High-integration wheel-leg composite mechanism and carrying platform

A technology that integrates wheels and wheel legs, applied in motor vehicles, transportation and packaging, etc., can solve the problems of not being applied on a large scale, complex structure and control, poor motion stability, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

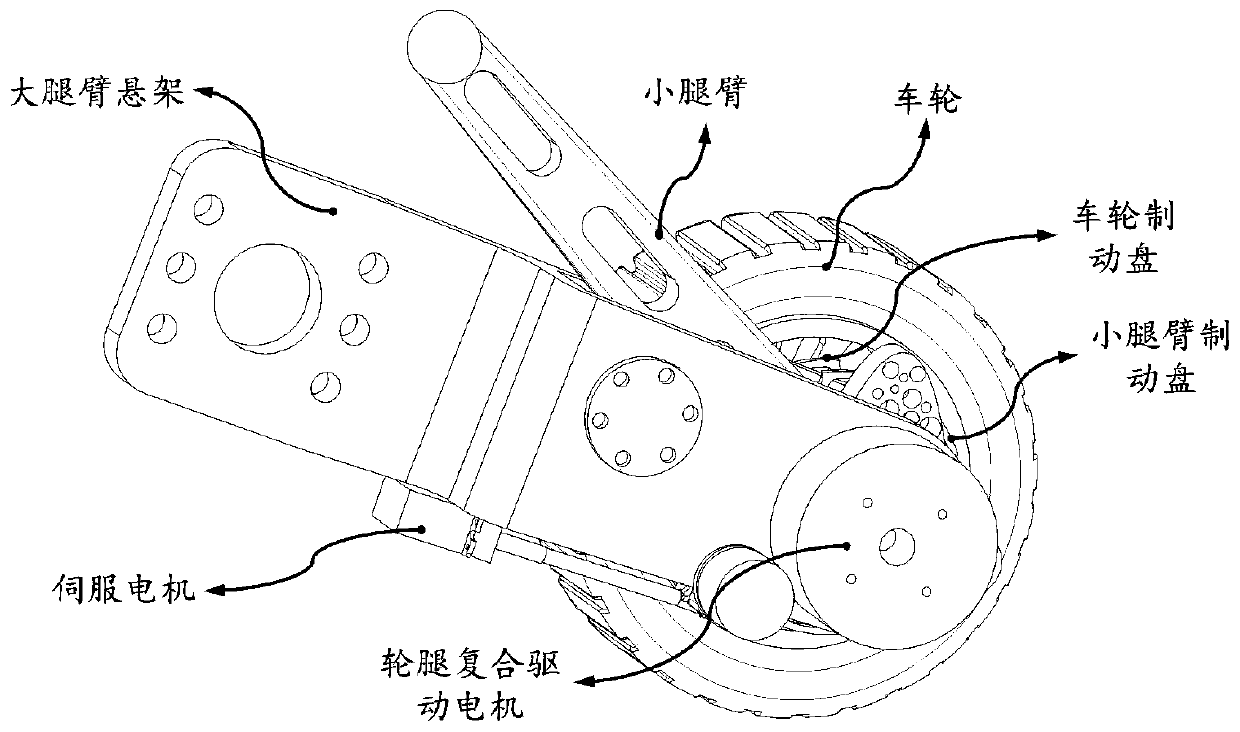

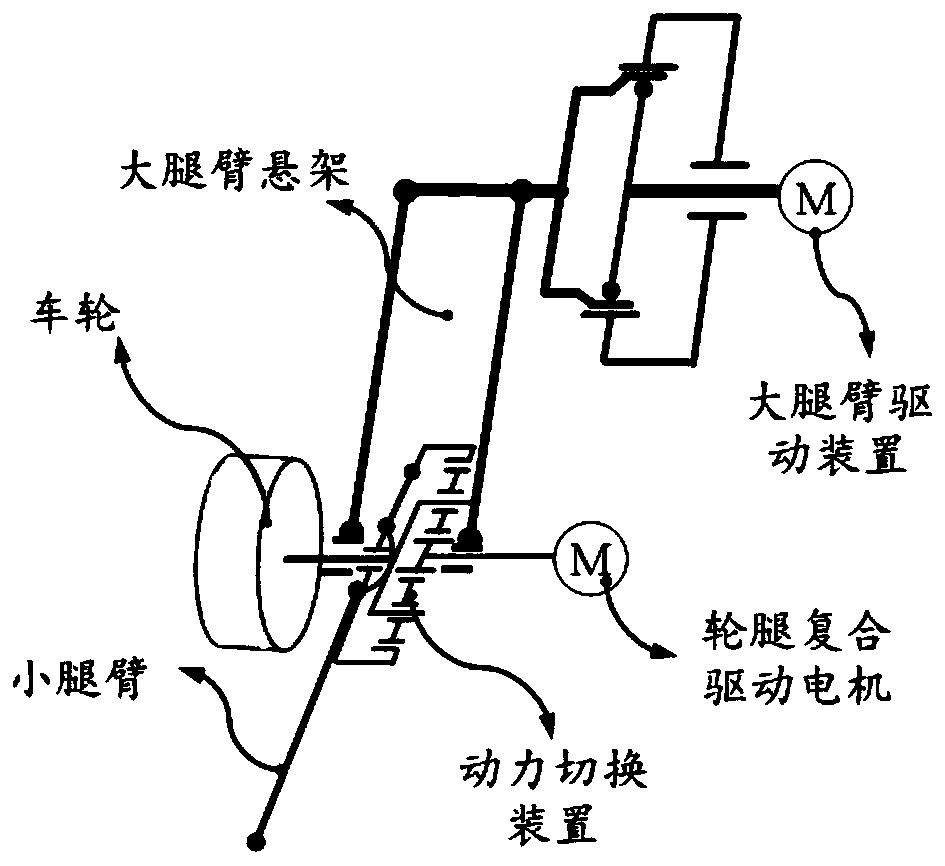

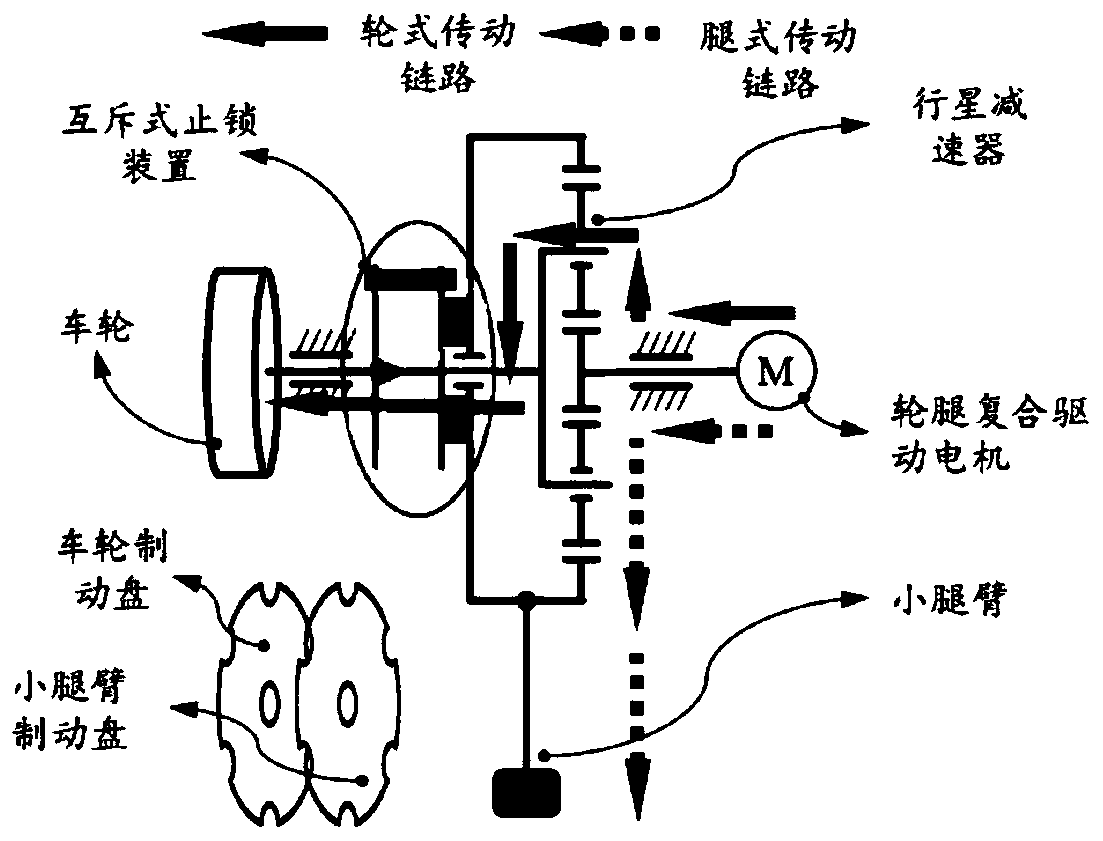

[0027] Figure 1 to Figure 9 It shows a specific embodiment of a highly integrated wheel-leg composite mechanism of the present invention, such as figure 1 , figure 2 , image 3 As shown, it includes the wheel, the lower leg arm, the wheel-leg compound drive motor, the power switching device for transmitting the power of the wheel-leg compound drive motor to the wheel or the leg arm, and the mutually exclusive locks for locking the wheel or the leg arm respectively. Lock device, the output shaft of the wheel-leg compound drive motor is connected to the input shaft of the power switching device, the first output shaft of the power switching device is connected to the wheel shaft, and the top of the lower leg arm is sleeved on the second output shaft of the power switching device , the wheel shaft, the first output shaft and the second output shaft of the power switching device are coaxially arranged, and the mutually exclusive locking device is located between the wheel and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com