Thin film surface uniform shearing force loading device

A technology with a uniform surface and a loading device, which is applied in the direction of measuring devices, using stable shear force to test the strength of materials, instruments, etc., can solve the problems of direct loading of unfavorable forces, complex degradation process, and failure to fully grasp, etc., to achieve improvement Effect of effective area ratio and flow stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

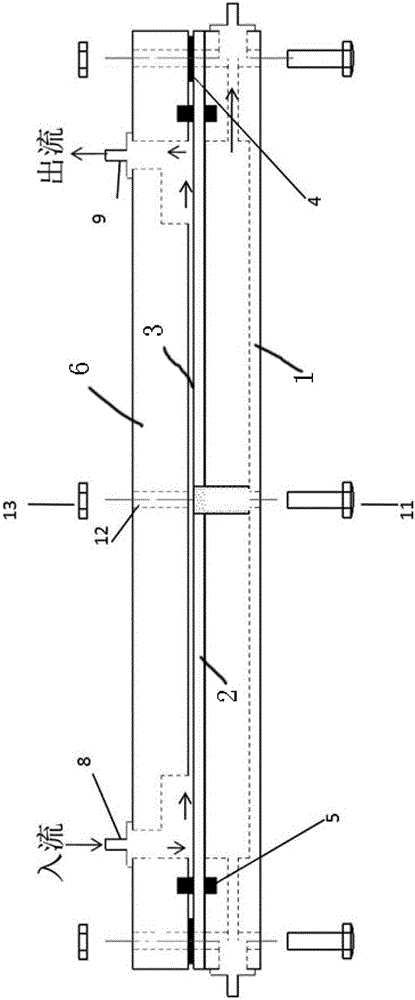

[0014] Such as figure 1 As shown, the film surface uniform shear force loading device according to an embodiment of the present invention includes a bottom plate 1, a glass slide 2, a film 3, a silicone gasket 4, a sealing ring 5, a cover plate 6 and a fluid in the form of a 316L stainless steel joint. By inlet 8 and fluid outlet 9. The fluid flows in from the inlet 8, after being buffered on the inlet buffer platform, after a little gentleness, it enters the L-shaped closing of the inlet. Due to the narrow L-shaped closing at the inlet end, after the fluid becomes more uniform in the cavity width direction of the flow cavity, it enters the effective flat plate area to form a uniform shear stress field with a large area.

[0015] Then the fluid flows out to the outlet buffer platform through the L-shaped closing port at the end, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com