Explosion-proof valve and explosion-proof valve isolation net aperture design method and system

A technology of isolation nets and explosion-proof valves, which is applied in computing, image data processing, instruments, etc., can solve problems such as open flames outside the box, hidden safety hazards, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

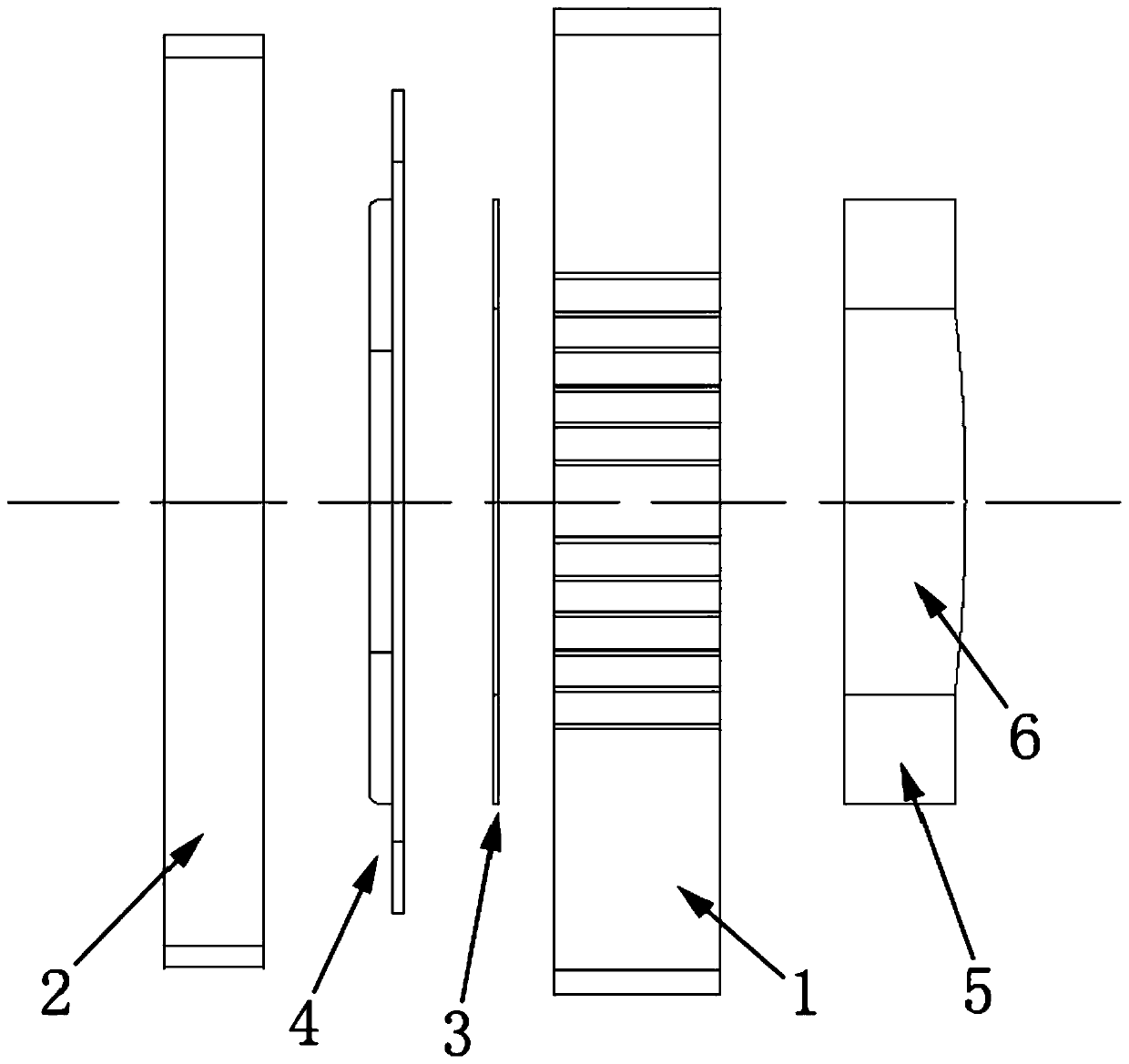

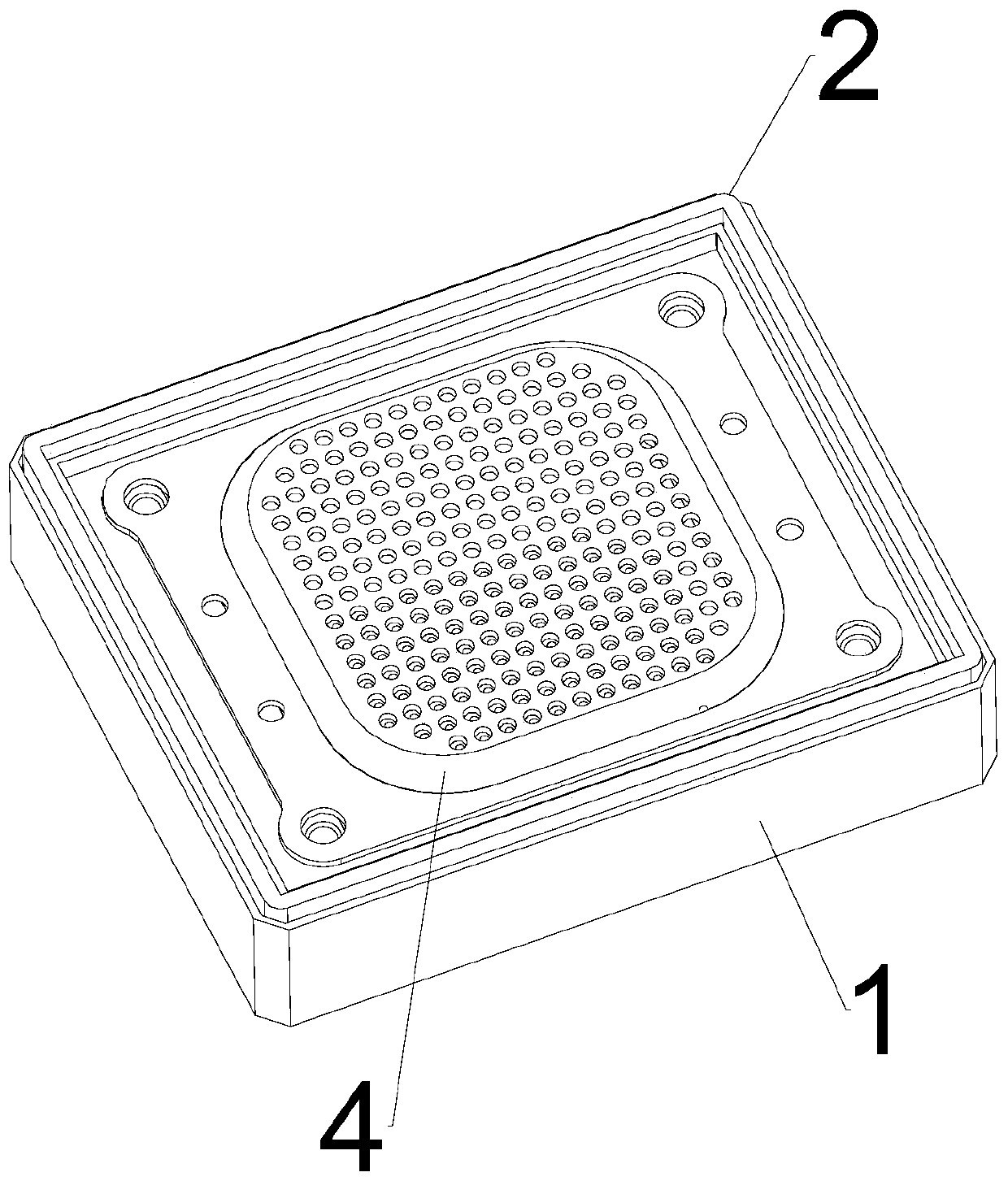

[0040] see figure 1 and figure 2 , providing an explosion-proof valve for a battery box of a multi-element battery, comprising a housing 1, a sealing ring 2, a waterproof and breathable membrane 3, an isolation net 4 and an upper cover 5; the center of the housing 1 is formed with a port 6, The edge of the housing 1 is formed with an annular sealing groove, the sealing ring 2 is placed in the annular sealing groove, the waterproof and breathable membrane 3 and the isolation net 4 are both placed inside the housing 1, the The waterproof breathable membrane 3 covers the port 6, the isolation net 4 covers the waterproof breathable membrane 3, and the isolation net 4 is distributed with mesh holes determined according to the particle size of the solid particles ejected from the thermal runaway of the multi-component battery; The sealing ring 2 is covered on the periphery of the waterproof and gas-permeable membrane 3 and the isolation net 4;

[0041] Specifically, the isolation...

Embodiment 2

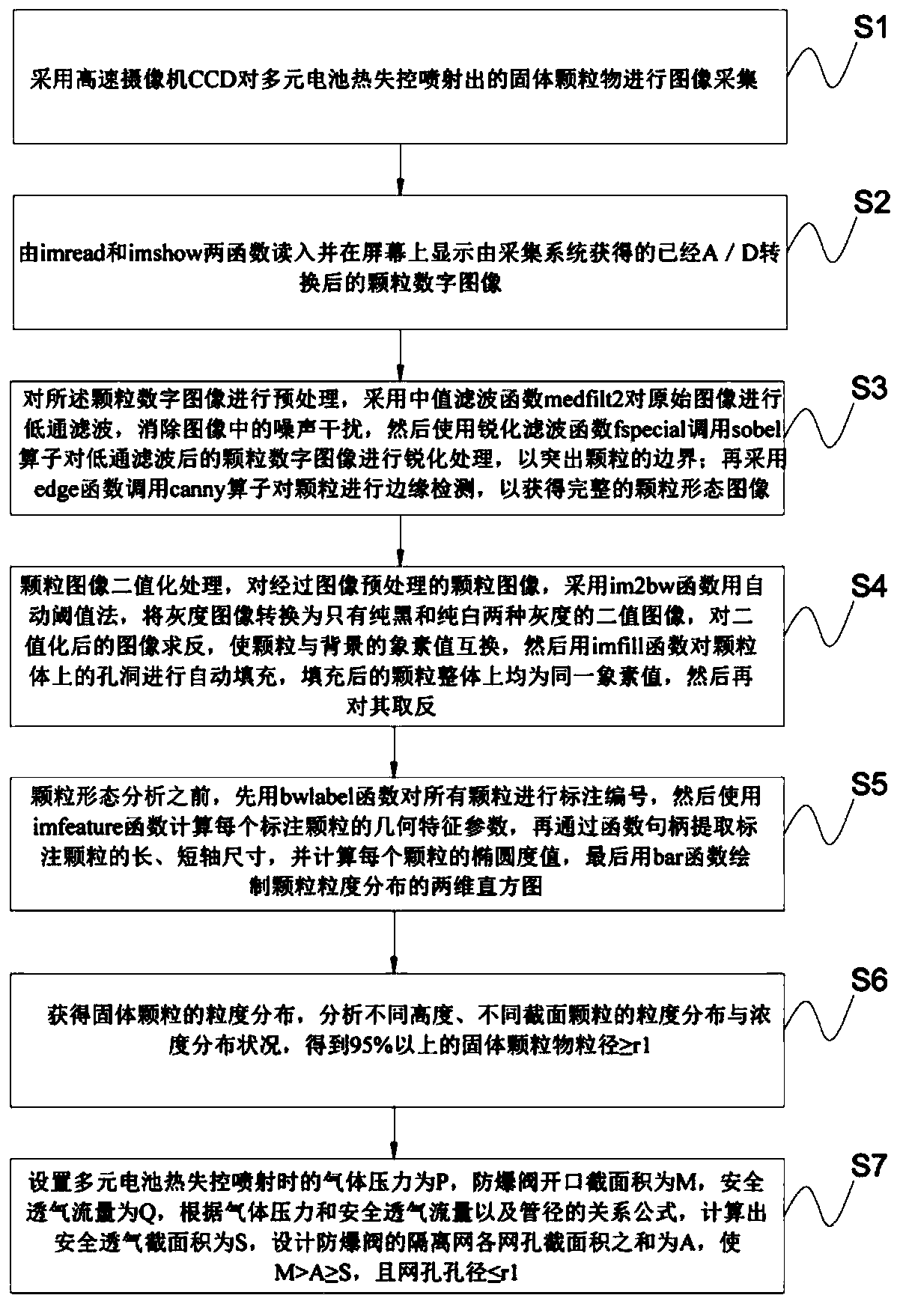

[0045] The present invention also provides a method for designing the aperture of the isolation net of an explosion-proof valve, see image 3 , including the following steps:

[0046] S1: Use a high-speed camera CCD to collect images of the solid particles ejected from the thermal runaway of the multi-element battery;

[0047] S2: The A / D converted particle digital image obtained by the acquisition system is read in by the two functions of imread and imshow and displayed on the screen;

[0048] S3: Preprocess the particle digital image, use the median filter function medfilt2 to perform low-pass filtering on the original image to eliminate noise interference in the image, and then use the sharpening filter function fspecial to call the sobel operator to low-pass filter the original image The particle digital image is sharpened to highlight the boundary of the particle; then the edge function is used to call the canny operator to detect the edge of the particle to obtain a com...

Embodiment 3

[0058] The present invention additionally provides an aperture design system for the isolation net of an explosion-proof valve, see Figure 4 ,include:

[0059] The image acquisition module 7 is used to acquire images of the solid particles ejected from the thermal runaway of the multi-element battery by using a high-speed camera CCD;

[0060] The image display module 8 is used for reading in by the two functions of imread and imshow and displaying the A / D converted particle digital image obtained by the acquisition system on the screen;

[0061] The image preprocessing module 9 is used for preprocessing the digital image of the particles, using the median filter function medfilt2 to perform low-pass filtering on the original image, eliminating noise interference in the image, and then using the sharpening filter function fspecial to call the sobel operator Sharpen the particle digital image after low-pass filtering to highlight the boundary of the particle; then use the edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com