Air conditioner external unit shell manufacturing and machining technology

A technology of air conditioner external unit and processing technology, applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc. The quality of the machine shell is not up to standard, etc., to achieve the effect of reducing the cycle, reducing the sliding, and reducing the friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

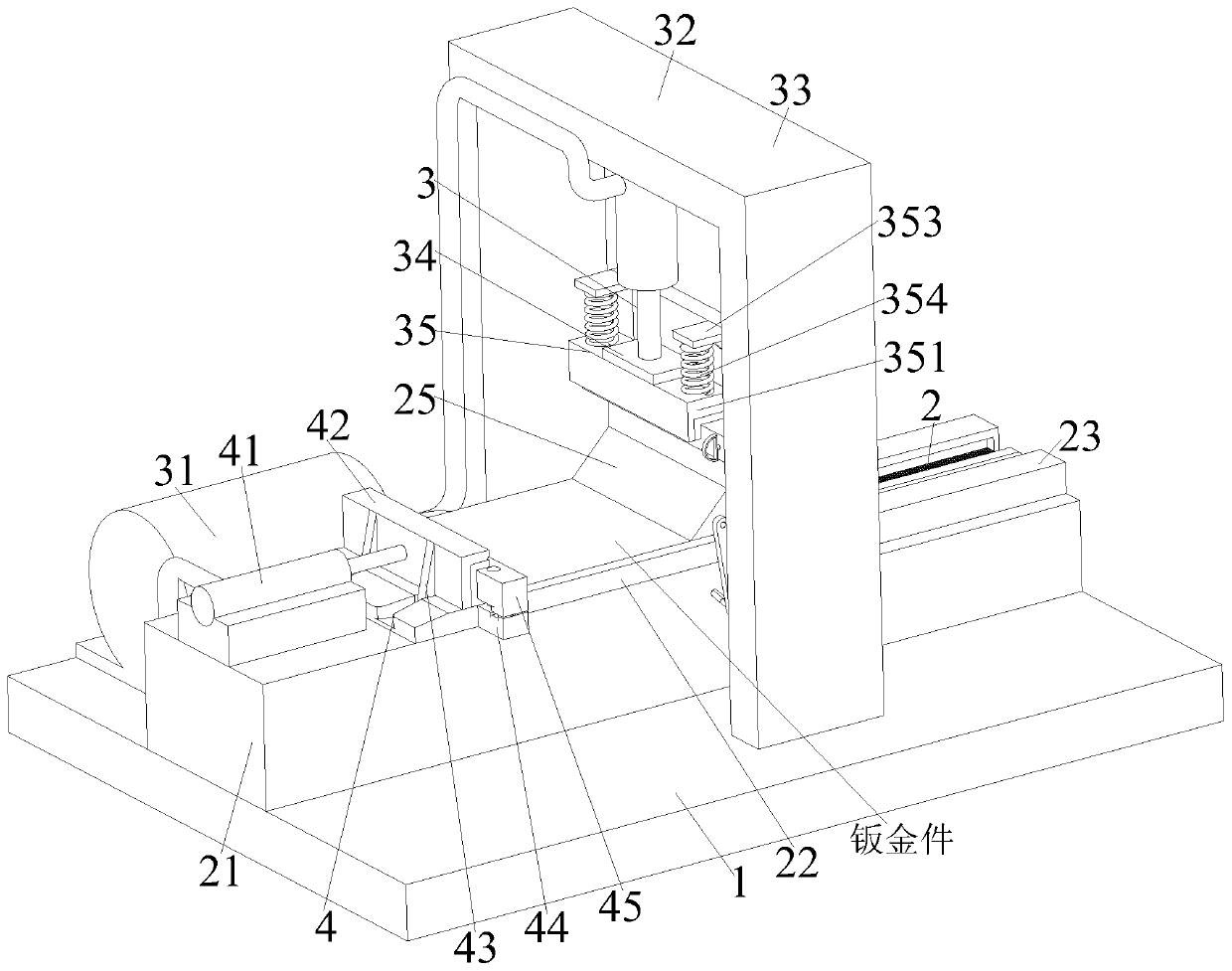

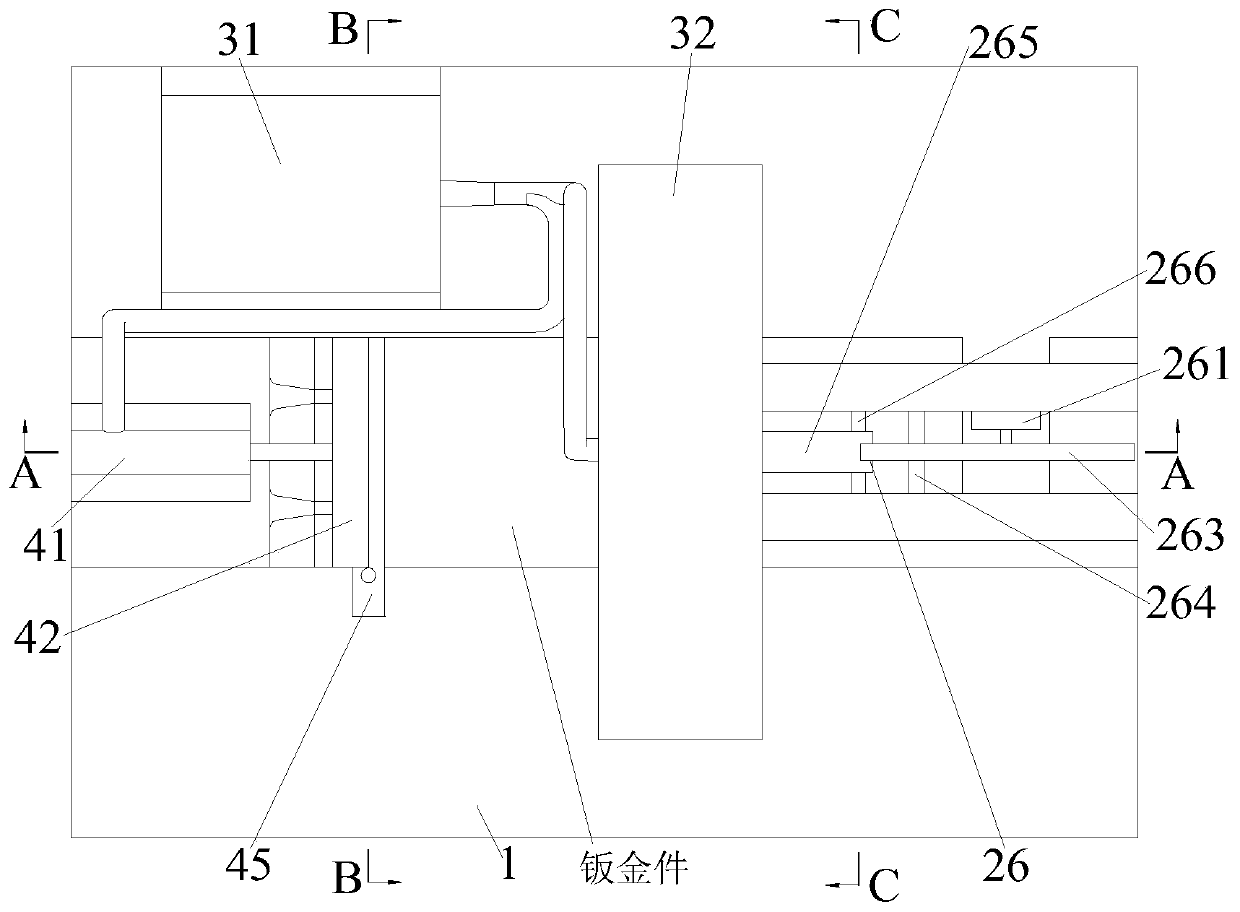

[0040] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 11 , to further elaborate the present invention.

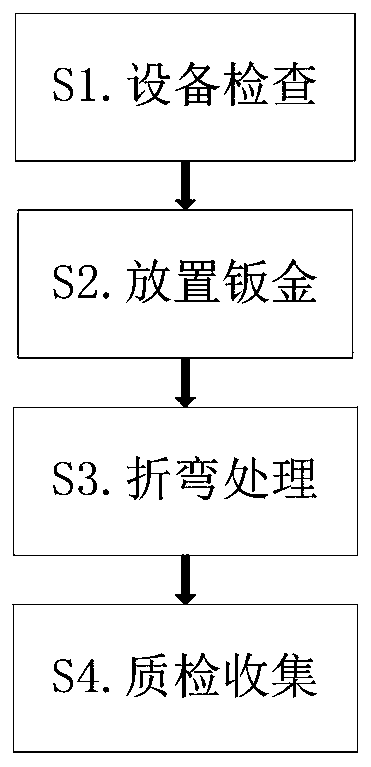

[0041] A manufacturing and processing process for an air conditioner external unit shell, the specific manufacturing and processing process is as follows:

[0042] S1. Equipment inspection: check the manufacturing and processing equipment of the air conditioner outer unit before using the manufacturing equipment for the outer unit of the air conditioner to process the outer unit of the air conditioner;

[0043] S2. Place the sheet metal: place the sheet metal to be bent on the workbench 1 manually;

[0044] S3. Bending processing: After the sheet metal is placed, the middle part of the sheet metal is bent by the middle bending device 2. After the middle part of the sheet metal is bent, the upper end of the sheet metal is bent by the upper end bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com