mixed sol in a 60°C water bath to make it gel.

[0075] ③ Composite gel aging and solvothermal reaction are the same as step ③ in Example 1.

[0076] Place the composite gel in 50% ethanol aqueous solution, and age at 25°C for 24 hours; then measure 50mL of ethanol to prepare a gel block reaction solution, place the composite gel block in the reaction liquid, and react at 190°C After 72h, the solvothermal reaction was completed.

[0077] ④The modification and atmospheric pressure dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap