Correcting and docking method for large-diameter steel pipes

A large-diameter, steel pipe technology, applied in the field of large-diameter steel pipe rectification and docking, steel structure construction, can solve the problems of many follow-up work, time-consuming and labor-intensive, and difficult to guarantee the forming quality, so as to reduce the number of workers, avoid duplication of work, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

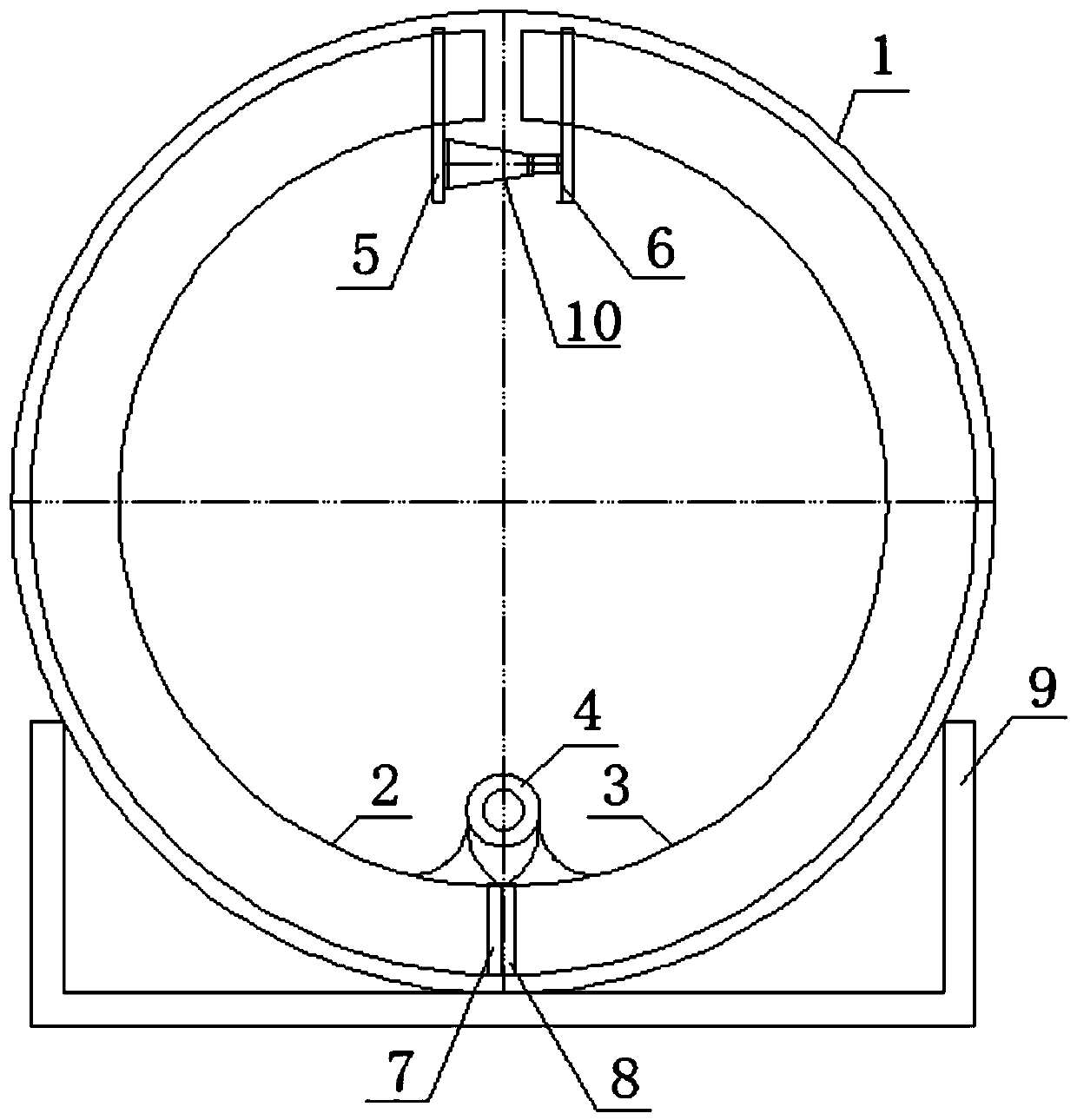

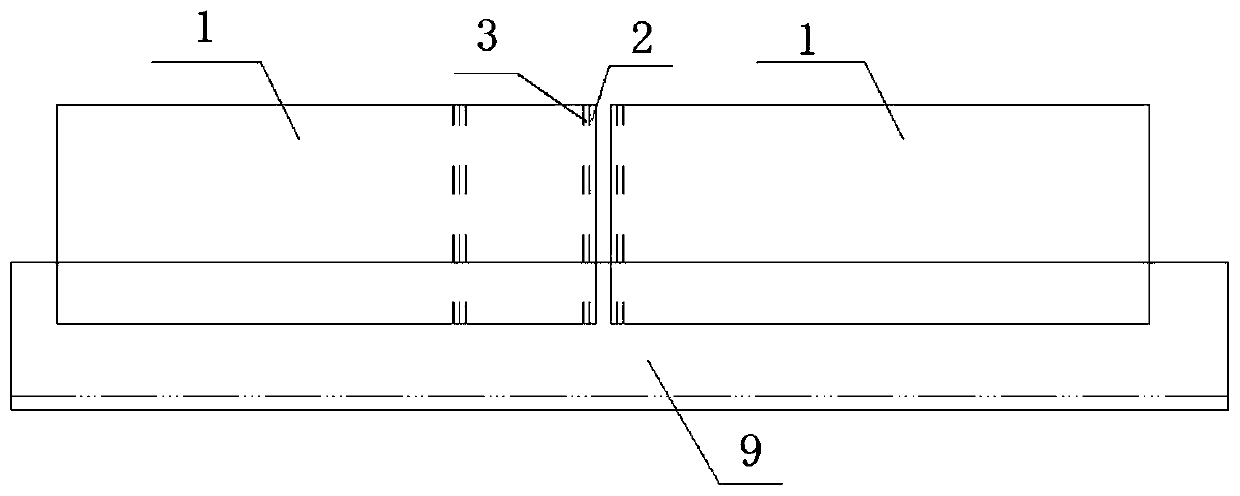

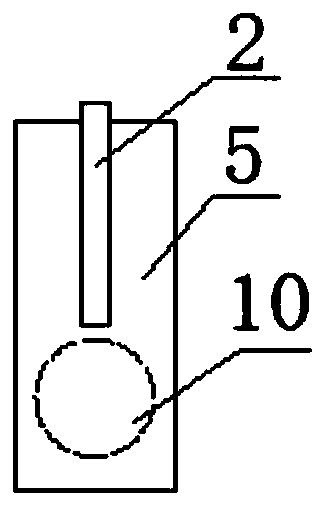

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0033] The present invention provides a technical solution: a method for correcting butt joint of large-diameter steel pipes, comprising the following steps:

[0034] S1. Measure the roundness of the outer surface of the steel pipe 1, count the measurement data, and mark the position different from the roundness of the standard steel pipe as the correction point;

[0035] S2. At the above-mentioned correction point, the steel pipe is supported by the correction part so that the roundness of the above-mentioned steel pipe 1 is the same as that of the standard steel pipe;

[0036] S3. Align and connect the corrected steel pipe with other corrected steel pipes.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com