Short-range straight-line bipolar plate for fuel cell

A fuel cell and in-line technology, applied to fuel cells, fuel cell components, circuits, etc., can solve the problems of low effective area ratio of the core power generation part and relying on pipelines for realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention relates to a short-distance in-line bipolar plate for a fuel cell. The bipolar plate is composed of an anode-side unipolar plate and a cathode-side unipolar plate bonded together on the back side. Both the anode-side unipolar plate and the cathode-side unipolar plate include a rectangular substrate, and the material of the substrate can be a conductive plate such as a graphite plate, a composite graphite plate, or a metal plate. In this embodiment, a graphite plate with a thickness of 1.5 mm is used as the substrate, and the outer dimension of the substrate is 193×83.8 mm.

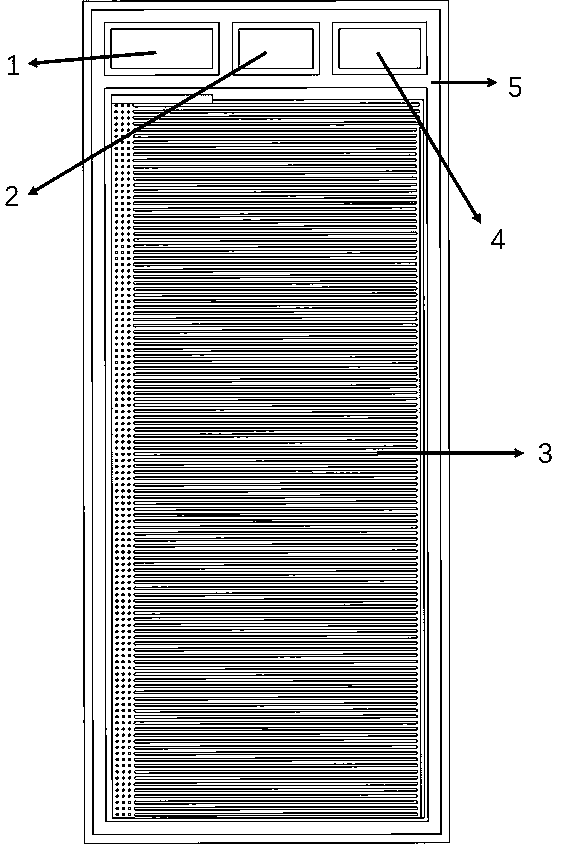

[0028] The front side of the cathode side unipolar plate or the anode side unipolar plate as figure 1 As shown, the center of the substrate is provided with a gas flow field area 3, and the upper part of the gas flow field area 3 is provided with a front air inlet 1, a cooling liquid inlet 2 and an anode / cathode gas inlet 4 (the cathode side single The polar plate corresponds to the a...

Embodiment 2

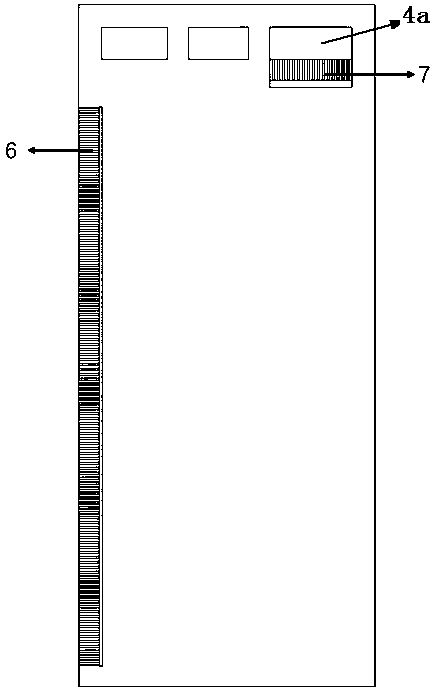

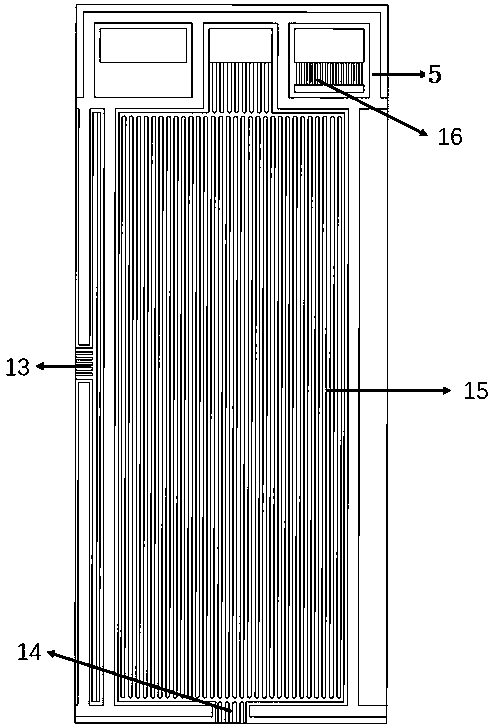

[0032] In this embodiment, the design of the front flow field of the cathode-side unipolar plate and the anode-side unipolar plate is the same as that of Embodiment 1. The difference is the position of the cathode gas outlet 6 on the back of the cathode-side unipolar plate, the anode gas outlet 13 and the coolant outlet 14 on the back of the anode-side unipolar plate, such as Figure 4 As shown, the cathode gas outlet 6 is located at the lower part of the back side edge of the cathode-side unipolar plate, the bottom of the cathode gas outlet 6 is 10.8mm away from the bottom of the substrate, and the size it occupies is 8.4×4.6mm, the width of the outlet flow channel is 0.8mm, and the ridge The width is 0.6mm, and the groove depth is 0.6mm. Such as Figure 5 As shown, the anode gas outlet 13 is located at the lower part of the back side edge of the anode side unipolar plate, the bottom of the anode gas outlet 13 is 10.8mm away from the bottom of the substrate, and the size it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com