Mapping equipment, installing method and key structure for mapping equipment installation

A technology for equipment installation and equipment, which is applied to mechanical equipment, valve devices, connecting components, etc., and can solve the problems of difficult installation, difficult alignment of installation holes and installation points, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

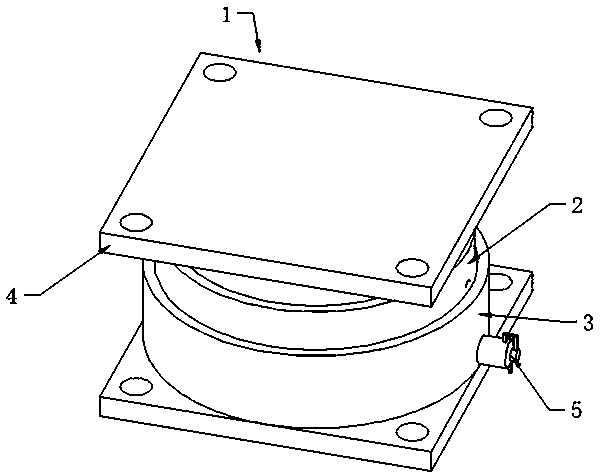

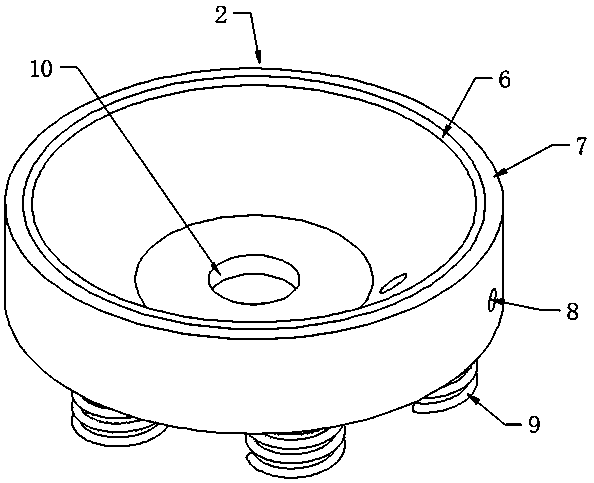

[0025] see Figure 1-3 , an embodiment provided by the present invention: a surveying and mapping equipment, including an installation docking structure 1; the installation docking structure 1 includes an exhaust main body 2, a fixed seat 3, a docking seat 4 and a suction cup main body 5, and the lower end of the docking seat 4 is adsorbed and fixed On the upper end of the exhaust main body 2, the lower end of the exhaust main body 2 is slidably installed on the upper end of the fixed seat 3, the exhaust main body 2 is adsorbed and fixed by the fixed seat 3, and the suction cup main body 5 is fixedly installed by the fixed seat 3; the exhaust main body 2 includes the first A sealing ring 6, a cover plate 7, a spring 9 and an air vent 10, the first sealing ring 6 is fixedly installed through the cover plate 7, the spring 9 is uniformly fixedly connected to the lower end of the cover plate 7, and the air vent 10 is hollowed out at the bottom of the cover plate 7 The lower end; t...

Embodiment 2

[0031] see figure 2 , an embodiment provided by the present invention: an exhaust main body for surveying and mapping equipment installation, including a first sealing ring 6, a sleeve 7, a spring 9 and a vent 10, and the first sealing ring 6 is fixed by the sleeve 7 Installed, the spring 9 is uniformly and fixedly connected to the lower end of the sleeve 7, and the vent 10 is hollowed out at the lower end of the sleeve 7.

Embodiment 3

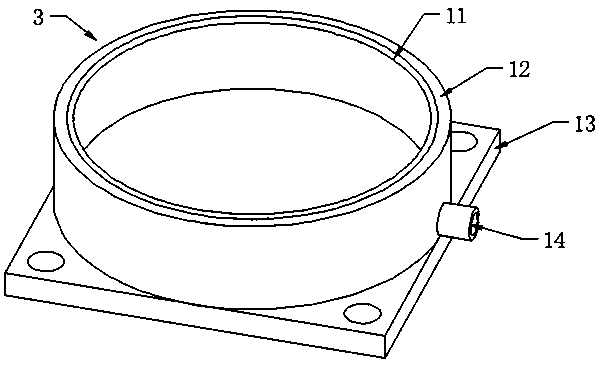

[0033] see image 3 , an embodiment provided by the present invention: a fixing seat for surveying and mapping equipment, including a second sealing ring 11, a sealing shell 12 and a first fixing plate 13, the second sealing ring 11 is fixed by the sealing shell 12 Installation, the second sealing ring 11 is sealed and installed on the outer wall of the sleeve 7, the sleeve 7 is slidably installed on the inner wall of the sealing shell 12, and the first fixing plate 13 is fixed by the lower end of the sealing shell 12 connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com