Efficient full-screen flow field bipolar plate for fuel cell and battery stack thereof.

A fuel cell and bipolar plate technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of large area ratio and low effective area ratio of power generation parts, so as to improve production efficiency, enhance design flexibility, and improve Effect of effective area ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

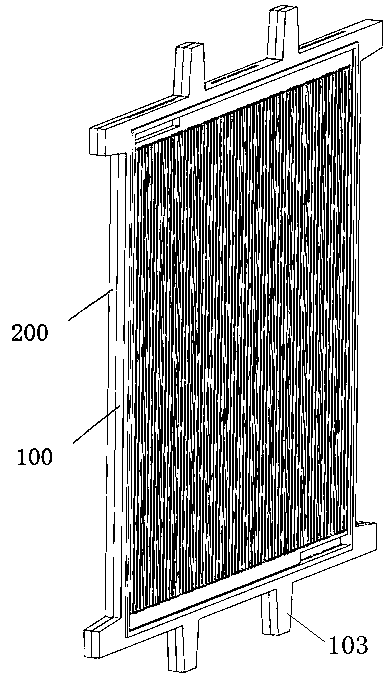

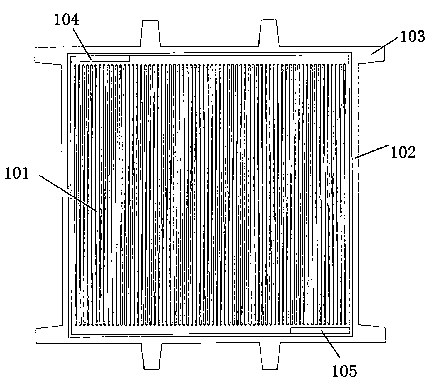

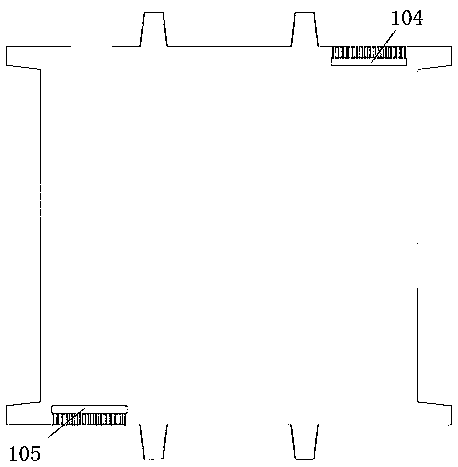

[0028] A kind of high-efficiency full-screen flow field bipolar plate for fuel cells, such as figure 1 As shown, it consists of a single-stage plate on the anode side 100 and a single-stage plate on the cathode side 200 bonded back to back. The single-stage plate on the anode side 100 and the single-stage plate on the cathode side 200 are composed of substrates with the same outer contour. The substrate can be graphite Plate, composite graphite plate or metal plate and other conductive plates, the upper and lower sides and left and right sides of the substrate are provided with protrusions 103 protruding from the side of the substrate. In this embodiment, the middle of each side of the upper and lower sides There are two protruding parts 103 spaced apart by a certain distance, and one protruding part 103 is provided on the upper and lower ends of each side on the left and right sides. The protruding portion 103 is preferably an isosceles trapezoid, the side of the protruding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com