Fault Diagnosis and Control Method of Automobile Vacuum Pump

A fault diagnosis and control method technology, applied in the direction of brakes, vehicle components, brake safety systems, etc., can solve the problem of not being able to ensure the normal operation of the vacuum pump safely, efficiently and quickly, not being able to provide fault reasons to maintenance personnel, and the degree of vacuum pump fault diagnosis is simple, etc. problems, to achieve the effect of improving safety performance and braking performance, in-depth and comprehensive fault diagnosis, and more stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

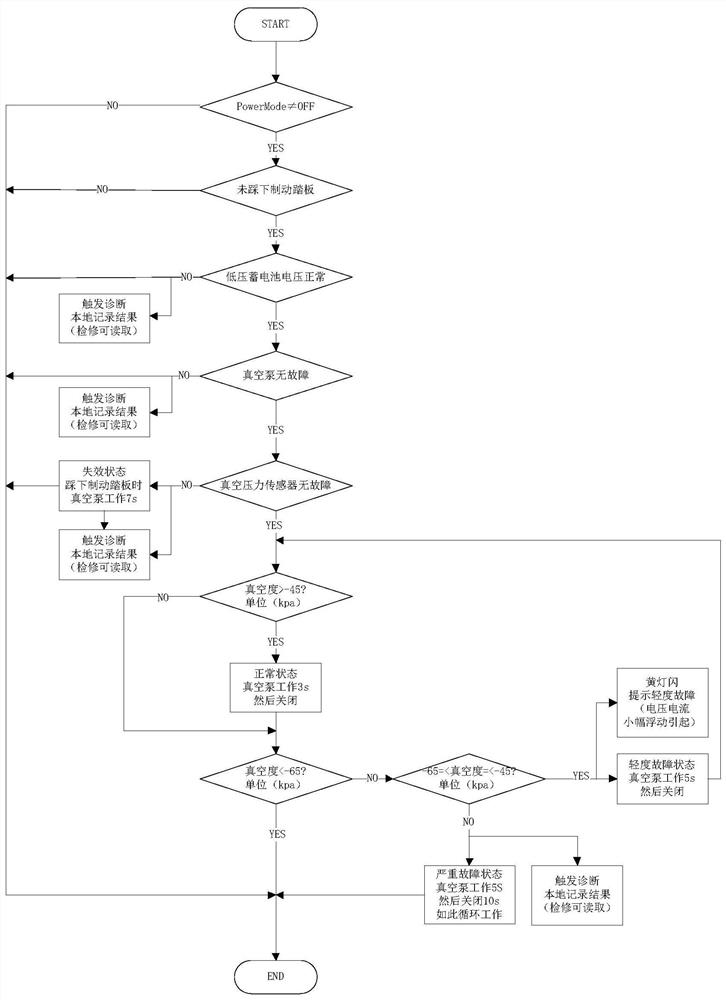

[0026] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0027] The purpose of the present invention is to formulate a more comprehensive vacuum pump control and diagnosis strategy, to efficiently and quickly control the normal operation of the vacuum pump, to better assist automobile braking and ensure safety.

[0028] Vacuum booster system, mainly including: automotive low-voltage battery, vacuum pressure sensor, vacuum pump, booster system controller, brake pedal, automotive power switch

[0029] The scheme is as follows:

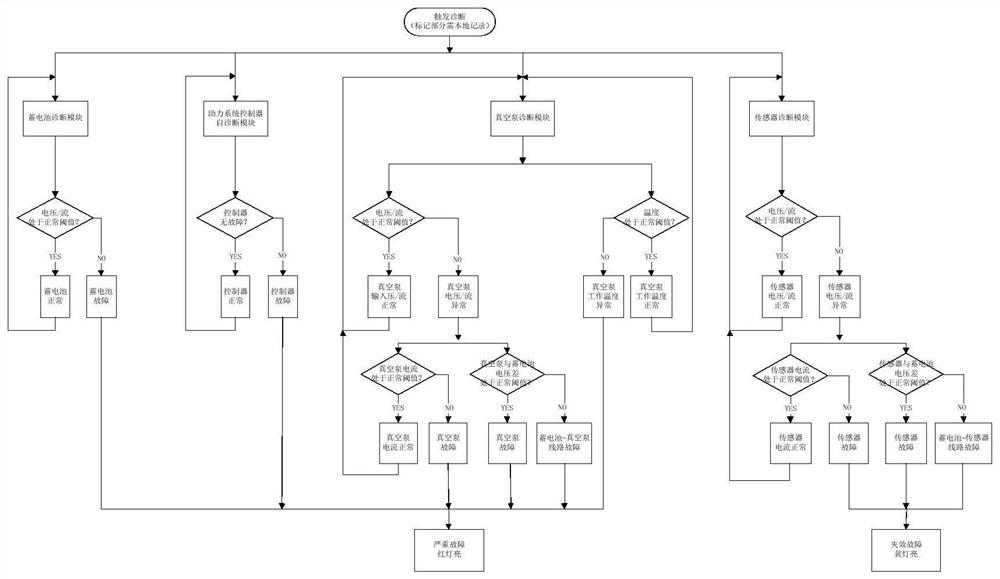

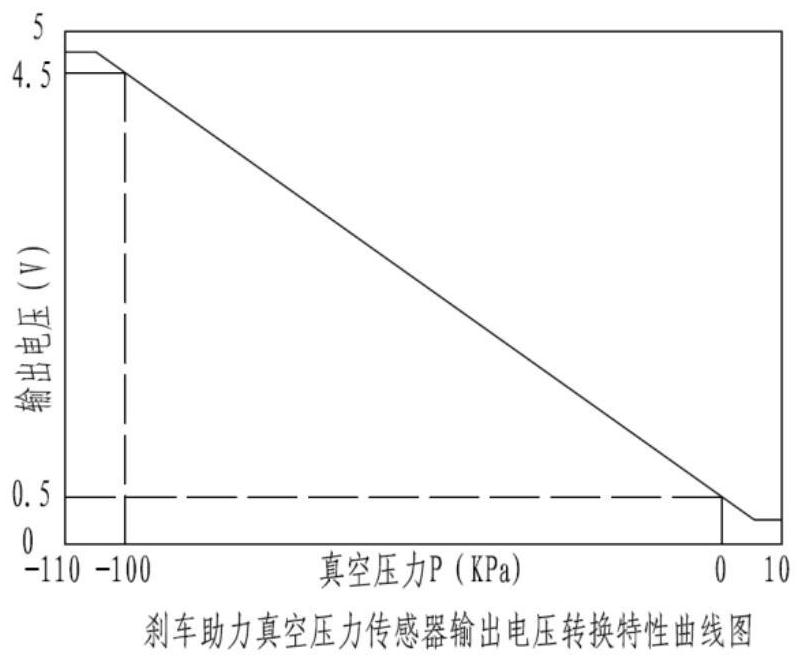

[0030] The VCU controls the switch of the vacuum pump according to the collected vacuum pressure value, maintains the vacuum within a certain range, and ensures the normal operation of the brake booster system. In addition, fault diagnosis and treatment are performed on vacuum pressure sensors and vacuum pumps to reduce po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com